Fully Automatic Wheat Milling and Flour Production Plant Machinery

-

$300000.001-1 set

-

$280000.00≥2 set

- Min. Order:

- 1 set

- Min. Order:

- 1 set

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

Product Description

Product Description

About our Product

Industrial Fully Automatic Wheat Milling Flour Mill Production Plant Flour Making Machine

1. Turnkey project

2. Advanced technology support and customized design.

3. Thorough crafts and rational allocation.

4. Low power consumption.

5. Perfect after-sales service.

6. Two year guarantee.

2. Advanced technology support and customized design.

3. Thorough crafts and rational allocation.

4. Low power consumption.

5. Perfect after-sales service.

6. Two year guarantee.

Model | HDF 62t/24h Wheat Milling Machine | ||||||

Production Capacity | Processing 62 ton raw wheat in 24hrs | ||||||

Main machines | The pipe in milling section is stainless steel, and moisture bin is stainless steel | ||||||

Final Products | High quality wheat flour for making bread,cake,biscuit,pasta,macaroni | ||||||

Products quality index | 70%-82% | ||||||

Power required (KW) | Electricity 380V/440V 50Hz/60Hz 3phase | ||||||

Size of workshop(L×W×H, m) | 36x8x7.5m (LxWxH) | ||||||

42t/24h Industrial Fully Automatic Wheat Milling Flour Mill Production Plant

Warranty: 5 years

Processing: Cleaning-milling-packing.

Pipes: Stainless steel pipes

Control panel: Button control

Location: Ethiopia

62t/24h Industrial Fully Automatic Wheat Milling Flour Mill Production Plant

Warranty: 5 years

Processing: Cleaning-milling-packing.

Pipes: Stainless steel pipes

Control panel: Touch screen control

Location: Ethiopia

Pipes: Stainless steel pipes

Control panel: Touch screen control

Location: Ethiopia

120t/24h Industrial Fully Automatic Wheat Milling Flour Mill Production Plant

Warranty: 5 years

Processing: Cleaning-milling-packing.

Pipes: Stainless steel pipes

Control panel: Touch screen control

Pipes: Stainless steel pipes

Control panel: Touch screen control

Standard: European standard wheat milling machine

Location: Ethiopia

Location: Ethiopia

Hongdefa 300t/24h Industrial Fully Automatic Wheat Milling Flour Mill Production Plant

Warranty: 5 years

Automatic wheat flour mill from Cleaning,milling to packing.

PLC control.

Pneumatic roller mill machine.

Pneumatic roller mill machine.

Processing flow about Industrial Fully Automatic Wheat Milling Flour Mill Production Plant

Input wheat –>wheat cleaner–> wheat moisture dampener–>roller mill–>plansifter–>good quality flour –>packing

After finishing cleaning, wheat falling into milling machine. At first, extract much of scratch, particles and dunst with good

quality from wheat, graded them according to particles's size and quality then flowing into purifier. At the same time, the

scratch system separate hull and endosperm. That can get pure particles and dunst, then make into top grade flour by reduction system. For the second grade particles and endosperm will mill by the relevant reduction system to get bran flour. The milling flow can divided into different system, that is Break system, Scratch system,Purifier system, Reduction system, Air transportation system, and packing system.

The introduction as below:

1. Break system:The function of the first break system is to break off the wheat and without break the bran. That scrape the big size endosperms away from the wheat, and the rear break system to scrape all the endosperms from bran.

2. Scratch system: The function of scratch system is to separated the bran and endosperm from the reduction system. After this will get good quality endosperm through sifter. The scratch system processing the small size of the material which are not suitable for next break and also not suitble for reduction system, because of the endosperm not pure.

3. Purifier system: Purifier function is picking the scratch, particles, and hard dust which from break system and scratch system to get bran, endosperm with some bran, and pure endosperm according to the quality. That can let only the pure endosperm falling into the reduction system to avoid the bran spoiled the flour, to increase the flour quality.

4. Reduction system:The reduction system is to grinding the endosperm which from break system and purifier, as the same time to grinding the wheat husks and embryo at least. The reduction system adpot smooth roller, can press bran and embryo to flake as the same time grinding the endosperm into the fine powder. Because of the different size among wheat husks, endosperm and embryo,through the impacting detacter, the endosperm will be grinding properly, and the wheat husks and embryo will be make flake. After sifting, it can separate flour from ban and embryo.

5. Air transportation system: Air transportation system is a tie for grinding, sifting and other assistant machine. Air

transportation system can supply power by high pressure blower, through the material pipes and special equipment the grinding material will be send to the sifter to sift and classificating to get flour.

6. Packing system: The packing system function is weigh, sewing.

Packing system: Wheat flour packaging machine can packing with different kind of bags, like 1kgs/2kgs/5kgs/10kgs

After finishing cleaning, wheat falling into milling machine. At first, extract much of scratch, particles and dunst with good

quality from wheat, graded them according to particles's size and quality then flowing into purifier. At the same time, the

scratch system separate hull and endosperm. That can get pure particles and dunst, then make into top grade flour by reduction system. For the second grade particles and endosperm will mill by the relevant reduction system to get bran flour. The milling flow can divided into different system, that is Break system, Scratch system,Purifier system, Reduction system, Air transportation system, and packing system.

The introduction as below:

1. Break system:The function of the first break system is to break off the wheat and without break the bran. That scrape the big size endosperms away from the wheat, and the rear break system to scrape all the endosperms from bran.

2. Scratch system: The function of scratch system is to separated the bran and endosperm from the reduction system. After this will get good quality endosperm through sifter. The scratch system processing the small size of the material which are not suitable for next break and also not suitble for reduction system, because of the endosperm not pure.

3. Purifier system: Purifier function is picking the scratch, particles, and hard dust which from break system and scratch system to get bran, endosperm with some bran, and pure endosperm according to the quality. That can let only the pure endosperm falling into the reduction system to avoid the bran spoiled the flour, to increase the flour quality.

4. Reduction system:The reduction system is to grinding the endosperm which from break system and purifier, as the same time to grinding the wheat husks and embryo at least. The reduction system adpot smooth roller, can press bran and embryo to flake as the same time grinding the endosperm into the fine powder. Because of the different size among wheat husks, endosperm and embryo,through the impacting detacter, the endosperm will be grinding properly, and the wheat husks and embryo will be make flake. After sifting, it can separate flour from ban and embryo.

5. Air transportation system: Air transportation system is a tie for grinding, sifting and other assistant machine. Air

transportation system can supply power by high pressure blower, through the material pipes and special equipment the grinding material will be send to the sifter to sift and classificating to get flour.

6. Packing system: The packing system function is weigh, sewing.

Packing system: Wheat flour packaging machine can packing with different kind of bags, like 1kgs/2kgs/5kgs/10kgs

/25kgs/50kgs.

Details introduction

Pneumatic roller mill machine

The mill the most important one machine of whole processing line, is mainly for grinding. To break wheat and bran's structure, and spearate the wheat husk and the embryo from endosperm by grinding.

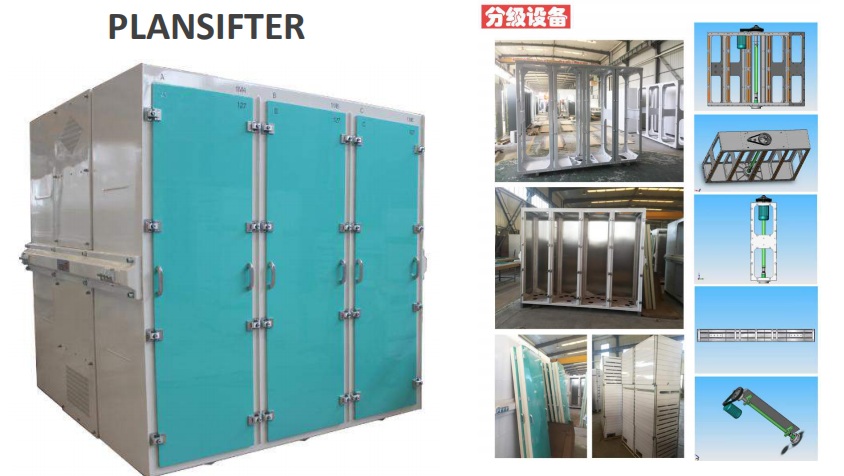

Plansifter

It can classify the material that from break, reduction and scratch systems and sifting the flour.

Purifier

It can get the pure endosperm by sifting which is depending on self-vibration and lower pressure blower's wind power.

Stainless steel pipes

The pipes in milling section where contact with flour are stainless steel pipes. Much more durable.

Automatic packing machine

Automatic detect weight; automatic measure the number of the bags.

It has different packing weight: 10 kg 12.5 kg 20 kg 25 kg and 50 kg

It has different packing weight: 10 kg 12.5 kg 20 kg 25 kg and 50 kg

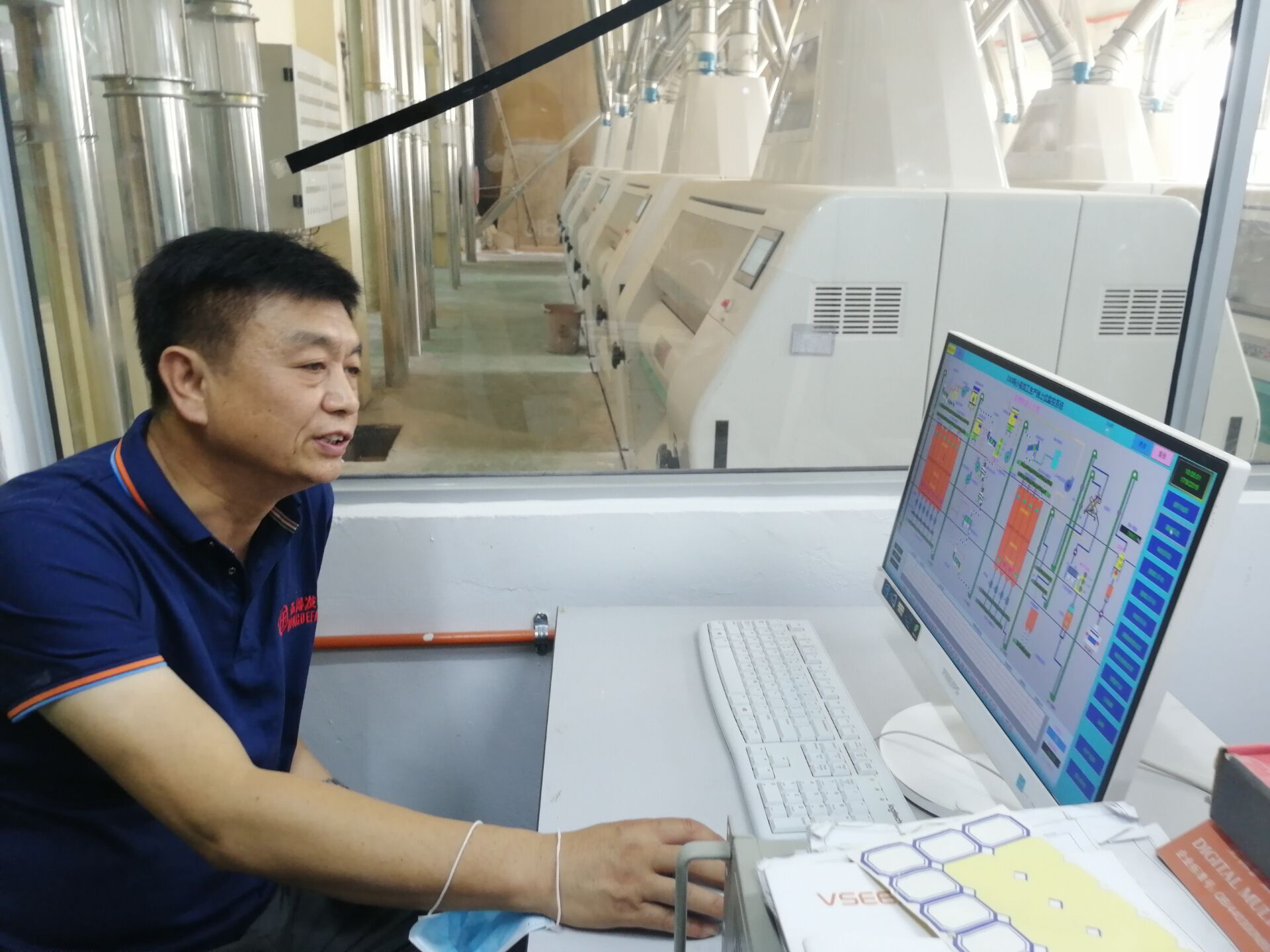

Engineer teaching overseas

Supply engineer installing wheat flour mill overseas.

Engineer will training and teaching local workers for free during the time in client's factory

Packing&delivery

Do inspection before shipping

Do SGS inspection before Industrial Fully Automatic Wheat Milling Flour Mill Production Plant shipping.

Loading containers in Hongdefa factory

All Industrial Fully Automatic Wheat Milling Flour Mill Production Plant are loading and fixed in the container,it suitable for

sea transport. Contact with us for wheat milling machine now!

sea transport. Contact with us for wheat milling machine now!

Hongdefa Factory

Hongdefa professional in Industrial Fully Automatic Wheat Milling Flour Mill Production Plant manufacture

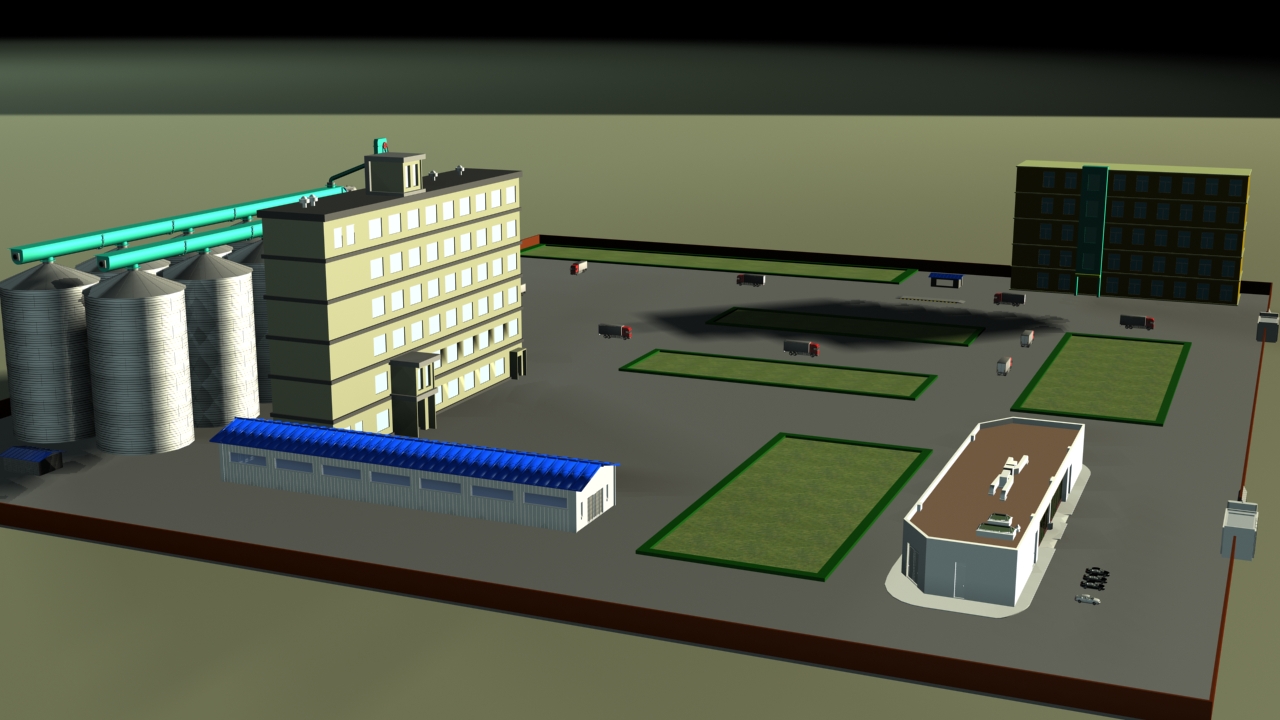

Shijiazhuang Hongdefa Machinery Co.,Ltd is located in Wumashan industrial park, Zanhuang County, Shijiazhuang City, 1 hours by high speed train or 4 hours by car From Beijing.

Hongdefa has approximately 120 workers, a manufacturing factory 50000 square meters, and 5000 square meters of production workshop, 6000 square meters warehouses, 1000 square meters of office space.

Hongdefa has approximately 120 workers, a manufacturing factory 50000 square meters, and 5000 square meters of production workshop, 6000 square meters warehouses, 1000 square meters of office space.

Certificate

OUR SERVICE:

--->Pre-sales Consultation

We can design the processing technology according to your requirements.

---> Equipment Installation

Our professional technicians offer the guidance of installation, commissioning the machines,build up the workshop building and silos,and we can also help to reform the old workshop building as per customers' condition.

--->Spare Parts Supply

Normally we will send you some wearing parts available for one-year operation of the equipment in our first order. When you are in need of new spare parts in the future, we can send directly from Lusaka/Zambia Office timely where have put a big storage room and delivery door to door.

We can design the processing technology according to your requirements.

---> Equipment Installation

Our professional technicians offer the guidance of installation, commissioning the machines,build up the workshop building and silos,and we can also help to reform the old workshop building as per customers' condition.

--->Spare Parts Supply

Normally we will send you some wearing parts available for one-year operation of the equipment in our first order. When you are in need of new spare parts in the future, we can send directly from Lusaka/Zambia Office timely where have put a big storage room and delivery door to door.

Successful Project

Ethiopia 500t/24h wheat flour mill machine

Malaysia 300t/24h wheat flour mill machine

Afghanistan 300t/24h wheat flour mill machine

Egypt 150t/24h wheat flour mill machine

Ethiopia 80t/24h wheat flour mill machine

Peru 60t/24h wheat flour mill machine

42t/24h wheat flour mill machine

Supply silo from 500t to 10000t

Supply 3D factory design free

Q1. Does the wheat flour mill can produce different kind of wheat flour same time?

Yes,the wheat flour mill can produce different size wheat flour at same time at one production line

Q2. Does the wheat flour mill can running with Generator?

Yes,the wheat flour mill can running with Generator

Q3. Does the wheat flour mill can pack different bags?

Yes,the packing machine can pack 1kg-5kg;5kg-20kg,12.5kg-25kg,50kg

Q4. Does the wheat flour mill can processing maize and wheat same time?

No,Maize machine is just for maize,wheat machine is just for wheat .Maize and wheat the Physical Characteristics is

different,like the kernel size,the structure of the kernel and the hardness is all different.The final product size is also

different.All this decide the machine cleaning milling system is different.

different,like the kernel size,the structure of the kernel and the hardness is all different.The final product size is also

different.All this decide the machine cleaning milling system is different.

Related Keywords

Related Keywords

You May Also Like

You May Also Like