2T/H Grain Processing Machinery for Africa

-

$168000.001-1 set

-

$158000.002-2 set

-

$145000.00≥3 set

- Min. Order:

- 1 set

- Min. Order:

- 1 set

Your message must be between 20 to 2000 characters

Contact NowAutomatic 2T/H Grain Processing Machinery for Africa

| Product Name | 2t/h grain processing machinery |

| Workshop Size | 36m(L)*12m(W)*8m(H) |

| Power Consumption | 220kw |

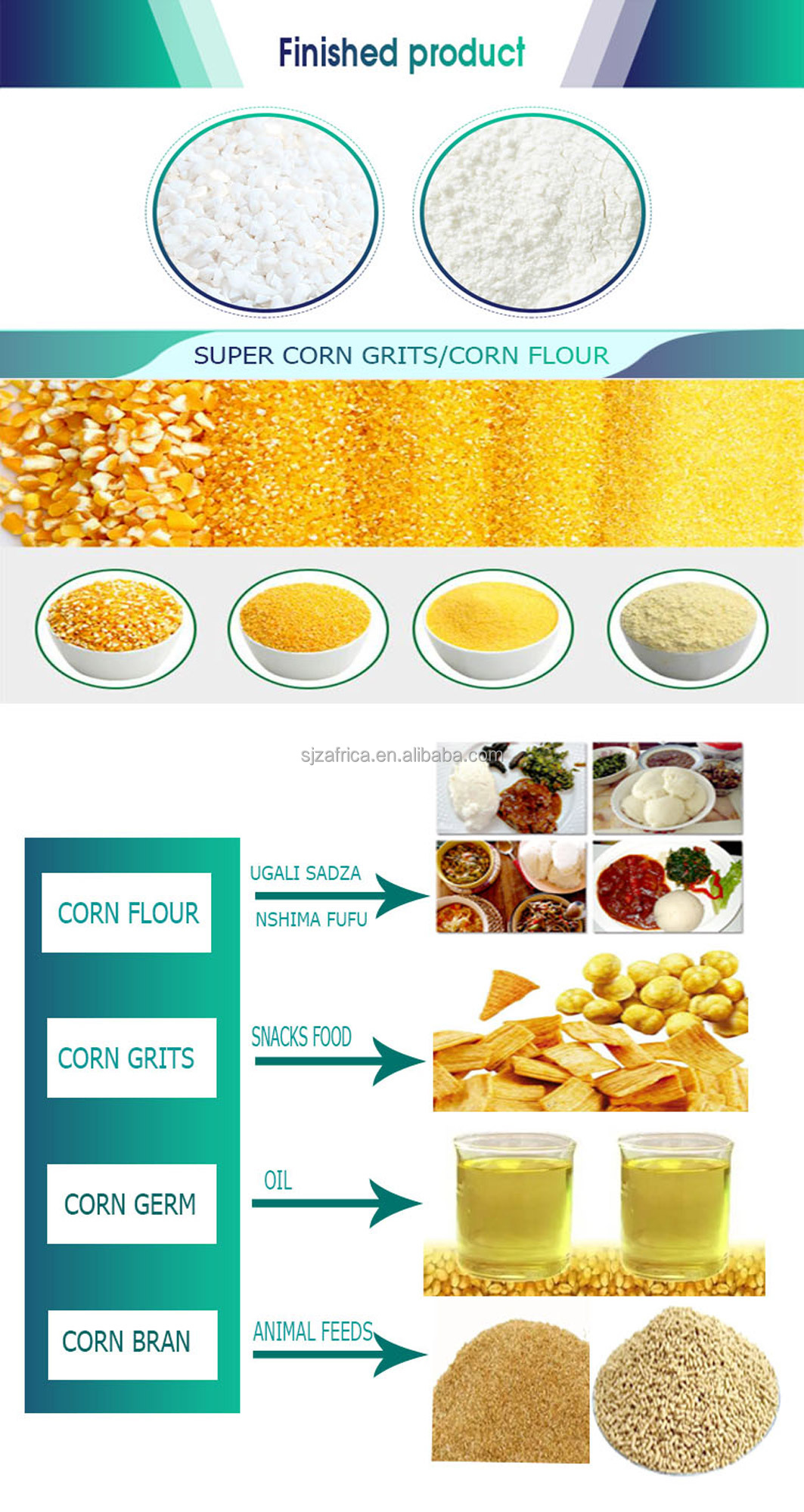

| Final Product | super white maize flour, maize meal,grits |

The 2 tons per hour grain processing machinery

The 2 tons per hour grain processing machinery installed in Cameroon.

One of our 2 tons per hour grain processing machinery

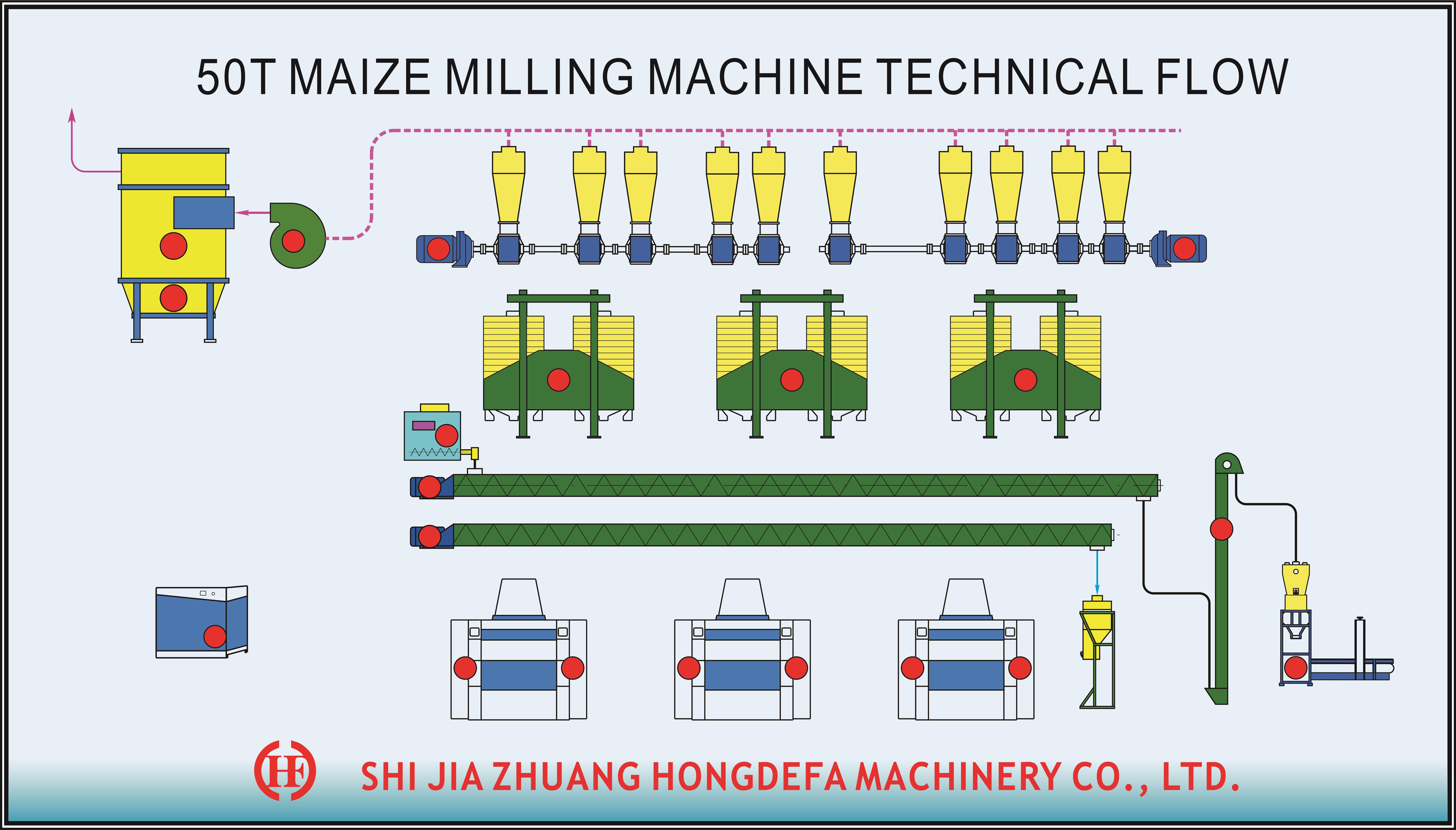

What is the technique flow for our grain processing machinery

1. Input maize --maize cleaner--maize moisture dampener --degerminator--roller mill--plansifter-super maize meal/special maize meal/maize grits--packing

What is the Specification of our grain processing machinery?

1. The control system: Control panel control or PLC control

2. Pipe in milling section is stainless steel

3. Auto-roller mill and plansifter

4. Japan Degerminator technology - To get super white maize meal

5. European Condition dampener -Stainless steel

Super white maize meal,special maize meal,maize grits,germ and bran,maize samp and rice etc.

It can be adjust according to local your market depending on your requirement.

Maize milling plant Final Products: Super maize meal/specail maize meal/maize grits/fine maize flour/maize bran and germ.

Our advantage as below:

A. Dergerminator

Our Degerminator with Japan technology, is designed to ‘scrub’ the bran skin from the maize kernel and to dislodge the germ from its cavity, with the minimum reduction in size of the broken fragments.

B. Roller Mill

1)The partitioned paneling and swing-out feed module guarantee ideal access to the feeding and grinding rolls. This makes residue-free cleaning possible.

2) a pulse generator automatically adjusts the feed material at the entrance door

3) bearing SKF

4)Sensor: Omron

C. Touch Screen Control/ PLC Automatic Control

D. Stainless Steel Pipes

Hongdefa 2T/H grain processing machinery flow is from cleaning to degerminating to milling to sifting to packing.

First,the maize enters the cleaning section, have gravity classification stoner remove the stone, then through the moisture damper is an important equipment to control the water content of the grain during in flour mills, stainless steel Bi-directional screw, prevent free water, an intensive intermixing. Next use degerminator (Japan technology ) to peeling, Then enter the milling section and sifting the flour, produce the produce super white flour, fine meal, bran, germ, etc which according to client requirements and needs. Finally, use the autoweighing &packing scale packing products.

Our advantages of Grain processing machinery

1. It's a complete line of cleaning, degerminating, milling, sifting, packing, and control system.

2. This line use " Japan technology" degerminator, which can remove germ and bran purely, can produce "super white" maize flour with low fat and without any black point.

3. In the double bin sifter, we will give you different hole sizes of mesh screens, to get the different sizes of final products.

4. The control system is the Touch Screen smart control system. it is more convenient to control all the machines working.

5. Double layer moisture dampener

6. Japan technology Degerminator - super white maize meal

7. Pipes in flour system: stainess steel

8. PLC computer control

9. Lifetime service: More clients earn money and order machines from our factory after one or two years.

10. Branch office all over of Africa,direct supply spare parts with good price

11. One year

ar spare parts for free ,load together with machines to delivery.

ar spare parts for free ,load together with machines to delivery.

| Product Name | different capacity of grain processing machinery |

| Final Product | Breakfast meal, roller meal, germ and bran |

| Flour Extraction | Adjustable, depending on different clients' requirements |

| Material | The pipes in the milling section are stainless steel, and the moisture bin is stainless steel |

| Main machine | Japan technology degerminator, European standard Pneumatic roller mill, Plansifters |

| Packing machine | Auto weighing& packaging machine |

| Control system | PLC control system |

| Certificate | CE, BV, SGS,PVOC,COC, SONCAP,ISO |

| Power | Electricity 380V/440V 3phase 50Hz/60Hz |

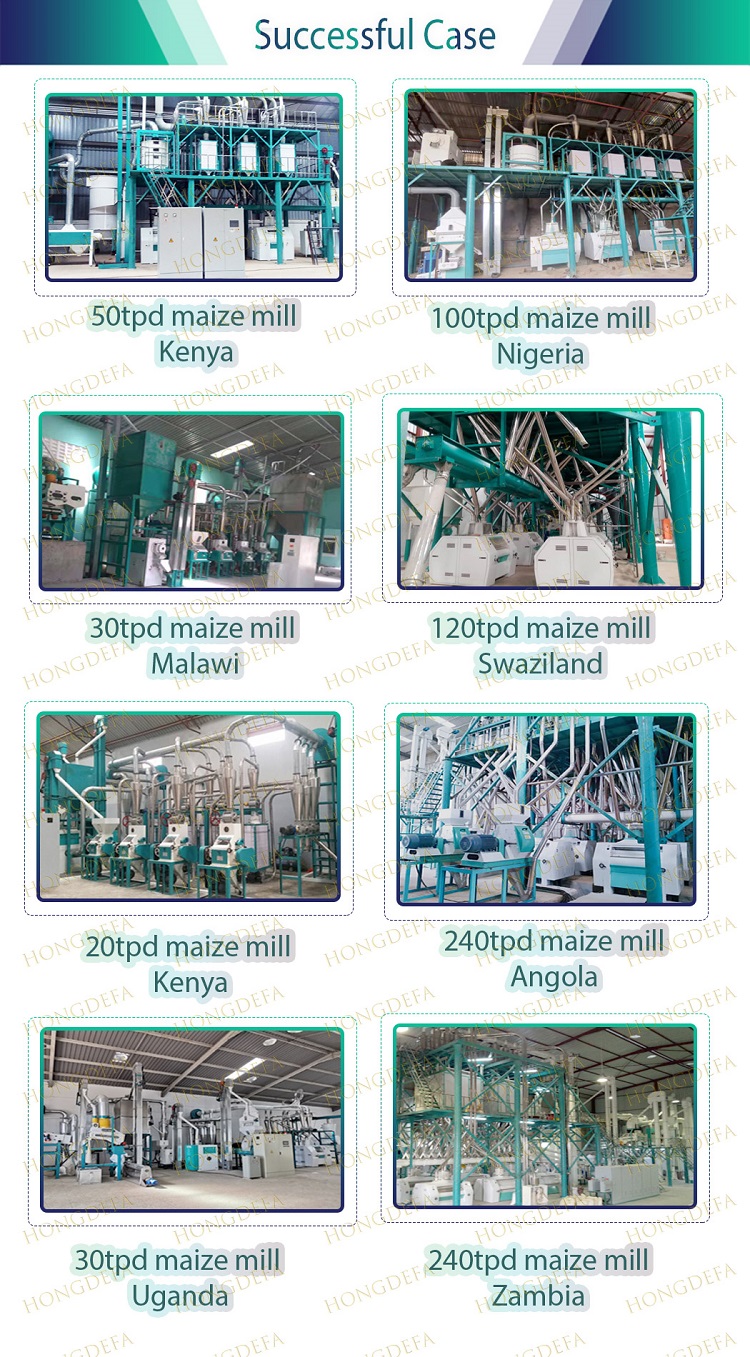

| Project | Kitwe/Zambia; Windhoek/Namibia; Lagos/Nigeria; Nairobi/Kenya running maize mill plant |

All maize milling machines are configured with the most suitable equipment according to the production line,

Including pneumatic mill, plan sifter, degerminater,vibrating cleaning sifter, stone remover and auto dampener. etc.

Provide the most perfect solution with the most advanced configuration, the highest quality and the lowest consumption.

Our projects are all over the world, such as in Zambia, Uganda, Ethiopia, Angola, South Africa, Malawi, Zimbabwe, Kenya, Nigeria, Congo, Cameroon, Mozambique, Namibia, Egypt, Pakistan, India, Thailand, Argentina, Brazil,Peru, etc.

All our machinery are high quality and have passed the certification of ISO, CE, BV, SGS and COC.

Our factory

The head office of Shijiazhuang Hongdefa Machinery Co.,Ltd is located in Wumashan industrial area, Zanhuang County,

Shijiazhuang City, 4hours driving From Beijing.

Hongdefa has approximately 120 workers, a manufacturing factory 50000 square meters, and 5000 square meters of

production workshop, 6000 square meters warehouses, 1000 square meters of office space.

Shijiazhuang Hongdefa Machinery Co.,Ltd is a professional manufacturer of wheat flour mill and maize mill,provide

high quality machine from 500kg/h to 50ton/h with different design according to our client needs,with European technology,

South Africa maize process,China wheat process, roll out unique and innovative wheat flour mill and maize milling machine.

FAQ:

A: Advanced pneumatic roller mills, The partitioned paneling and swing-out feed module guarantee ideal access to the feeding and grinding rolls. This makes residue-free cleaning possible.

And the pulse generator can automatically adjust the feed at the entrance, saving time and effort

A: maize degerminator is applicable for taking the germ and bran out of the maize, at the same time polishing the maize/maize grits, get pure white /yellow maize meal, maize grits, maize samp, and is characteristic of the high volume of production, compact structure, and convenient maintenance, thus making it an ideal equipment for maize processing in the modern age.

3. Q: How to put the HDF GRIN EXPER into my existing workshop?

A: We have the most professional engineering team to design according to your actual plant size the most suitable line and meet clients' demand

A: We can design the production line according to the final product required by the customer, and produce flour and grits at the same time through the technological process of different configurations.

Related Keywords