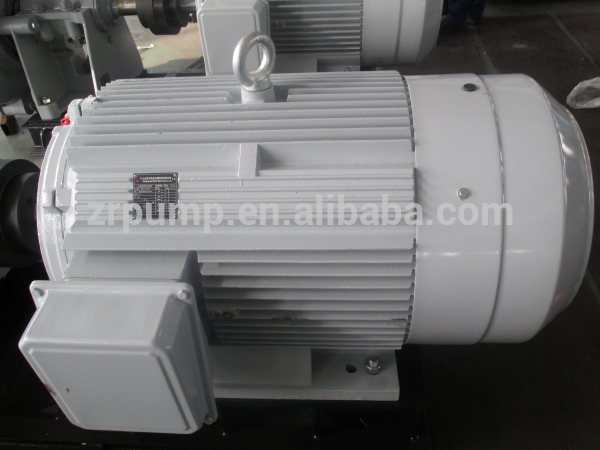

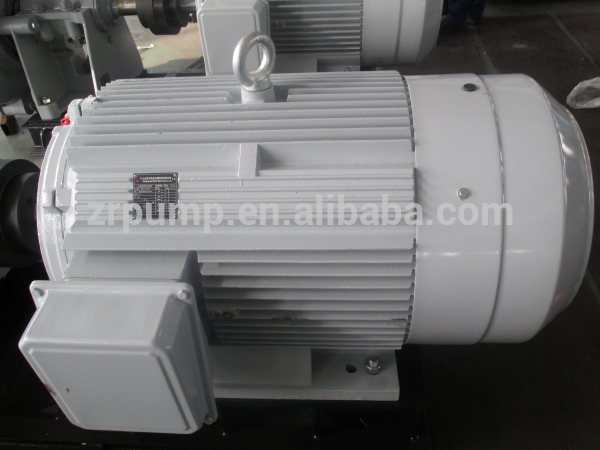

YE3 Series heavy duty electric motor for pumps

- Delivery Time:

- 10 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China (Mainland) |

|---|

Product Description

Product Description

electric motor for pumps Ac motor,Asychronous motor,Electric motor,Induction Motor. 3) Rated voltage: 380/660v 4) Frequency: 50Hz, 60Hz 5) Protection class: IP54 6) Insulation class: B,or F 7) Materials: cast iron(63-355), aluminum (FRAME 63-160) 8) EFF: EFF3, EFF2, EFF1 9) Poles: 2, 4, 6, 8, 10) Cooling method: IC411 (total-enclosed fan-cooled type) 11) Mounting types: IMB3, IMB5,IMB35 12) Operating mode: S1 13) Connection: "Y" type for 3kW and downwards, "D" type for 4kW and upwards 14) Ambient temperature: -15oC and 40oC 15) The altitude should be lower than 1,000m above the sea level 16) Relative humidity: not higher than 90% 17) Special motors can be designed according to customers' requirements BENIFITS TO CLIENT:

Reliable operation High efficiency Low noise Long life Power saving Slight vibration Try our best to meet customers' requirements, including voltage and frequency etc. It is newly designed in conformity with the relevant rules of IEC standards Special rotor balance for reduced vibration Warranty: 12 months from date of delivery. factory advantages Prompt Quotation. Competitive Price Guaranteed Quality Timely Delivery. 100% Tested. Sincere and Professional Service. Outstanding Finishing Surface. Strictly and Perfect Management is guaranteed for Production. Specialized in Manufacturing and Supplying a wide range of Electric Motors since year 2002. Have Rich Experience and Strong ability to Develop New Products. Have Ability to Design the Products Based on Your Original Samples Manufacturer process: Stamping of lamination Rotor die-casting Winding and inserting – both manual and semi-automatically Vacuum varnishing Machining shaft, housing, end shields, etc… Rotor balancing Painting – both wet paint and powder coating Motor assembly Packing Inspecting spare parts every processing 100% test after each process and final test before packing

Reliable operation High efficiency Low noise Long life Power saving Slight vibration Try our best to meet customers' requirements, including voltage and frequency etc. It is newly designed in conformity with the relevant rules of IEC standards Special rotor balance for reduced vibration Warranty: 12 months from date of delivery. factory advantages Prompt Quotation. Competitive Price Guaranteed Quality Timely Delivery. 100% Tested. Sincere and Professional Service. Outstanding Finishing Surface. Strictly and Perfect Management is guaranteed for Production. Specialized in Manufacturing and Supplying a wide range of Electric Motors since year 2002. Have Rich Experience and Strong ability to Develop New Products. Have Ability to Design the Products Based on Your Original Samples Manufacturer process: Stamping of lamination Rotor die-casting Winding and inserting – both manual and semi-automatically Vacuum varnishing Machining shaft, housing, end shields, etc… Rotor balancing Painting – both wet paint and powder coating Motor assembly Packing Inspecting spare parts every processing 100% test after each process and final test before packing