Nylon/Polyester Monofilament mesh

- Delivery Time:

- 7 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

Product Description MAISHI provide precision filter fabrics for liquid filtration, separation and sifting, with special-made processing machines and equipment, MAISHI is capable of heat-slitting mesh into mesh ribbons without fraying edges.

It is widely used in filteration (wather,flour, juices. soybean milk, oil, cheese, air purification, power coating filtering in industry etc. ), printing and dyeing, the industries of petroleum, chemical, metallurgy, cement, environmental dedusting etc.

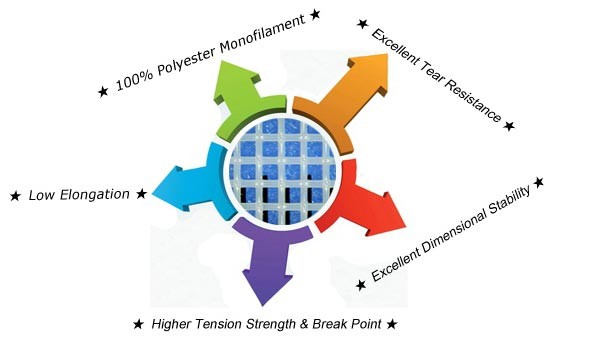

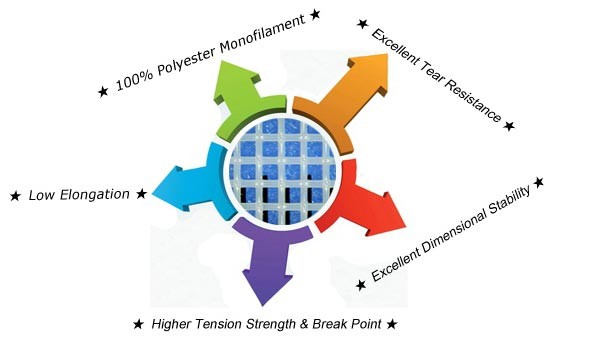

Physical Characteristics Chemical properties Material : manufactured by 100% monofilament nylon or polyester yarn

Opening :the mesh with great precision exact and regular square holes

Dimensional :very good dimensional stability

Temperature : working temperature under 200℃ Chemicals: no unwanted chemicals,no any chemicals treatment in the production process Safe Grade :very safe,very thin,food grade

Monofilament synthetic fibers can be woven very precisely to create industrial textiles with narrow pore distribution. This precision weaving process creates fine mesh woven fabrics with apertures (hole sizes) as small as 50 micron, with a strand and thickness tolerance of +/-10%.

Monofilament synthetic fibers can be woven very precisely to create industrial textiles with narrow pore distribution. This precision weaving process creates fine mesh woven fabrics with apertures (hole sizes) as small as 50 micron, with a strand and thickness tolerance of +/-10%.

We have x-ray heating cutting machine which can nylon filter mesh into any shape and size by your request.

Detailed Images

The construction of plastic cloth is determined by the yarn type, yarn size and thread count. Monofilament yarns are a single continuous filament which produces a relatively smooth surface. In plain weave constructions the straight-through pores of monofilament fabrics offer minimal flow restriction and surface loading of particles.

These versatile precision woven fabrics meet stringent technical requirements in automotive, biomedical, chemical processing, and water treatment applications. Common applications include insert-molded filters for air and fuel filter cartridges, fuel injector nozzles, and liquid filter bags.

Quality Control HEBEI MAISHI dostrictly tested before the goods dispatched from our factory to ensure their quality.Make sure customers get perfect quality.

Quality Control HEBEI MAISHI dostrictly tested before the goods dispatched from our factory to ensure their quality.Make sure customers get perfect quality.

· Mesh Count inspect

· Thickness inspect

· Thread diameter& Hole size inspect

· Tensile Strength inspect

· Surface Tension test

Factory Show Hebei Maishi Printing Mesh Manufacture Factory is one of the top manufacturers and exporters of screen printing mesh.Our company was connected with production of metal wire mesh since 1986 and monofilament polyester screen printing mesh(bolting cloth) and nylon printing meh since 1995, in China. The machinery( Width 3900mm from Switzerland Sulzer and WJ1300/1600 A, B, D) and apparatus used in production process fully based on the high computer technology.

Factory Show Hebei Maishi Printing Mesh Manufacture Factory is one of the top manufacturers and exporters of screen printing mesh.Our company was connected with production of metal wire mesh since 1986 and monofilament polyester screen printing mesh(bolting cloth) and nylon printing meh since 1995, in China. The machinery( Width 3900mm from Switzerland Sulzer and WJ1300/1600 A, B, D) and apparatus used in production process fully based on the high computer technology.

· Dedicated and experienced weavers.

· Consistent quality products.

· On-time delivery.

· We have 15 R&D technical staffs,with more than 10 years experience.

· 80% repeat customers.

· Reasonable claim refund system. Below are the production process

Below are the production process  Packing & Delivery We have two kind of packing type:

Packing & Delivery We have two kind of packing type:

· Fold the mesh into plastic bag, than in carton.

Suitable for small quantity and have no requirement on the crease.

· Pack the mesh with paper and plastic bag, then in carton.

Suitable for large quantity and the mesh has better surface than folding type.

Certificate Maishi emphasize the detail operation and control,make sure the production and service will be made perfectly.If there anything problem of quality,we will compensate or return the goods.

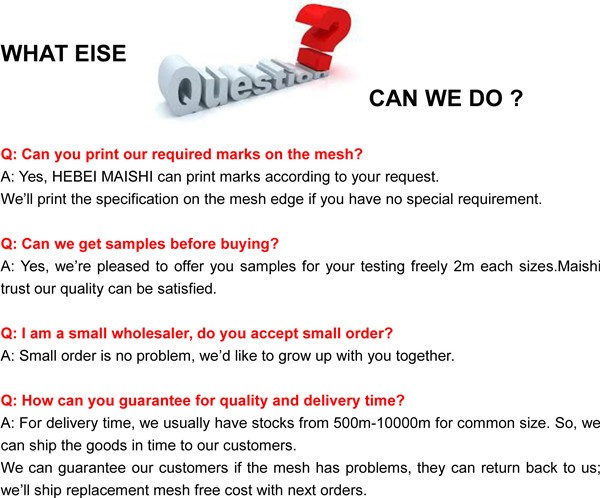

FAQ

FAQ  Contact

Contact

It is widely used in filteration (wather,flour, juices. soybean milk, oil, cheese, air purification, power coating filtering in industry etc. ), printing and dyeing, the industries of petroleum, chemical, metallurgy, cement, environmental dedusting etc.

Physical Characteristics Chemical properties Material : manufactured by 100% monofilament nylon or polyester yarn

Opening :the mesh with great precision exact and regular square holes

Dimensional :very good dimensional stability

Temperature : working temperature under 200℃ Chemicals: no unwanted chemicals,no any chemicals treatment in the production process Safe Grade :very safe,very thin,food grade

Monofilament synthetic fibers can be woven very precisely to create industrial textiles with narrow pore distribution. This precision weaving process creates fine mesh woven fabrics with apertures (hole sizes) as small as 50 micron, with a strand and thickness tolerance of +/-10%.

Monofilament synthetic fibers can be woven very precisely to create industrial textiles with narrow pore distribution. This precision weaving process creates fine mesh woven fabrics with apertures (hole sizes) as small as 50 micron, with a strand and thickness tolerance of +/-10%.We have x-ray heating cutting machine which can nylon filter mesh into any shape and size by your request.

The construction of plastic cloth is determined by the yarn type, yarn size and thread count. Monofilament yarns are a single continuous filament which produces a relatively smooth surface. In plain weave constructions the straight-through pores of monofilament fabrics offer minimal flow restriction and surface loading of particles.

These versatile precision woven fabrics meet stringent technical requirements in automotive, biomedical, chemical processing, and water treatment applications. Common applications include insert-molded filters for air and fuel filter cartridges, fuel injector nozzles, and liquid filter bags.

Quality Control HEBEI MAISHI dostrictly tested before the goods dispatched from our factory to ensure their quality.Make sure customers get perfect quality.

Quality Control HEBEI MAISHI dostrictly tested before the goods dispatched from our factory to ensure their quality.Make sure customers get perfect quality.· Mesh Count inspect

· Thickness inspect

· Thread diameter& Hole size inspect

· Tensile Strength inspect

· Surface Tension test

Factory Show Hebei Maishi Printing Mesh Manufacture Factory is one of the top manufacturers and exporters of screen printing mesh.Our company was connected with production of metal wire mesh since 1986 and monofilament polyester screen printing mesh(bolting cloth) and nylon printing meh since 1995, in China. The machinery( Width 3900mm from Switzerland Sulzer and WJ1300/1600 A, B, D) and apparatus used in production process fully based on the high computer technology.

Factory Show Hebei Maishi Printing Mesh Manufacture Factory is one of the top manufacturers and exporters of screen printing mesh.Our company was connected with production of metal wire mesh since 1986 and monofilament polyester screen printing mesh(bolting cloth) and nylon printing meh since 1995, in China. The machinery( Width 3900mm from Switzerland Sulzer and WJ1300/1600 A, B, D) and apparatus used in production process fully based on the high computer technology. · Dedicated and experienced weavers.

· Consistent quality products.

· On-time delivery.

· We have 15 R&D technical staffs,with more than 10 years experience.

· 80% repeat customers.

· Reasonable claim refund system.

Below are the production process

Below are the production process  Packing & Delivery We have two kind of packing type:

Packing & Delivery We have two kind of packing type:· Fold the mesh into plastic bag, than in carton.

Suitable for small quantity and have no requirement on the crease.

· Pack the mesh with paper and plastic bag, then in carton.

Suitable for large quantity and the mesh has better surface than folding type.

Certificate Maishi emphasize the detail operation and control,make sure the production and service will be made perfectly.If there anything problem of quality,we will compensate or return the goods.

FAQ

FAQ  Contact

Contact

Related Keywords

Related Keywords