cooper mineral used Horizontal centrifugal mining slurry pump, mining pump

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

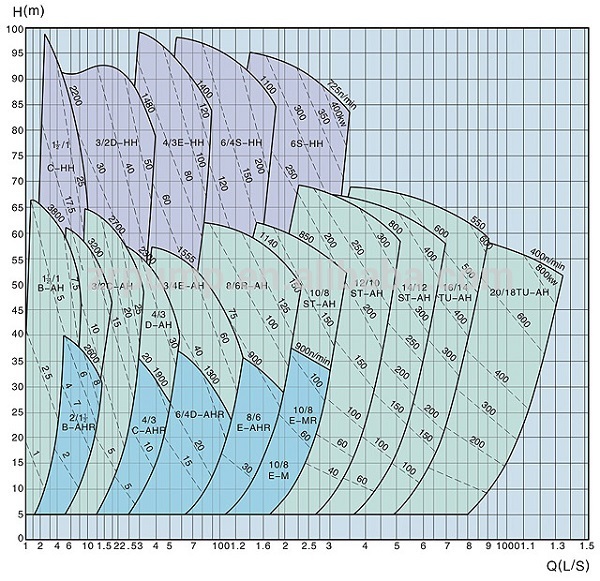

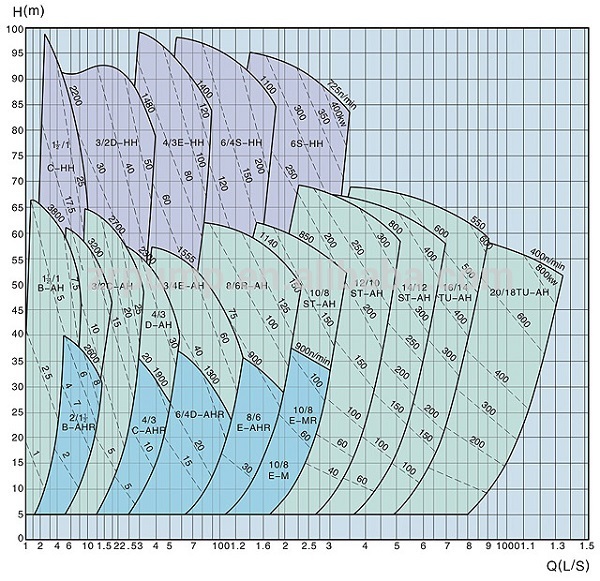

Shijiazhuang Industrial Pump co., ltd engaged in the different kinds of slurry pumps, such as mining slurry pump(horizontal model), sump pumps(vertical pump), sand pump(dredging pump), froth pump, newly product centrifugal fan, also with the requirement, the OEM pump can be provide. Size range (outlet):----- 1'' to 18'' (25 mm to 450 mm) Capacity:-------------- up to 22,000 gpm ( 5,000 m3/hr ) Head: -----------------up to 240 ft (73 m ) Pressure: --------------up to 300 psi (2,020 kPa)  For example: 6/4E-AH 6:------------Suction diameter (inch) 4:------------Discharge diameter (inch) E:-----------Base type AH:---------Heavy abrasive slurry pump

For example: 6/4E-AH 6:------------Suction diameter (inch) 4:------------Discharge diameter (inch) E:-----------Base type AH:---------Heavy abrasive slurry pump

For example: 6/4E-AH 6:------------Suction diameter (inch) 4:------------Discharge diameter (inch) E:-----------Base type AH:---------Heavy abrasive slurry pump

For example: 6/4E-AH 6:------------Suction diameter (inch) 4:------------Discharge diameter (inch) E:-----------Base type AH:---------Heavy abrasive slurry pump

|

|

|

|

|

|

Related Keywords

Related Keywords