Hongdefa Hotsale Maize Flour Machine Grain Processing Line

-

$43500.00≥1 set

- Min. Order:

- 1 set

- Min. Order:

- 1 set

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

Product Description

Product Description

The 30T/24H Maize Mill Machine, we install in Zambia Angola Tanzania South Africa Kenya Malawi DR Congo Mozambique Zimbabwe Uganda Nigeria Ethiopia Ghana etc.

(1). Workshop Size: Length: 30M Width: 8M Height: 6M

(2). Power: Electricity 220V/380V/440V 3phase 50Hz/60Hz 100KVA

(3). Machine Material: Pipe in flour milling section is stainless steel, and moisture bin is stainless steel

(4). Final products: Maize flour grits/maize flour meal/maize flour

(5). By-product: Animal feed

(6). Successful Projects: Zambia Kenya Malawi Zimbabwe Angola etc. running our maize mill machine plants

(2). Power: Electricity 220V/380V/440V 3phase 50Hz/60Hz 100KVA

(3). Machine Material: Pipe in flour milling section is stainless steel, and moisture bin is stainless steel

(4). Final products: Maize flour grits/maize flour meal/maize flour

(5). By-product: Animal feed

(6). Successful Projects: Zambia Kenya Malawi Zimbabwe Angola etc. running our maize mill machine plants

Product Details

This design have following advantage:

1. Double layer stainless steel damper, 3 times lifetime than normal material damper.

2. Japan technology degerminator will remove bran and germ out to make sure the final products pure and fine.

3. Pneumatic roller mills, European standard machine with automatic running

4. Stainless steel pipes in flour system, 3 times lifetime than galvanized steel pipes.

5. Automatic touch screen control system, high technology and easy operate.

6. Auto packing system for option part for your choice

7. Impulse dust filter can make sure the whole workshop clean

2. Japan technology degerminator will remove bran and germ out to make sure the final products pure and fine.

3. Pneumatic roller mills, European standard machine with automatic running

4. Stainless steel pipes in flour system, 3 times lifetime than galvanized steel pipes.

5. Automatic touch screen control system, high technology and easy operate.

6. Auto packing system for option part for your choice

7. Impulse dust filter can make sure the whole workshop clean

Raw maize -- Cleaning Section -- Conditioning -- Degerminating -- Milling,

Sifting syetem -- Packing and Controlling system.

Cleaning, Conditioning System, Degerminating:

Damper: Two layers stainless steel damper, anty rusting and long life use.

Degerminator with Japan Technology and South Africa Experience, which is designed to scrub the bran skin from the maize Kernel and to dislodge the germ from its cavity, with the minimum reduction in size of the broken fragments

Damper: Two layers stainless steel damper, anty rusting and long life use.

Degerminator with Japan Technology and South Africa Experience, which is designed to scrub the bran skin from the maize Kernel and to dislodge the germ from its cavity, with the minimum reduction in size of the broken fragments

Automatic packing system in the wheat flour milling line:

It has different packing weight: 10kg 12.5kg 20kg 25kg and 50kg

1) Online auto cumulative weight

2) High-precision on-line flow control;

3) Frequency (batch) weight control;

4) With MODBUS communication interface with computer networking, computer centralized management control;

5) According to customer needs, can have the print function.

6) Feeding and support is stainless steel

1) Online auto cumulative weight

2) High-precision on-line flow control;

3) Frequency (batch) weight control;

4) With MODBUS communication interface with computer networking, computer centralized management control;

5) According to customer needs, can have the print function.

6) Feeding and support is stainless steel

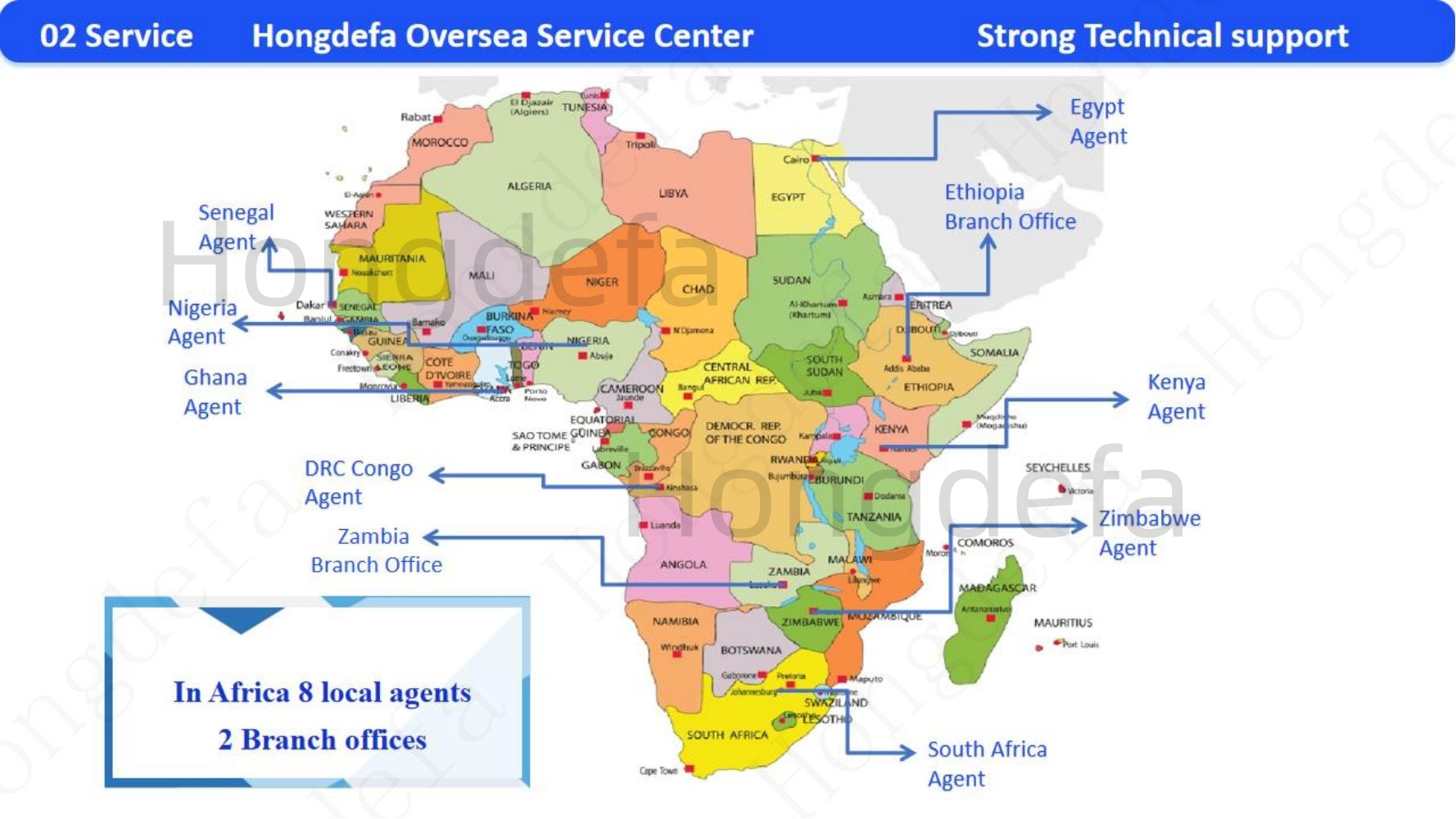

Sales And Service Network

Every year Hongdefa aftersales department do after-sales service for clients

Hongdefa have professional aftersales department to provide best aftersales service.

We are committed to ensuring client satisfaction while providing efficient and professional after-sales support.

Our team’s after-sales service scope includes but is not limited to:

We are committed to ensuring client satisfaction while providing efficient and professional after-sales support.

Our team’s after-sales service scope includes but is not limited to:

1) Answer questions about machine use and operation.

2) Provide clients with machine repair and maintenance recommendations.

3) Assist with machine breakdown and technical issues.

4) Relevant accessories and spare parts are available.

2) Provide clients with machine repair and maintenance recommendations.

3) Assist with machine breakdown and technical issues.

4) Relevant accessories and spare parts are available.

Hongdefa have branch offices in Africa: Lusaka/Zambia, Addis Ababa/Ethiopia

There we have staff and engineers. Our technicians can go directly to your workshop to investigate the site and design maize flour milling machine according to your workshop design.

We can provide you with 24-hour after-sales service.

When there is a problem with your maize mill machine, our engineers can help you solve it.

Hongdefa Factory

Hongdefa factory is worth visiting for every client

When you visit Hongdefa Factory, you can see the running machine with your own eyes and personally check the quality of maize meal, maize flour, maize grits, ect. We can show you all the single machines one by one and help you learn more information about each machine.

Successful Project

Our installed maize mill machine projects all over the world:

We are a professional factory with over 30 years of experience in producing 5t-500t/24h maize/corn mill machines.

Capacity | Country | |||

500T maize mill machine | South Africa(3 sets) Zimbabwe | |||

300T maize mill machine | Zimbabwe | |||

250T maize mill machine | Angola Zambia Kenya | |||

150T maize mill machine | Kenya Zambia Nigeria Malawi | |||

120T maize mill machine | Zimbabwe Malawi Swaziland | |||

100T maize mill machine | Kenya Zambia South Africa Nigeria Zimbabwe Mozambique Ethiopia | |||

70T maize mill machine | Malawi Zambia Kenya DR Congo Namibia Zimbabwe Thailand | |||

50T Maize mill machine | Uganda Zambia Kenya Malawi South Africa South Sudan Angola Ethiopia Cameroon Argentina DR Congo Namibia Zimbabwe Tanzania Nigeria Mozambique Venezuela Rwanda | |||

30T maize mill machine | Zambia Kenya Tanzania Uganda Rwanda Ghana Benin Nigeria Angola Malawi Namibia Mozambique Lesotho Zimbabwe South Africa Sri Lanka Vietnam Angola DR Congo Ethiopia Ecuador | |||

20T maize mill machine | Zambia Kenya Tanzania Uganda Rwanda Ghana Benin Nigeria Angola Malawi Namibia Mozambique Lesotho Zimbabwe South Africa DR Congo | |||

18T maize mill machine | Kenya Zimbabwe | |||

10T maize mill machine | Brundi Mali Burkina faso Togo Zambia Kenya Tanzania Uganda Rwanda Ghana Benin Nigeria Angola Malawi Namibia Mozambique Lesotho Zimbabwe South Africa | |||

5T maize mill machine | Brundi Mali Burkina faso Togo Zambia Kenya Tanzania Uganda Rwanda Ghana Somalia Benin Nigeria Angola Malawi Namibia Mozambique Lesotho Zimbabwe South Africa Zambia DR Congo |

Q1. Does the maize mill processing line can produce different kinds of maize meal, maize flour at the same time?

Yes, the maize mill processing line can produce different sizes of maize meal or maize flour at the same time at one production line.

Q2. Does the maize mill processing line run together with Generator?

Yes, the maize mill processing line can run together with Generator

Q3. Does the maize meal packing machine can pack different bags?

Yes, the packing machine can pack 1kg-5kg, 5kg-20kg, 12.5kg-25kg, 25-50kg

Q4. Does the maize mill line can process maize and wheat same time?

Yes, the maize mill processing line can produce different sizes of maize meal or maize flour at the same time at one production line.

Q2. Does the maize mill processing line run together with Generator?

Yes, the maize mill processing line can run together with Generator

Q3. Does the maize meal packing machine can pack different bags?

Yes, the packing machine can pack 1kg-5kg, 5kg-20kg, 12.5kg-25kg, 25-50kg

Q4. Does the maize mill line can process maize and wheat same time?

No, this is because maize and wheat have different Physical Characteristics, such as shape and hardness, all of them are different, and the final product's flour size is also different.

The cleaner, roller mill parameters, even the plansifter sieve is different.

As a professional manufacturer of maize/corn mill machine, we suggest that you do not process both maize and wheat at the same time.

Q5. Which country has installed the machine?

Kenya, Uganda, Tanzania, Zambia, Malawi, Namibia, Congo, South Africa, ect.

Q5. Which country has installed the machine?

Kenya, Uganda, Tanzania, Zambia, Malawi, Namibia, Congo, South Africa, ect.

Why Choose Hongdefa

Contact Details:

Please send your inquiry or leave message on Alibaba to talk with me directly.

Penny Cao

Penny Cao

I will provide you with professional suggestion based on your specific request and situation, and give you the best choice on your basic.

Related Keywords

Related Keywords

You May Also Like

You May Also Like