Wheat Flour Mill Plant Cost: Bread and Cake Flour Making Line

-

$288000.001-1 set

-

$258000.00≥2 set

- Min. Order:

- 1 set

- Min. Order:

- 1 set

- Port:

- Tianjin port

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 40 Set/Sets per Year |

|---|---|

| Payment Type: | L/C,T/T |

| Port: | Tianjin port |

Complete equipment wheat flour mill plant cost bread cake flour making line

·It can be steel frame building and also can be 4-6 floor building

·Various final products for Bread, Cake, Biscuit, Noodles, Chapatti, Pasta, Etc.

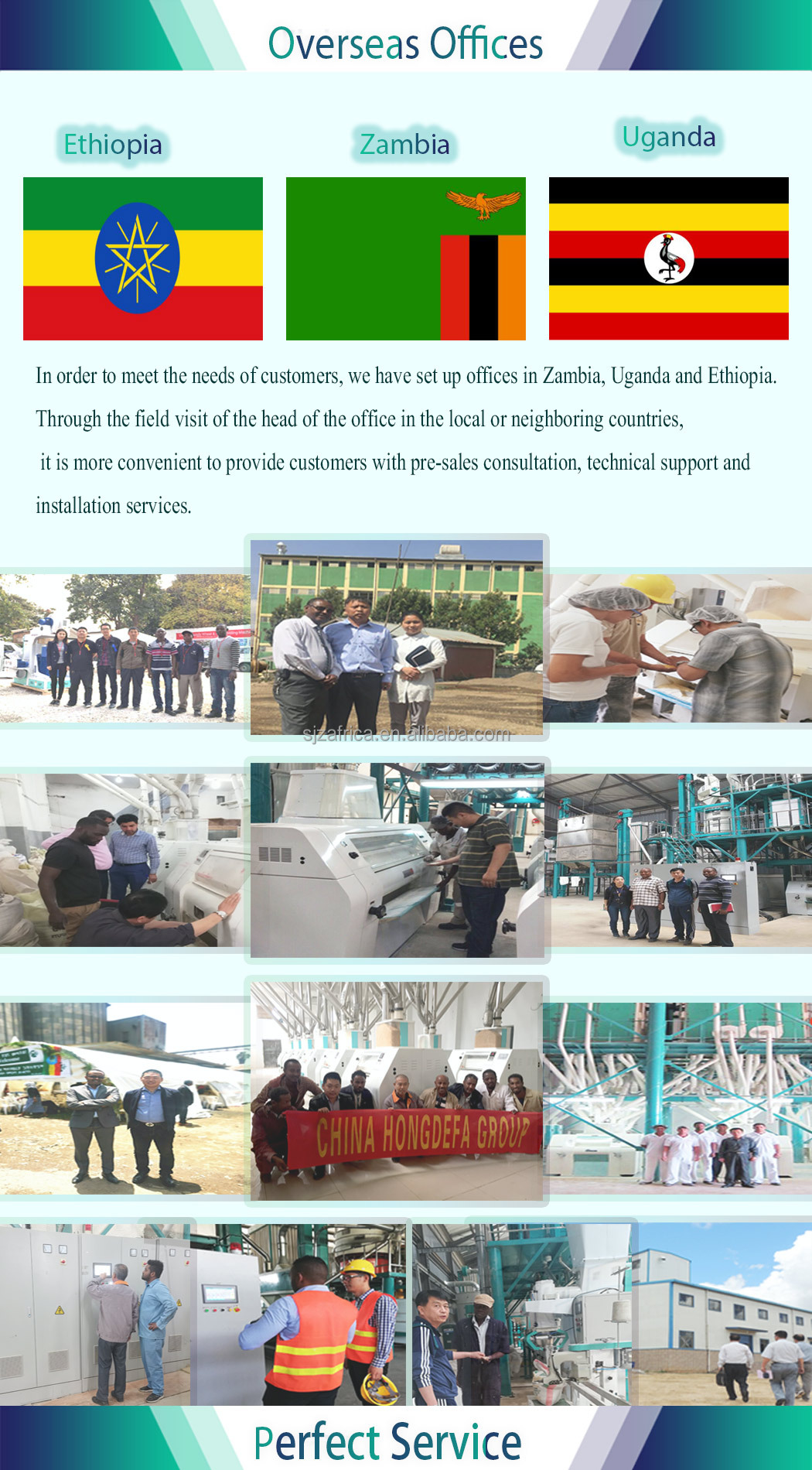

·After service in Addis Ababa/Ethiopia, Lusaka/Zambia and Kampala/Uganda for quick service

·ISO, CE, BV, SGS inspection certificate to confirm the machines good quality

·complete production line from cleaning,mill to packing with all accessories

·Stainless steel pips in flour system, lifetime 3times than normal material pipes

1. Technique flow for the wheat flour mill milling machine line

After finishing cleaning, wheat falling into milling machine. At first, extract much of scratch, particles and dunst with good

quality from wheat, graded them according to particles's size and quality then flowing into purifier. At the same time, the scratch system separate hull and endosperm. That can get pure particles and dunst, then make into top grade flour by reduction system. For the second grade particles and endosperm will mill by the relevant reduction system to get bran flour. The milling flow can divided into different system, that is Break system, Scratch system,Purifier system, Reduction system, Air transportation system, and packing system.

1)The partitioned paneling and swing-out feed module guarantee ideal

access to the feeding and grinding rolls. This makes residue-free

cleaning possible.

2) a pulse generator automatically adjust the feed material at the entrance door

3) bearing SKF

4) temperature monitor (option)

Plansifter in the 120ton/24h wheat flour milling machine :

2)up and down sifter circles with steel plate overall by bending

3)Transmission system using spring force component institutions

4)Sieve frames of wood coated with synthetic resin,without backwire

5)All the inside walls as well as the doors are provided with high-grade insulation

6)Vertical and horizontal clamping system

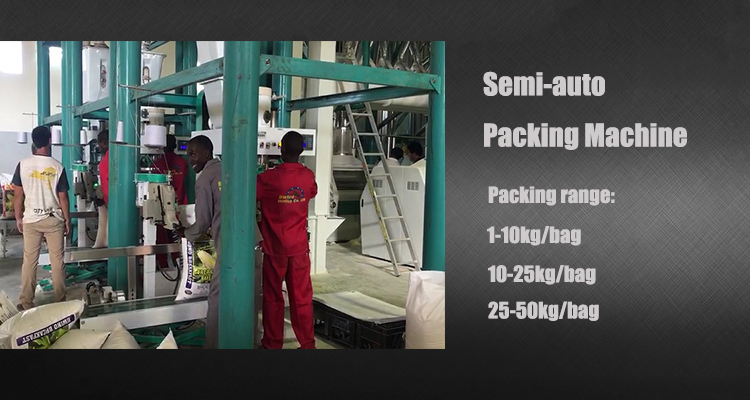

Automatic packing system in the wheat flour milling line:

1) Online auto cumulative weight

2)High-precision on-line flow control;

3)Frequency (batch) weight control;

4)With MODBUS communication interface with computer networking, computer centralized management control;

5) According to customer needs, can have the print function.

6)Feeding and support is stainless steel

Pipes in the the flour milling line: Stainless steel pipes in milling section where contact with

material. Stainless steel pipes is high quality and Antirust the whole line looks beautiful, shinning and cleaning.

Wheat flour milling factory introduction:

(1)Factory with different workshop:

We are a professional manufacturer for wheat mill machine in Shijiazhuang city, China, 300KM from Beijing.

(2) Client visit our factory all over the world

Every year there will be many clients from different countries (such as Zambia Kenya Uganda South Africa Tanzania Benin Ghana Nigeria and so on ) come to our factory in China to check the real wheat mill machines, the running lines which can produce the flour when they come then make the final order.

(3)Special technique team to design the whole wheat flour mill line according to each client special needs.

We have special technique team to design the whole workshop for wheat mill line according to each client special needs, land size and special requirements.

5. Hongdefa Honor

Certificate for flour milling machine

Related Keywords