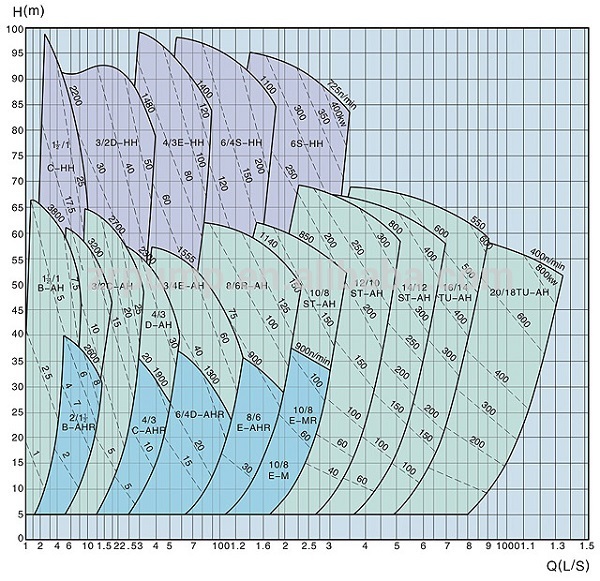

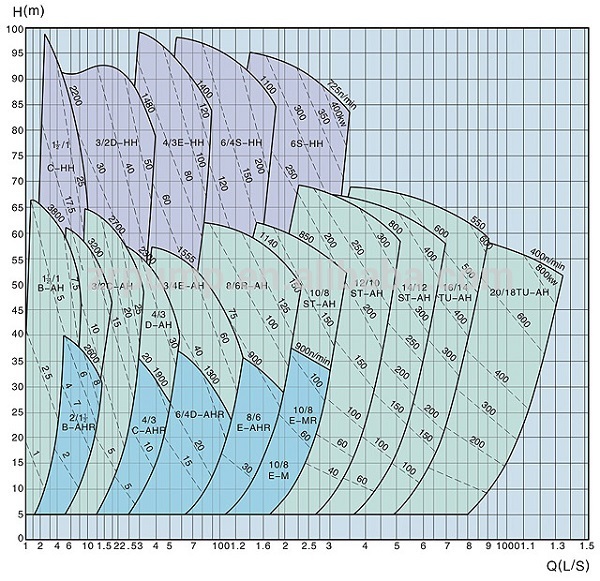

6/4 inches coal cooper and iron mineral centrifugal pump

- Delivery Time:

- 15 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

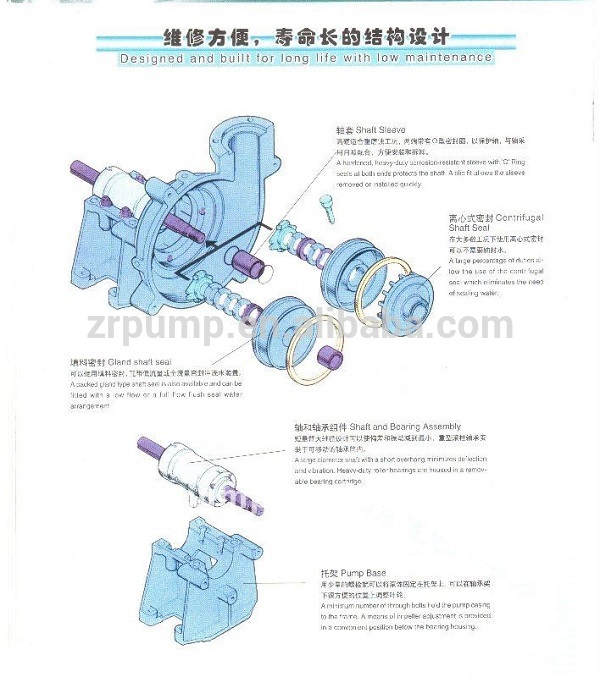

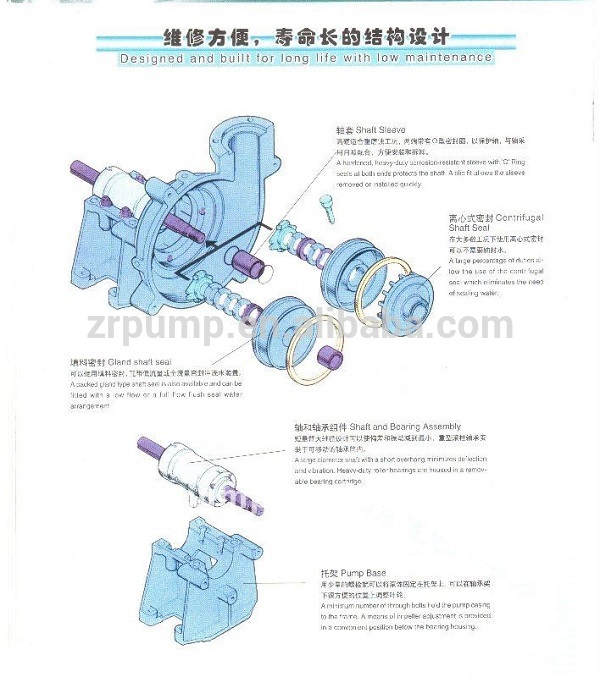

Shijiazhuang Industrial Pump co., ltd engaged in the different kinds of slurry pumps, such as mining slurry pump(horizontal model), sump pumps(vertical pump), sand pump(dredging pump), froth pump, newly product centrifugal fan, also with the requirement, the OEM pump can be provide. Slurry pump parts material: The mainly material of our slurry pumps are hi-chrome alloy(Cr18,Cr26,Cr27,and so on), stainless steel, gray iron, Wear parts High chrome alloy: A05, A07, A49, etc. Natural rubber: R08, R26, R33, R55, etc. Frame & Bearing Assembly types Types: B, C, D, E, F, R, X, ST, T, TU, CC, DD, EE, FF, etc. OEM part With the special request of client, we also can provide the slurry pump OEM parts based on the drawing or samples.

|

|

|

|

|

|

Related Keywords

Related Keywords