Design of electromagnetic pump

- Delivery Time:

- 4 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

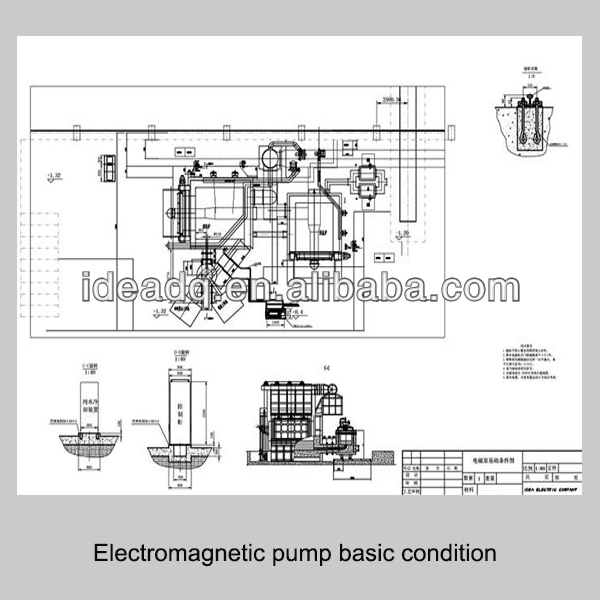

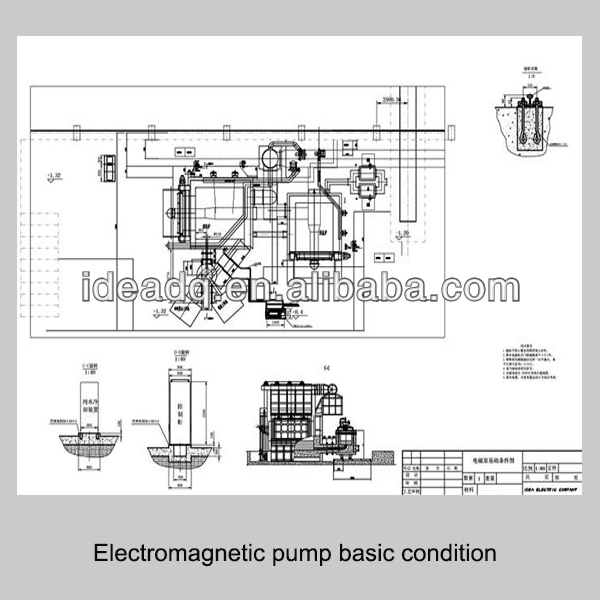

Aluminium electromagnetic pump is based on the principle of linear motor. When the pump body work by special coil structure in the traveling wave magnetic field generated inside, magnetic field and the internal melting liquid interact to produce magnetic thrust, electromagnetic thrust high temperature melting furnace will take high speed to the circular liquid material well inner cavity, and on the material in high speed whirlpool well formed, whirlpool will be broken material involved, through the back into the melting pot bottom tube. Change the power supply voltage and current phase, can change the size of the electromagnetic thrust and direction.  Electromagnetic pump basic condition:

Electromagnetic pump basic condition:

Electromagnetic pump installation

Electromagnetic pump principle Electromagnetic pump is the use of magnetic field and current in the conductive fluid interaction, make the fluid by the electromagnetic force and pressure gradient, a device to push the fluid motion. Mostly used for pumping liquid metal in the practical, so is also called the liquid metal electromagnetic pump. The role of electromagnetic pump is in the closed pipeline system to transmission of liquid metal, or other conductible liquid. In this sense, electromagnetic pump is familiar with rotating impeller drive equipment, the difference is the force generated in a different way. Drivers can use the right hand rule, when current flows through a conductor, will produce an induced magnetic field with metal solution produce induced current, induced current and magnetic field produce electromagnetic force, The force is the motive force of the molten metal movement, this force is not generated by mechanical components, and the metal solution not contact is the most important feature of electromagnetic pump. Electromagnetic pump no mechanical moving parts, simple structure, good sealing, reliable running and don't need a shaft seal, therefore in the chemical industry, printing industry, used for conveying some toxic heavy metals, such as mercury, lead, etc. Used in nuclear power and nuclear fusion device transmit the molten nonferrous metals (sodium or potassium, sodium, potassium alloys, lithium lead), more widely used in metallurgy transport molten nonferrous metal casting production. The flow rate can reach 13000 m/h, the Pressure can reach 1.5 MPa, temperature is 1200 °C.

Electromagnetic pump basic condition:

Electromagnetic pump basic condition:

Electromagnetic pump installation

Electromagnetic pump principle Electromagnetic pump is the use of magnetic field and current in the conductive fluid interaction, make the fluid by the electromagnetic force and pressure gradient, a device to push the fluid motion. Mostly used for pumping liquid metal in the practical, so is also called the liquid metal electromagnetic pump. The role of electromagnetic pump is in the closed pipeline system to transmission of liquid metal, or other conductible liquid. In this sense, electromagnetic pump is familiar with rotating impeller drive equipment, the difference is the force generated in a different way. Drivers can use the right hand rule, when current flows through a conductor, will produce an induced magnetic field with metal solution produce induced current, induced current and magnetic field produce electromagnetic force, The force is the motive force of the molten metal movement, this force is not generated by mechanical components, and the metal solution not contact is the most important feature of electromagnetic pump. Electromagnetic pump no mechanical moving parts, simple structure, good sealing, reliable running and don't need a shaft seal, therefore in the chemical industry, printing industry, used for conveying some toxic heavy metals, such as mercury, lead, etc. Used in nuclear power and nuclear fusion device transmit the molten nonferrous metals (sodium or potassium, sodium, potassium alloys, lithium lead), more widely used in metallurgy transport molten nonferrous metal casting production. The flow rate can reach 13000 m/h, the Pressure can reach 1.5 MPa, temperature is 1200 °C.

Related Keywords

Related Keywords

You May Also Like

You May Also Like