Crystallization of electromagnetic blender principle from IDEA

- Delivery Time:

- 4 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

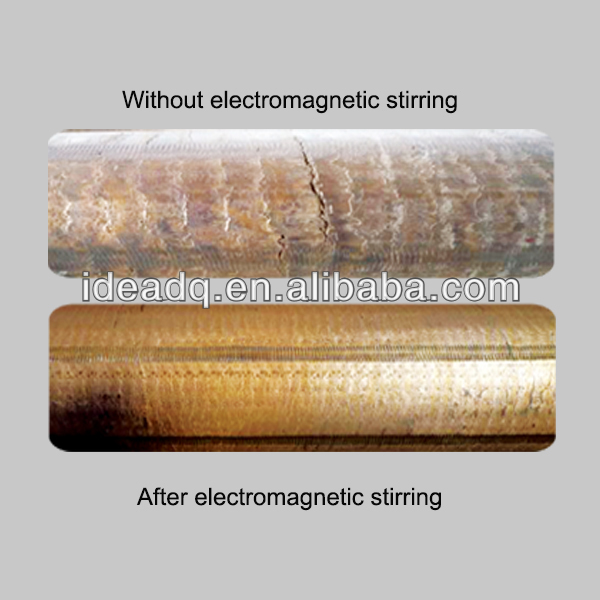

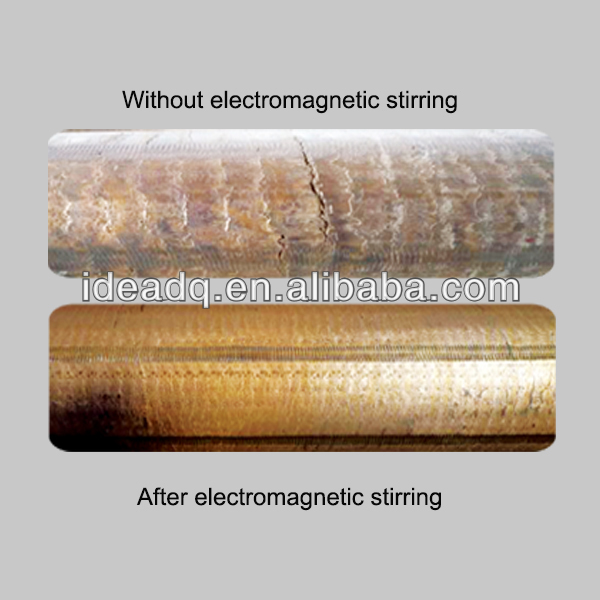

Application effect (1)Under the condition of existing technology, the technology of mold electromagnetic stirring on the chilling layer of slab small isometric with obvious effect (2) The center equiaxial crystal increase significantly, because columnar crystal narrow area, middle basically eliminate the crack. (3)Center shrinkage weakened degree. (4)Electromagnetic stirring in a certain degree of overheat help to eliminate the bad influence of high, similar to the low superheat casting. (5) Eliminate center segregation and loose, reduce that put an end to the core of the slab residual porosity, and improve the center of the slab segregation. Crystallization of electromagnetic blender principle is to use the change of the current to produce strong magnetic field, through the medium of the multilayer cut off, make continuous casting slab of internal metal melting liquid produce flow, through the state of the flow control to improve casting internal organization, component distribution, melting liquid dramatically and surface quality on the purpose. Because the role of the electromagnetic field with the contact, the distribution characteristics of uniform, especially suitable for high temperature and other special occasions. The production practice shows that the electromagnetic stirring improve columnar crystal, bypass, pinhole, increase the equiaxial crystal area, reduce the composition segregation, reduce or eliminate center loose and center of shrinkage effect is very obvious. Therefore, in a certain process condition, the choice of reasonable installation blender position, appropriate stir intensity and mixing way, control the flow of liquid form and melt flow speed, to improve the quality of casting billet have obvious function.  In ordinary casting process, Akira grew up in dendritic manner, when in steady rheological aspect is about 0.2, which is crystal form a continuous network skeleton, lose macro liquidity. If in the liquid metal from liquid to solid phase cooling process of strong mixing, can make ordinary casting when forming of the formation of the crystal to the branches were broken and reserve network skeleton scattered granular organization form, suspended in surplus liquid phase. The granular the branch of crystal microstructure, in in steady rheological aspect of 0.5-0.6 still has some of the rheological properties, thus forming process of conventional available such as casting, extrusion, and realize the forming of metal forging.

In ordinary casting process, Akira grew up in dendritic manner, when in steady rheological aspect is about 0.2, which is crystal form a continuous network skeleton, lose macro liquidity. If in the liquid metal from liquid to solid phase cooling process of strong mixing, can make ordinary casting when forming of the formation of the crystal to the branches were broken and reserve network skeleton scattered granular organization form, suspended in surplus liquid phase. The granular the branch of crystal microstructure, in in steady rheological aspect of 0.5-0.6 still has some of the rheological properties, thus forming process of conventional available such as casting, extrusion, and realize the forming of metal forging.

Product superiority (1)A high quality. For grain refinement, organization distribution even, and the body to reduce shrinkage crack down, hot tendency, except to pass shrinkage matrix, mechanical properties increased significantly. (2)The narrow solidification, so forming body size high precision, small machining allowance, net-shape forming. (3)Forming alloy scope. The ferroalloy have aluminum, magnesium, zinc, tin, copper, nickel alloy with; Iron base alloy have stainless steel, low alloy steel, etc. (4) Manufacturing metal matrix composites. Use of semi-solid metal high viscosity, make the density difference, solid solution for small metal alloy, also can effectively make different materials mixed, make new composite materials.

Product superiority (1)A high quality. For grain refinement, organization distribution even, and the body to reduce shrinkage crack down, hot tendency, except to pass shrinkage matrix, mechanical properties increased significantly. (2)The narrow solidification, so forming body size high precision, small machining allowance, net-shape forming. (3)Forming alloy scope. The ferroalloy have aluminum, magnesium, zinc, tin, copper, nickel alloy with; Iron base alloy have stainless steel, low alloy steel, etc. (4) Manufacturing metal matrix composites. Use of semi-solid metal high viscosity, make the density difference, solid solution for small metal alloy, also can effectively make different materials mixed, make new composite materials.

In ordinary casting process, Akira grew up in dendritic manner, when in steady rheological aspect is about 0.2, which is crystal form a continuous network skeleton, lose macro liquidity. If in the liquid metal from liquid to solid phase cooling process of strong mixing, can make ordinary casting when forming of the formation of the crystal to the branches were broken and reserve network skeleton scattered granular organization form, suspended in surplus liquid phase. The granular the branch of crystal microstructure, in in steady rheological aspect of 0.5-0.6 still has some of the rheological properties, thus forming process of conventional available such as casting, extrusion, and realize the forming of metal forging.

In ordinary casting process, Akira grew up in dendritic manner, when in steady rheological aspect is about 0.2, which is crystal form a continuous network skeleton, lose macro liquidity. If in the liquid metal from liquid to solid phase cooling process of strong mixing, can make ordinary casting when forming of the formation of the crystal to the branches were broken and reserve network skeleton scattered granular organization form, suspended in surplus liquid phase. The granular the branch of crystal microstructure, in in steady rheological aspect of 0.5-0.6 still has some of the rheological properties, thus forming process of conventional available such as casting, extrusion, and realize the forming of metal forging.

Product superiority (1)A high quality. For grain refinement, organization distribution even, and the body to reduce shrinkage crack down, hot tendency, except to pass shrinkage matrix, mechanical properties increased significantly. (2)The narrow solidification, so forming body size high precision, small machining allowance, net-shape forming. (3)Forming alloy scope. The ferroalloy have aluminum, magnesium, zinc, tin, copper, nickel alloy with; Iron base alloy have stainless steel, low alloy steel, etc. (4) Manufacturing metal matrix composites. Use of semi-solid metal high viscosity, make the density difference, solid solution for small metal alloy, also can effectively make different materials mixed, make new composite materials.

Product superiority (1)A high quality. For grain refinement, organization distribution even, and the body to reduce shrinkage crack down, hot tendency, except to pass shrinkage matrix, mechanical properties increased significantly. (2)The narrow solidification, so forming body size high precision, small machining allowance, net-shape forming. (3)Forming alloy scope. The ferroalloy have aluminum, magnesium, zinc, tin, copper, nickel alloy with; Iron base alloy have stainless steel, low alloy steel, etc. (4) Manufacturing metal matrix composites. Use of semi-solid metal high viscosity, make the density difference, solid solution for small metal alloy, also can effectively make different materials mixed, make new composite materials. Related Keywords

Related Keywords

You May Also Like

You May Also Like