All kinds of power frequency electromagnetic stirring alloy holding furnace

- Delivery Time:

- 4 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

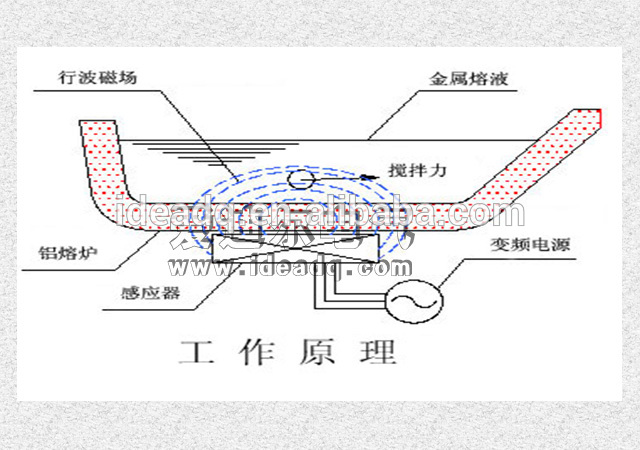

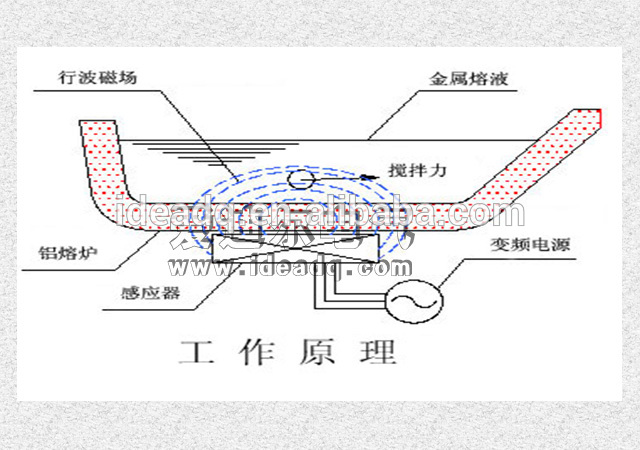

The principle of electromagnetic stirring alloy holding furnace

Electromagnetic stirring alloy holding furnace is series products of our company for small alloy melting pot research and development production, have furnace heat preservation box of electromagnetic stirring function itself, heat preservation temperature up to 1300 degrees Celsius, melting pot of up to 1500 kg. Equipment function characteristics:

Equipment function characteristics:

1)Electromagnetic stirring and the solution without physical contact, do not pollute the aluminum solution, this in smelting the alloy with high purity metal has important significance.

2)Can effectively solve the problem of uniformity of alloy composition, In some cases to reach the effect the workers won’t reach. 3)Don't stir destroy the oxide layer, also don't need to open the oven door, so can reduce the oxidation slag, reduce the burning loss rate. 4)Reduce the workers labor intensity.

5)By changing the direction and strength of the magnetic field, can effectively regulate solution agitation reverse and stirring intensity. 6)Using resistance heating efficiency, PID automatic temperature control, can effectively save the input power to reduce costs. 7)One-time investment, use cost is low, save energy, enhance productivity. 8)Operation and maintenance is simple and convenient. 9)Workers can easy to master, operation is simple and convenient

The process effect of product application:

Because of the electromagnetic stirring speed heat release, changing the flow of the melt, can effectively inhibit the growth of the columnar crystal, make the grain to axiation. Change of precipitation phase morphology at the same time reduce macrosegregation and microsegregation, increase the crystal nucleus, grain size, uniform temperature, let the solidifying in larger volume range to refine grain is enhanced at the same time, this in the crystallization process of mixing more meaningful. By electromagnetic stirring, the chemical composition of the whole furnace melt relative deviation can be controlled within 10%.

Can greatly shorten the melting time

Electromagnetic stirring without opening the oven door, reduce the heat loss, improved the burner combustion efficiency. A lot of application data indicate, in general, electromagnetic stirring can shorten the melting time about for no more than 20% of the electromagnetic stirring, can be reduced by 10% - 15% of fuel consumption, productivity can be increased by 15% - 30%.

Because of the electromagnetic stirring, can make in a short time solution to the technological requirement, and stir fully, can significantly reduce molten metal drops in the slag layer inside the package, shorten the solution exposed to the air time, so as to improve the recovery efficiency of metal, slag reduction is roughly around 15% - 30%.

Greatly shorten the uniform temperature and composition of the time, and improve overall uniformity.

Electromagnetic stirring alloy holding furnace is series products of our company for small alloy melting pot research and development production, have furnace heat preservation box of electromagnetic stirring function itself, heat preservation temperature up to 1300 degrees Celsius, melting pot of up to 1500 kg.

Equipment function characteristics:

Equipment function characteristics:1)Electromagnetic stirring and the solution without physical contact, do not pollute the aluminum solution, this in smelting the alloy with high purity metal has important significance.

2)Can effectively solve the problem of uniformity of alloy composition, In some cases to reach the effect the workers won’t reach. 3)Don't stir destroy the oxide layer, also don't need to open the oven door, so can reduce the oxidation slag, reduce the burning loss rate. 4)Reduce the workers labor intensity.

5)By changing the direction and strength of the magnetic field, can effectively regulate solution agitation reverse and stirring intensity. 6)Using resistance heating efficiency, PID automatic temperature control, can effectively save the input power to reduce costs. 7)One-time investment, use cost is low, save energy, enhance productivity. 8)Operation and maintenance is simple and convenient. 9)Workers can easy to master, operation is simple and convenient

The process effect of product application:

Because of the electromagnetic stirring speed heat release, changing the flow of the melt, can effectively inhibit the growth of the columnar crystal, make the grain to axiation. Change of precipitation phase morphology at the same time reduce macrosegregation and microsegregation, increase the crystal nucleus, grain size, uniform temperature, let the solidifying in larger volume range to refine grain is enhanced at the same time, this in the crystallization process of mixing more meaningful. By electromagnetic stirring, the chemical composition of the whole furnace melt relative deviation can be controlled within 10%.

Can greatly shorten the melting time

Electromagnetic stirring without opening the oven door, reduce the heat loss, improved the burner combustion efficiency. A lot of application data indicate, in general, electromagnetic stirring can shorten the melting time about for no more than 20% of the electromagnetic stirring, can be reduced by 10% - 15% of fuel consumption, productivity can be increased by 15% - 30%.

Because of the electromagnetic stirring, can make in a short time solution to the technological requirement, and stir fully, can significantly reduce molten metal drops in the slag layer inside the package, shorten the solution exposed to the air time, so as to improve the recovery efficiency of metal, slag reduction is roughly around 15% - 30%.

Greatly shorten the uniform temperature and composition of the time, and improve overall uniformity.

Related Keywords

Related Keywords

You May Also Like

You May Also Like