2016 Best Selling Corn/ Maize Flour Milling Project for Sale

- Delivery Time:

- 30 Days

Your message must be between 20 to 2000 characters

Contact NowIncludes beating, screening, destoner, magnetic separator and dampening. Different capacity machine line has different number of beat, screen and stoner.

To ensure the flour Quality and the working life of the mill by removing the impurities in the wheat before go to mill,

Beat: Through the beat function of the wheat scourer, brusher to remove dust sand small seed, bacterial count and insect seed.

Screening: To remove large and small impurities in the wheat seed by make the wheat go through vibrating sieve and aspiration sieve.

Destoner: Mainly remove stone in the wheat to protect them milled into the flour and also protect the roller on the milling process.

Magnetic separator: Remove metal material in the wheat to keep the roller safe and also avoid flour exploration accident of spark caused by the impact of the metal impurities and the machine.

Dampening: Dampening the wheat bran before mill to ensure the bran's integrity during the milling processing, avoid the bran going into the flour to keep flour quality. B. The flour milling part:

Include different number of mill and sifter to mill the wheat and separate the flour and bran

(1) Mill: Mill the wheat to break the integrity by the roller moving

(2) Sifter: To separate the flour and bran, also separate large size and small size to enssure flour quality. C. Packing part.

The packing part can be manual one also can be auto one, this can be designed according to requirement and machine capacity. Customer Visting Most of our customers will come and visit our factory befor order to maize flour milling plant.

We can talk with each other face to face for confirming all the details for maize milling machines.

We can talk with each other face to face for confirming all the details for maize milling machines. In our factory, we have installed a maize processing plant for showing our clients.

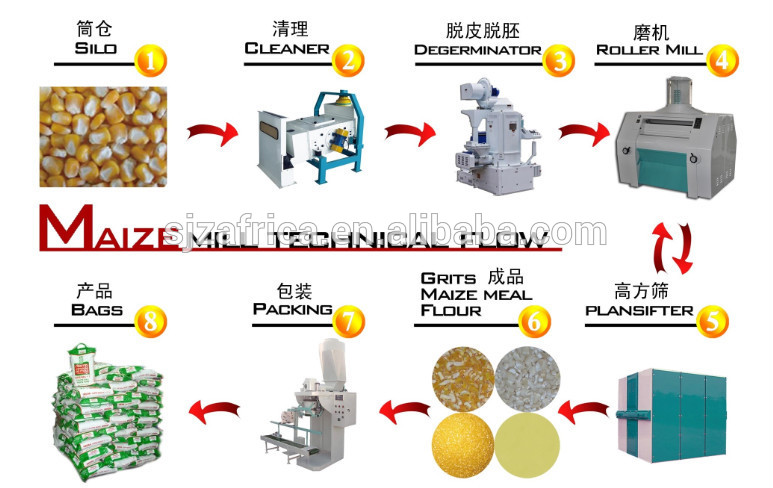

In our factory, we have installed a maize processing plant for showing our clients.Flow Chart for maize The infrmation for maize meal factory. As a professional engineer for installing and operating maize milling machines. We had some general idea for setting up a maize meal factory in Africa. 1. Maize storage. The maize can be from your farm or your local market. It will be stored by silo. and be precleaned by high speed sieve for removing big impurity. Before going silo, the maize moisture content should be less than 14%. So the maize will be dried to keep moisure content less than 14%, so it can go into silo by elevator, and after conveyor , it will go to maize miling plant warehouse. 2. Maize processing plant. Maize cleaning section: It useing vibrating sieve, destoner, magnetic separetor to remove all the big and small impurity. Then we use double floor damper to add water into maize, which is better for peeling and milling. After add water, maize will go to degerminator which is designed by Japan technology and South Africa technoloy. It can scrub the bran skin from maize kernel and to dislodge the germ from its cavity, with minimum reduction in size of broken fragments. 3. Maize milling section: It using roller mill or hammer mill for produce different size maize meal or maize flour. In Kenya, Tanzania, Zambia, Zimbabwe we alway use roller mill for geting super white maize meal. For Uganda, Rwanda,Congo market, we use hammer mill for getting much more fine maize flour. After milling, the maize become maize flour, maize meal or grits. Then the sifter will be graded them. Some part will go to packing and the other part will go back mill to milling again. For packing machine, it will be package 1kg, 2kg, 5kg, 10kg, 20kg, 25kg and 50kg. Different size bags will be used different packing equipments. After packing, it will go to market for human consumption.

Adjustment and Operation of The Equipment A. Maize cleaning part, peeling part and embryo separating part Bucket Elevator III → Beating peeler → Bucket elevator II → Damper → No.5 Low pressure blower →Combined cleaning machine → Bucket Elevator I B. Flour milling part No.5 Blower → Motor for flour discharger → No.5.5 Wide blower → Motor for air seal → No.2 Plansifter → No.1 Plansifter → 4th Break → 3rd Break → 2nd Break → 1st Break

Adjustment and Operation of The Equipment A. Maize cleaning part, peeling part and embryo separating part Bucket Elevator III → Beating peeler → Bucket elevator II → Damper → No.5 Low pressure blower →Combined cleaning machine → Bucket Elevator I B. Flour milling part No.5 Blower → Motor for flour discharger → No.5.5 Wide blower → Motor for air seal → No.2 Plansifter → No.1 Plansifter → 4th Break → 3rd Break → 2nd Break → 1st Break 50T/24H wheat flour milling complete plant was installed in Zimbabwe in 2008. |

50T/24Hwheat flour milling complete plant was installed in Ghana in 2008 |

80T/24H wheat flour milling complete plant was installed in Ethiopia in 2009 |

100T/24H maize milling complete plant was installed in South Africa in 2010. |

100T/24H wheat flour milling complete plant was installed in Zimbabwe in 2010 |

60T/24H wheat flour milling complete plant was installed in Brazil in 2010 |

50T/24H wheat flour milling complete plant was installed in Argentina in 2010 |

20T/24H maize flour milling complete plant was installed in Angola in 2011 |

50T/24H maize flour milling complete plant was installed in Venezuela in 2011 |

100T/24H maize flour milling complete plant was installed in Venezuela in 2011 |

50T/24H maize flour milling complete plant was installed in Uganda in 2011 with steel warehouse and silos. |

30T/24H maize flour milling complete plant was installed in Uganda in 2011 with steel warehouse. |

15T/24H maize flour milling complete plant was installed in Kenya in 2011 |

Branch Office We have branch office in the world for grain flour mill

Branch Office We have branch office in the world for grain flour mill | Johannesburg | South Africa |

| Lusaka | Zambia |

| Multan | Pakistan |

you can check on Google for our factory layout

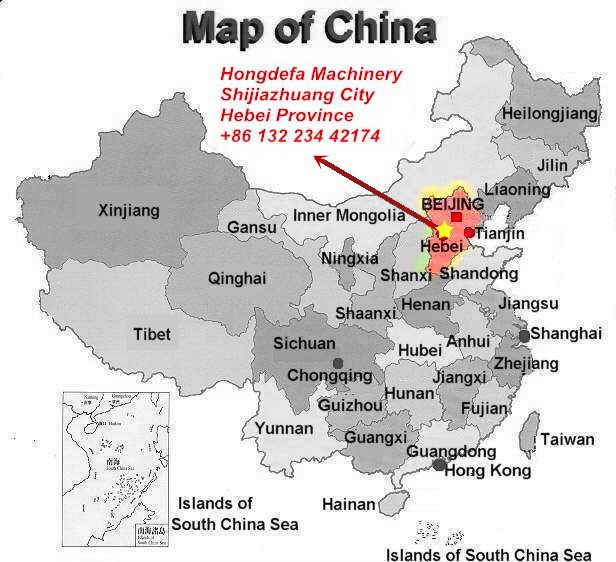

you can check on Google for our factory layout we are location are in Shijiazhuang City, Hebei province. we are near to Beijing. we can pick you at the Beijing Air port. Manufacturing We manufacturing all the machines with high standard equipment

we are location are in Shijiazhuang City, Hebei province. we are near to Beijing. we can pick you at the Beijing Air port. Manufacturing We manufacturing all the machines with high standard equipment  High quality equipment can do high maize mill machines. Install & Test we can send our engineers to your city to help in stallation and train your local stuff how to operate maize mill.

High quality equipment can do high maize mill machines. Install & Test we can send our engineers to your city to help in stallation and train your local stuff how to operate maize mill.

The Engineer are installing maize mill machines in customer factory.

we do good aftersale service: installation, train workkers and testing maize mill plant. contact details 24Hrs Hot Line : +8613223442174 contact person: Jane Liu Skype: jane.liu15 email: jane(at)sjzafrica.com

Related Keywords