Flour Milling Plant: Boost Production Efficiency at the Most Cost-Effective Price

-

$15000.00≥1 set

- Min. Order:

- 1 set

- Min. Order:

- 1 set

Your message must be between 20 to 2000 characters

Contact NowFlour Milling Plant to Boost Your Production Efficiency With The most cost-effective price

The company's equipment is equipped with the most advanced technology and professional technical teams. It has served hundreds of customers and is very famous in the entire African market.

|

Product Name |

Different capacity of flour milling plant |

|

Final Product |

Breakfast meal, roller meal, germ and bran |

|

Flour Extraction |

Adjustable, depending on different clients' requirements |

|

Material |

The pipes in milling section is stainless steel, and the moisture bin is stainless steel |

|

Main machine |

Japan technology degerminator, European standard Pneumatic roller mill, Plansifters |

|

Packing machine |

Electronic scales and automatic sealing machines&Automatic packaging machine |

|

Control system |

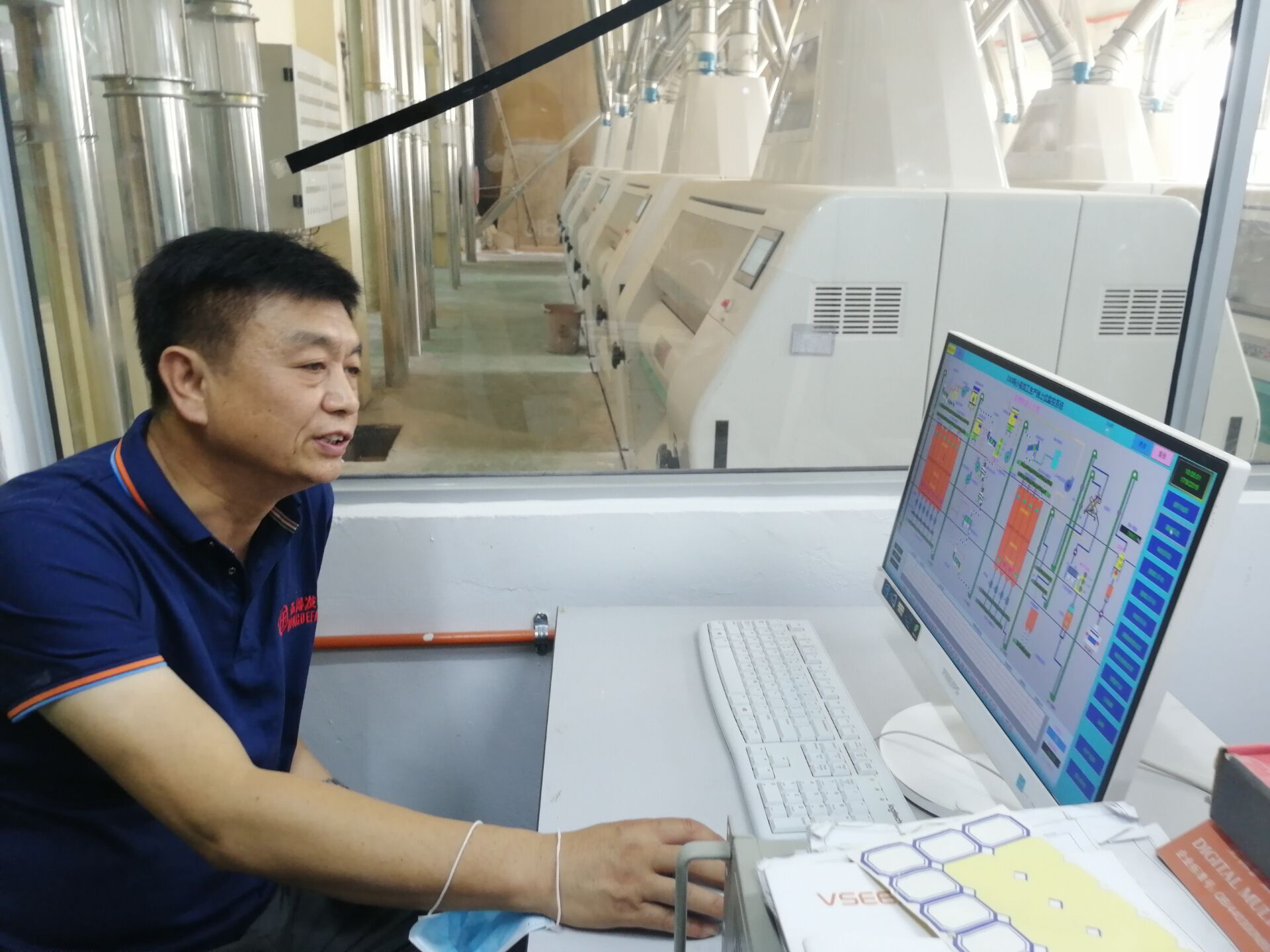

PLC control system |

|

Certificate |

CE, BV, SGS,PVOC,COC, SONCAP,ISO |

|

Power |

Electricity 380V/440V 3phase 50Hz/60Hz |

|

Project |

Kitwe/Zambia; Windhoek/Namibia;Lagos/Nigeria; Nairobi/Kenya,etc |

These are our flour milling plants which running in Africa.

They can produce the super white quality maize meal which is popular in the local market.

Our maize mill plant ensures maximum yield with minimal waste, making your production process more efficient and cost-effective.

Our clients have given high evaluations. Every year, our Chinese engineer goes there to do some maintenance for 1 week.

Flow Chart

All flour miling plants are configured with the most suitable equipment according to the production line,

Provide the most perfect solution with the most advanced configuration, the highest quality, and the lowest consumption.

Final Product

The maize flour can be used for making food like Ugali, Fufu, Sadza,Nshima etc.

Maize grits can for making snacks food,

Maize bran can make animal feeds ,

Maize germ can make oil.

Machine Details Show:

The mill the most important machine of the whole processing line, is mainly for grinding.

The mill the most important machine of the whole processing line, is mainly for grinding.To break maize and bran's structure, and separate the maize husk and the embryo from endosperm by grinding.

NO.1 IN CHINA FOR PLAN SIFTER IN MAIZE MILL FACTORY.

1) Material: High-strength alloy steel which is very strong in maize mill factories.

2) Up and down sifter circles with steel plate overall by bending.

3) Transmission system using spring force component institutions.

4) Sieve frames of wood coated with synthetic resin, without a backfire.

5) All the inside walls, as well as the doors, are provided with high-grade insulation.

6) Vertical and horizontal clamping system.

The degerminator is designed to scrub the bran skin of the maize kernel and dislodge the germ from its cavity, with minimum reduction in the size of the broken fragments.

The degerminator is designed to scrub the bran skin of the maize kernel and dislodge the germ from its cavity, with minimum reduction in the size of the broken fragments.

Control system comparison with other suppliers for maize milling machines.

Damper system comparison with others.

Pre-sales Consultation

We can design the processing technology according to your requirements.

Equipment Installation

Our professional technicians offer guidance in installation, commissioning of the machines, build up the workshop building and silos, and we can also help to reform the old workshop building as actual condation.

Training

Our professional technicians provide training workers of customers' factories, which is helpful to guarantee the normal operation of the equipment and reduce its downtime. In this way, the quality of finished products will be guaranteed.

Fixing and Maintenance

Our professional technical team can help solve any problem that occurs in a customer's flour production efficiently. We can do regular examinations of the equipment and offer you guidance on the equipment operation if you need it. Our staff in the Lusaka Office can go to see your site and machines directly and give some advice face to face.

Spare Parts Supply

Normally we will send you some wearing parts available for the one-year operation of the equipment in our first order. When you are in need of new spare parts in the future, we can send them directly from the Lusaka/Zambia Office time where have put a big storage room and deliver door to door.

1. The head office of Shijiazhuang Hongdefa Machinery Co., Ltd is located in the Wumashan industrial area, Zanhuang County, Shijiazhuang City is a 4-hour drive from Beijing. We are a professional factory and exporter combo for maize mill machines and wheat flour milling machines since 1982.

Hongdefa has approximately 120 workers, a manufacturing factory of 50000 square meters, 5000 square meters of production workshop, 6000 square meters of warehouses, 1000 square meters of office space

2. Advanced Processing Equipment

China and Australia and European Wheat Flour Mill Technology

China and South Africa Maize Mill Technology

3. Professional engineer team and sales team.

Our engineering team has more than 30 qualified engineers, all of them have more than 15 years of installation and designing experience in the flour mill field.

Our sales managers have more than 10 years of sales experience and have been to more than 20 countries to visit clients and build overseas offices.

4. Lifelong overseas services

we built our branch offices in Lusaka, Zambia, Addis Ababa, Ethiopia, Kampala, Uganda, Syndey, Australia, and we have agents from Brazil and Kenya.

5. Certification

Our maize milling plants all passed SGS, ISO, BV, CE, PVOC, COC, and SONCAP certificates.

Related Keywords