240T/24H Corn Grinding Flour Milling Line Machine with Good Feedback

-

$358000.001-1 set

-

$340000.002-2 set

-

$335000.00≥3 set

- Min. Order:

- 1 set

- Min. Order:

- 1 set

- Port:

- TIANJIN CHINA OR CUSTOMIZED

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 10 Set/Sets per Month |

|---|---|

| Payment Type: | L/C,Western Union,T/T,MoneyGram,Cash |

| Port: | TIANJIN CHINA OR CUSTOMIZED |

Product Description

Product Description

Product Overview

Power 240T/24H Corn Grinder Flour Grinding Line Mill Machine With Good Feedback

Different countries have different requirements for the final product, such as in Zambia, people like breakfast

maize meal; in Kenya, Zimbabwe, Tanzania, Nigeria, people like fine maize flour; but in Uganda/Rwanda/Burundi,

people like super fine super white maize flour. we can design the corn grinder flour grinding line mill machine according to the needs of your local markets.

maize meal; in Kenya, Zimbabwe, Tanzania, Nigeria, people like fine maize flour; but in Uganda/Rwanda/Burundi,

people like super fine super white maize flour. we can design the corn grinder flour grinding line mill machine according to the needs of your local markets.

Product Details

Capacity | Process 240tons raw corn per 24hours | ||||||

Final Product | Different sizes of corn flour, corn meal, corn grits, germ and bran | ||||||

Warehouse Size | 42*12*12m (L*W*H) | ||||||

Container | 9*40' | ||||||

Installation and commission | About 2 months | ||||||

Power 240T/24H Corn Grinder Flour Grinding Line Mill Machine

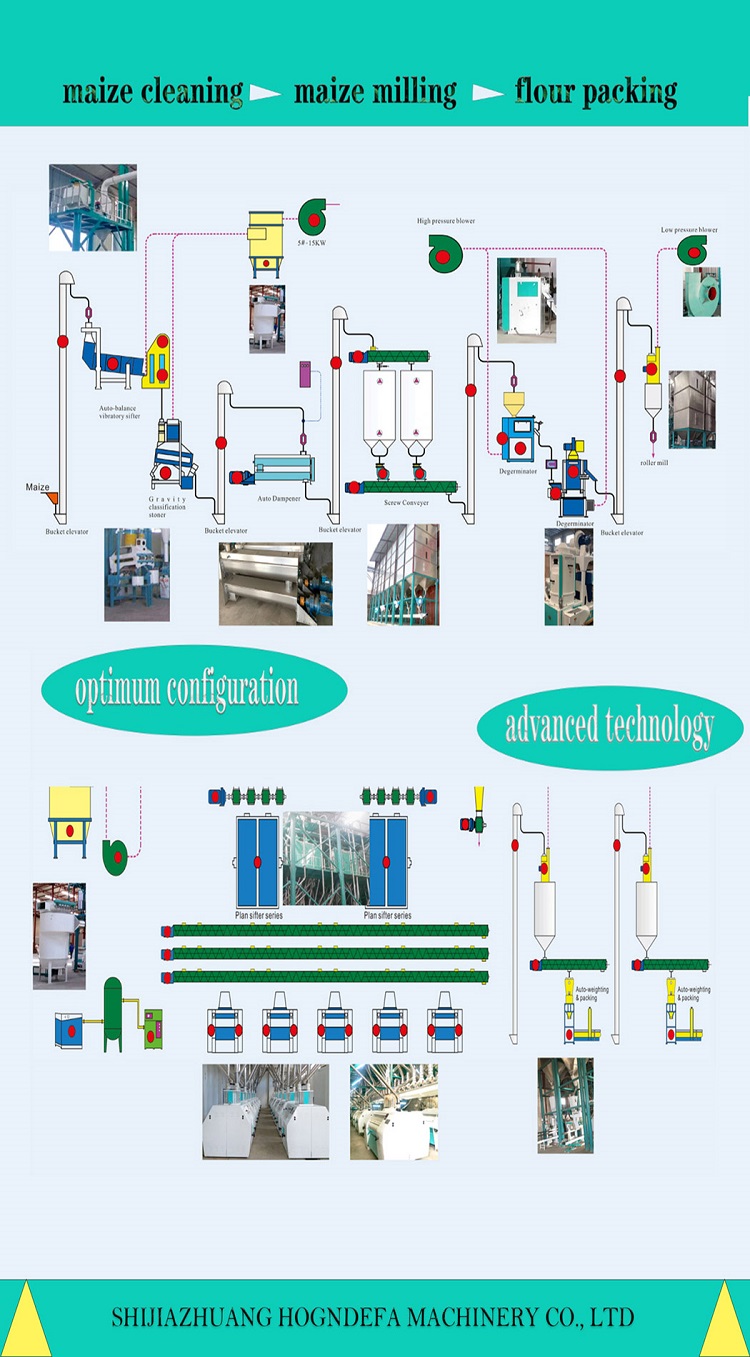

It is from A to Z, means from start to end. such as corn cleaning machines-dampering-degerminating-roller milling-sifting-packing-control system.

1. Main Machine Details

All corn mill machines are configured with the most suitable equipment according to the production line,

Including pneumatic mill, plan sifter, degerminater,vibrating cleaning sifter, stone remover and auto dampener. etc.

Provide the most perfect solution with the most advanced configuration, the highest quality and the lowest consumption.

Including pneumatic mill, plan sifter, degerminater,vibrating cleaning sifter, stone remover and auto dampener. etc.

Provide the most perfect solution with the most advanced configuration, the highest quality and the lowest consumption.

Corn Grinder Flour Grinding Line Mill Machine Flow Chart

Hongdefa corn mill machine technique flow is from cleaning to degerminating to milling to sifting to packing.

First,the maize enter the cleaning section,have gravity classification stoner remove the stone,then through the moisture damper is a important equipment to control the water content of the grain during in flour mills,stainless steel Bi-directional screw,prevent free water,an intensive intermixing.Next use degerminator (Japan technology ) to peeling,Then enter the milling section and sifting the flour,produce the produce super white flour,fine meal,bran,germ,etc which according to client requirement and needs.Finally,use the autoweighing &packing scale packing products.

First,the maize enter the cleaning section,have gravity classification stoner remove the stone,then through the moisture damper is a important equipment to control the water content of the grain during in flour mills,stainless steel Bi-directional screw,prevent free water,an intensive intermixing.Next use degerminator (Japan technology ) to peeling,Then enter the milling section and sifting the flour,produce the produce super white flour,fine meal,bran,germ,etc which according to client requirement and needs.Finally,use the autoweighing &packing scale packing products.

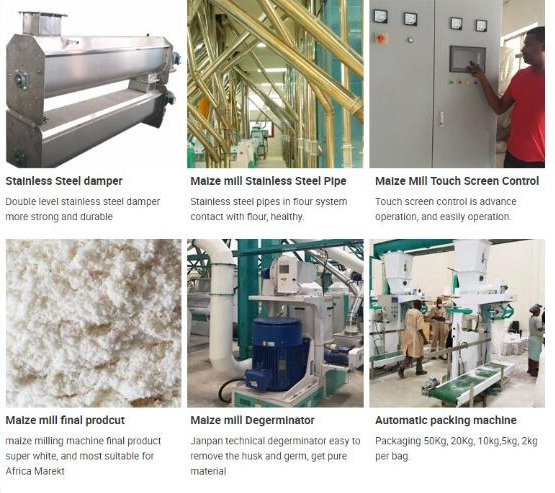

Pneumatic roller mill

Stainless steel double layer damper

Janpan technology degerminator

Touch Screen Control System/ PLC Control System

2. The Final Product of Corn Grinder Flour Grinding Line Mill Machine

Our Corn Flour Milling Machine can process both white corn and yellow corn can produce super fine corn flour, refine corn flour, corn meal, corn grits, maize samp, semoule, etc, you can make Ugali, Sadza, Nshima,Fufu, Snacks food. The by-product maize germ can make oil, the maize bran can make animal feeds.

3. After sales Service

--- Equipment Installation

Our professional technicians offer the guidance of installation, commissioning the corn flour milling machines,

---Training Provide

Training workers which is helpful to guarantee the normal operation of the corn flour milling plant and to ensure the quality of finished products.

--- Fixing and Maintenance

If clients needs, our engineers can come to visit the site and give more advice face to face.

---Spare Parts Supply

Available from Lusaka/Zambia Office timely where have put a big storage room and delivery door to door.

Our professional technicians offer the guidance of installation, commissioning the corn flour milling machines,

---Training Provide

Training workers which is helpful to guarantee the normal operation of the corn flour milling plant and to ensure the quality of finished products.

--- Fixing and Maintenance

If clients needs, our engineers can come to visit the site and give more advice face to face.

---Spare Parts Supply

Available from Lusaka/Zambia Office timely where have put a big storage room and delivery door to door.

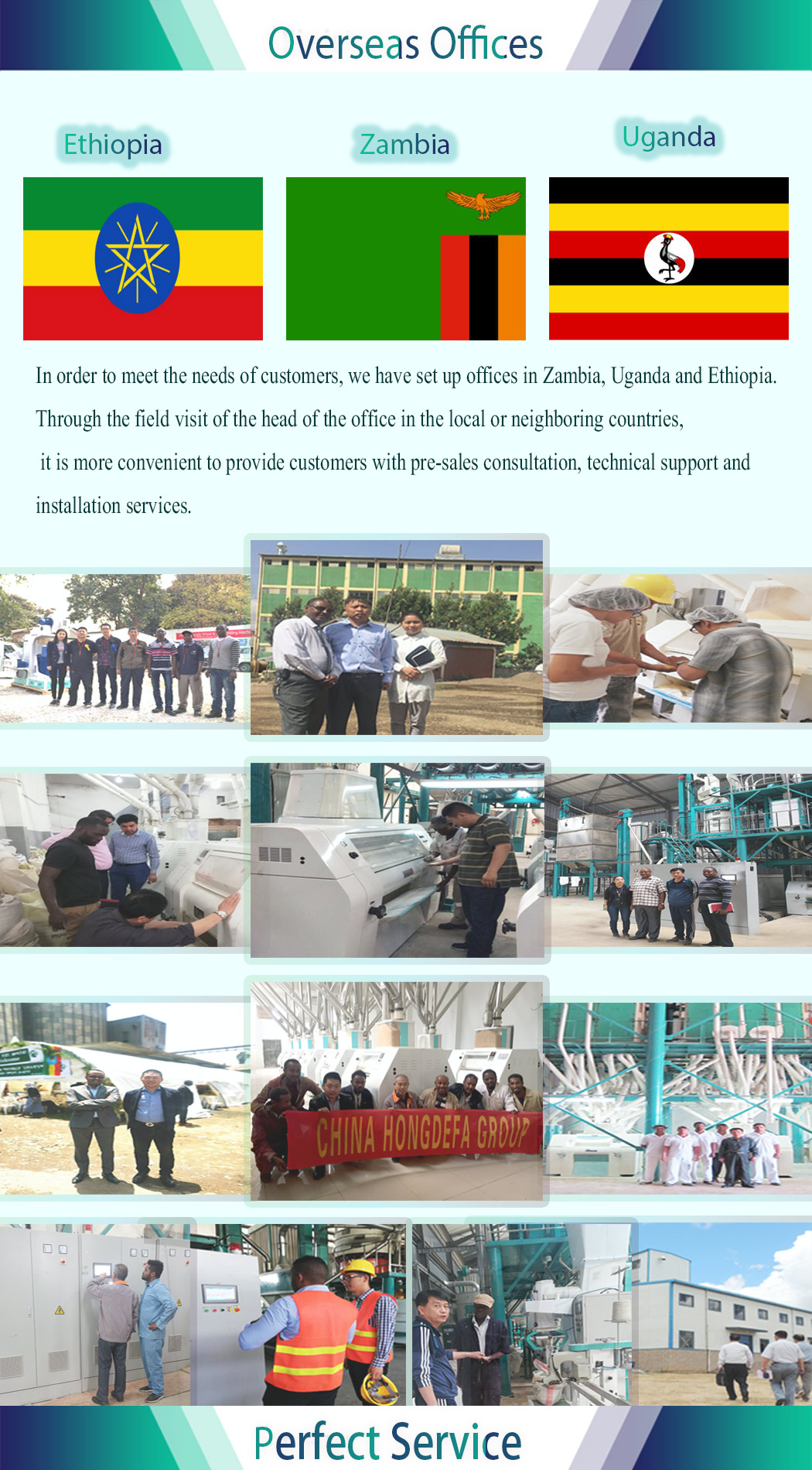

4. Oversea Offices

We have three overseas offices: Ethiopia office, Zambia office and Uganda office.

Engineers have been stationed overseas for a long time.so it is very convenient to provide Pre-sales consultation and after-sales service

Engineers have been stationed overseas for a long time.so it is very convenient to provide Pre-sales consultation and after-sales service

5. Patent for Corn Grinder Flour Grinding Line Mill Machine

All our corn flour mill machines are high quality and have passed the certification of ISO, CE, BV, SGS and COC.

And we have Drum Sifter Patent, degerminator Patent and Gravity Table Patent.

And we have Drum Sifter Patent, degerminator Patent and Gravity Table Patent.

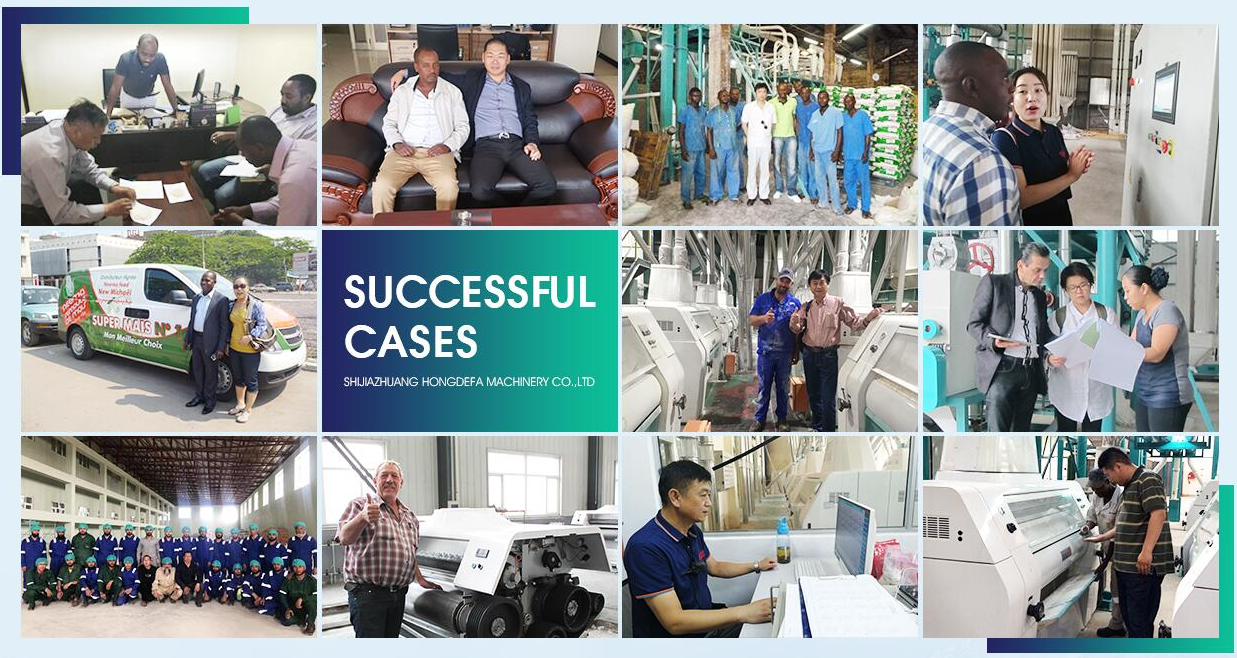

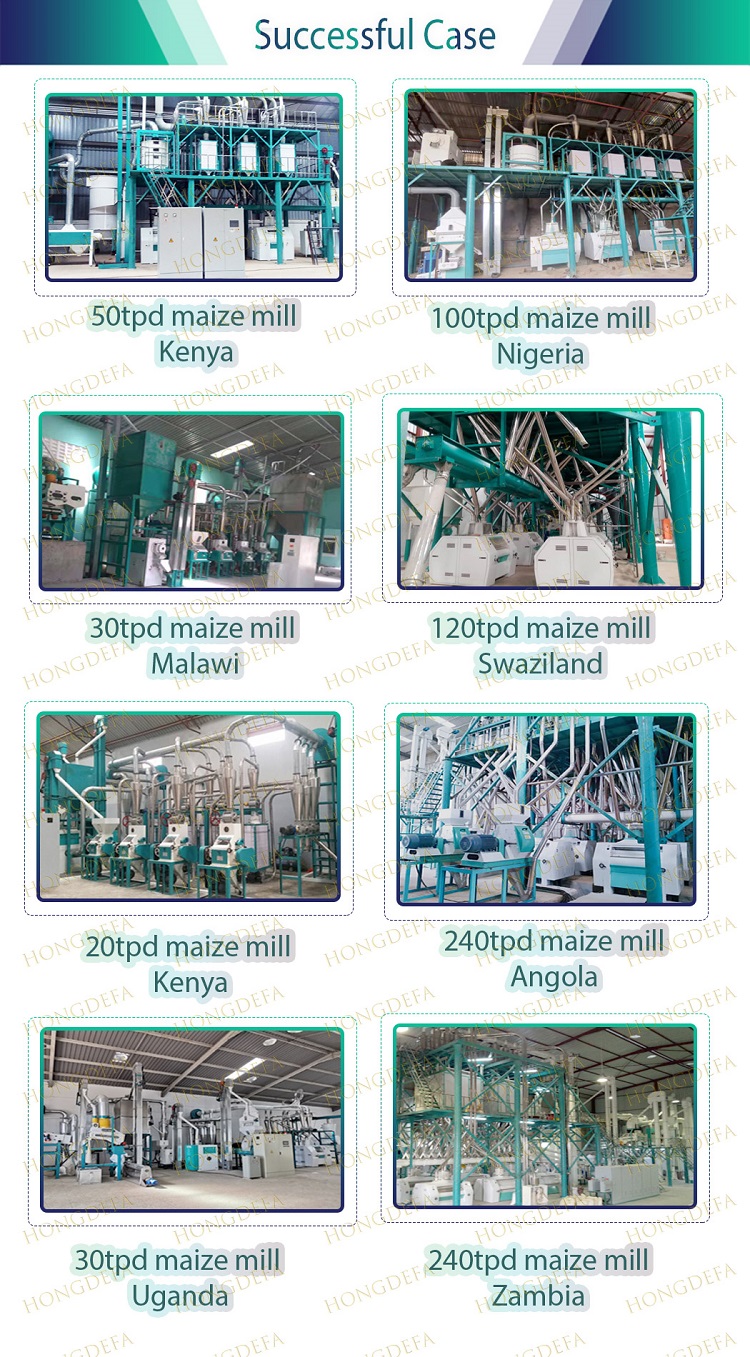

6. Successful Project

1500t/24h corn flour mill machine in South Africa(China largest export mill line);

1000t/24h maize mill machine in Australia;

500t/24h wheat milling plant in Ethiopia;

300t/24h wheat milling plant in Afghanistan;

250t/24h wheat milling plant in Egypt;

240t/24h maize milling plant in Zambia;

200t/24h wheat milling plant in Brazil;

150t/24h corn milling plant in Kenya;

120t/24h corn milling plant in China;

100t/24h maize milling plant in Nigeria;

70t/24h maize milling plant in India;

50t/24h maize milling plant in Mozambique;

And so on.

1000t/24h maize mill machine in Australia;

500t/24h wheat milling plant in Ethiopia;

300t/24h wheat milling plant in Afghanistan;

250t/24h wheat milling plant in Egypt;

240t/24h maize milling plant in Zambia;

200t/24h wheat milling plant in Brazil;

150t/24h corn milling plant in Kenya;

120t/24h corn milling plant in China;

100t/24h maize milling plant in Nigeria;

70t/24h maize milling plant in India;

50t/24h maize milling plant in Mozambique;

And so on.

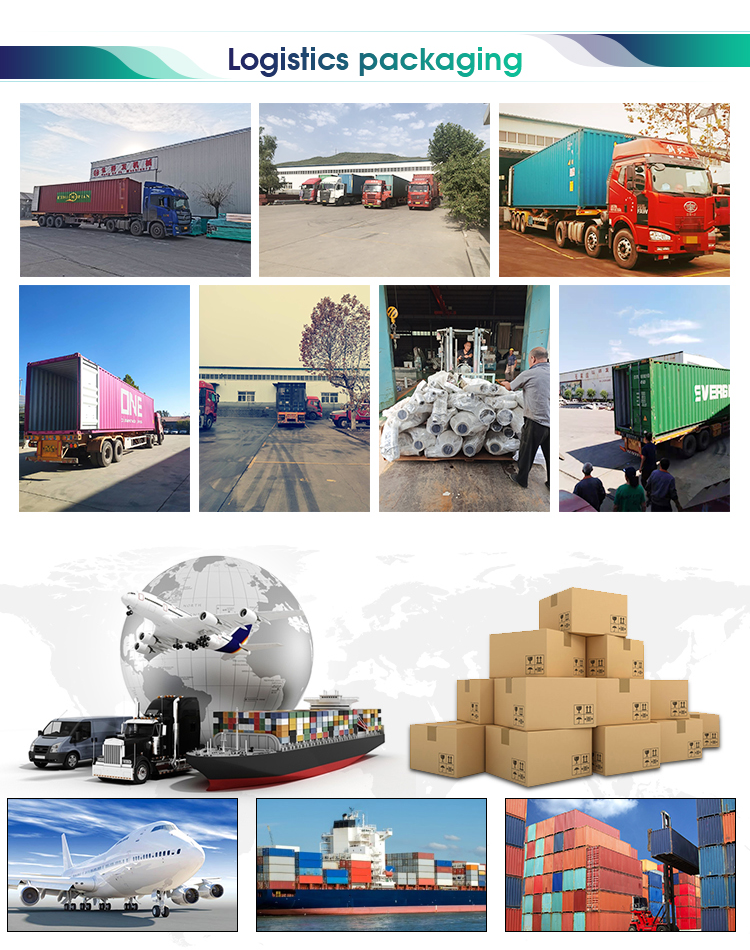

7. Package and Logistic

The machines will be put into the container, then will ship to your city by sea.

Spare parts will be packed in carton or iron box, and then shipped to your city by sea or air.

Hongdefa Factory

Hongdefa has approximately 120 workers, a manufacturing factory of 50000 square meters, and 5000 square

meters of production workshop, 6000 square meters warehouses, 1000 square meters of office space

meters of production workshop, 6000 square meters warehouses, 1000 square meters of office space

Q:What mill does Hongdefa machine use?

A: Pneumatic Roller Mills

The partitioned paneling and swing-out feed module guarantee ideal access to the feeding and grinding rolls.

This makes residue-free cleaning possible.

And the pulse generator can automatically adjust the feed at the entrance, saving time and effort

Q:What is the function of the Degerminator?

A: maize degerminator is applicable for taking the germ and bran out of the maize, at the same time polishing the

maize/maize grits,get pure white /yellow maize meal,maize grits,maize samp, and is characteristic of high volume

of production, compact structure and convenient maintenance, thus making it an ideal equipment for maize processing

in the modern age.

Q:Can I use this machine to produce different sizes maize flour?

A: Yes. In the sifter, we will give you different hole size of mesh screens, to get the different size of final products.

Q: Can the corn flour mill machine also process wheat?

No,it is because the maize and wheat Physical Characteristics is different,like the shape,the hardness, all are different,

and the final product flour size is also different. The cleaner,the roller mill parameter, the plansifter sieve all are different.

As professional manufacture for maize meal or flour,cannot process maize and wheat same time.

Q: Can an automatic packing machine be used to pack 1kg 2kg 5kg 10kg 20kg 25kg 50kg bags?

A: No, they need three kinds of automatic packing machine, like 1-5kg, 10-20kg and 25-50kg.

Q:Can you provide engineer to install the machine?

A: Yes. We can arrange Chinese engineer to go to your city to guide the installation and commissioning of machine.

A: Pneumatic Roller Mills

The partitioned paneling and swing-out feed module guarantee ideal access to the feeding and grinding rolls.

This makes residue-free cleaning possible.

And the pulse generator can automatically adjust the feed at the entrance, saving time and effort

Q:What is the function of the Degerminator?

A: maize degerminator is applicable for taking the germ and bran out of the maize, at the same time polishing the

maize/maize grits,get pure white /yellow maize meal,maize grits,maize samp, and is characteristic of high volume

of production, compact structure and convenient maintenance, thus making it an ideal equipment for maize processing

in the modern age.

Q:Can I use this machine to produce different sizes maize flour?

A: Yes. In the sifter, we will give you different hole size of mesh screens, to get the different size of final products.

Q: Can the corn flour mill machine also process wheat?

No,it is because the maize and wheat Physical Characteristics is different,like the shape,the hardness, all are different,

and the final product flour size is also different. The cleaner,the roller mill parameter, the plansifter sieve all are different.

As professional manufacture for maize meal or flour,cannot process maize and wheat same time.

Q: Can an automatic packing machine be used to pack 1kg 2kg 5kg 10kg 20kg 25kg 50kg bags?

A: No, they need three kinds of automatic packing machine, like 1-5kg, 10-20kg and 25-50kg.

Q:Can you provide engineer to install the machine?

A: Yes. We can arrange Chinese engineer to go to your city to guide the installation and commissioning of machine.

Related Keywords

Related Keywords

You May Also Like

You May Also Like