Design all kinds of semi-solid electromagnetic stirrer

- Delivery Time:

- 4 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

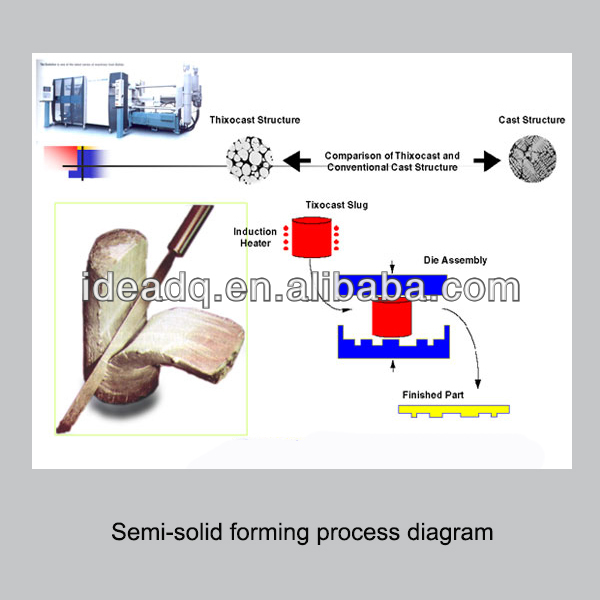

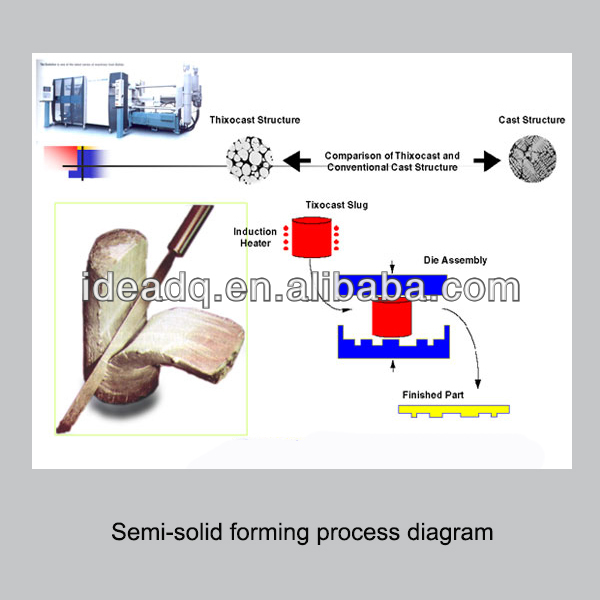

1, summarize Since 1971, D.B.Spencer and M.C.Flemingsthe who were from united States at the Massachusetts institute of technology, has created a new process of stir casting (stir cast), since to use the rotating double bucket mechanical mixing method produce the Srr15%pb rheological slurry, semi-solid metal (SSM) casting technology has experienced more than 20 years of research and development. Stir casting preparation of alloy commonly referred to as non dendritic structure or partially solidified casting alloys. Because adopting this technology’s product has the characteristics of high quality, high performance and high alloying, so it is of strong vitality. In addition to the application of military equipment, began mainly used for the key components of automotive, for example, for the automobile wheel hub, can improve performance, reduce weight, reduce scrap rate. Since then, gradually been used in other areas, produce the high-performance and near net shape parts. The molding machinery of semi-solid metal casting process has introduced. At present has developed to produce the semi-solid casting die casting machine from 600 tons to 2000 tons, forming parts can reach more than 7 kg in weight. At present, in the United States and Europe, the application of the technology is more widely. Semi-solid metal casting process is considered to be one of the most promising near net shape and a new materials preparation technology in the 21st century. 2,Technical principle In the ordinary course of casting, primary crystal grew up in dendritic manner, when solid rate around 0.2, dendritic crystal to form a continuous network skeleton, loss the macro liquidity. If get strong stirring when the liquid metal from liquid phase to solid phase in the process of cooling, make the casting is easy to form the branch crystal network skeleton in normal be broken and retains the dispersed particle morphology, suspended in the surplus liquid phase. This kind of granular non-dendrite microstructural, in steady rheological aspect in 0.5-0.6 still has certain rheology, which can use conventional forming process, such as die casting, extrusion, forging and metal forming. 3,Look into the distance Although the semisolid continuous casting technology haven't reached the level of large-scale industrial applications, but in the existing experiment research and small-scale production has showed a strong vitality. Comprehensive domestic and foreign relevant research it is not hard to see, semi-solid casting technology will has a bright application prospect in the following areas: (1) High alloy and difficult deformation materials’ forming High alloy and difficult deformation materials’ forming has always been a difficult problem in the field of material in processing. The semisolid continuous casting billet in the semi-solid temperature has similar to liquid molding directly forming’s advantage, for high alloy materials’ no segregation, no defects casting and the difficult deformation’s material’s forming find a feasible technical route. This research study, usually think which not for forging like white iron, high manganese steel, after made of semi-solid casting billet, in the semi-solid temperature can smoothly forming wall thickness 2 mm, length is 100 mm or more complex parts. Therefore, materials forming semi-solid casting in difficult deformation with the billet production have a brilliant future. (2)The develop of new generation of iron and steel materials Now all countries in the world is in super steel research, our country also has significant foundation program start” a new generation of iron and steel materials research”. A new generation of iron and steel materials requires high clean, ultrafine, ultra-high strength, at the same time also has the potential of large-scale application. To achieve this goal, Will need to use continuous casting technology has been using, while the existing continuous casting billet is common area of the columnar crystal, macrosegregation defects seriously, semi-solid casting billet grain size is small, macrosegregation advantage will no doubt be less for a new generation of iron and steel material blocking a worth exploring the technical route. (3) Composite mat and molding Composite materials science is a rookie, yet so far, the preparation of composite materials. The semisolid continuous casting in solving this problem will go a long way, it has been many test by a great number of experimental study. In a word, the semisolid continuous casting technology in high alloy material, difficult deformation, fine crystal homogenization steel material and new material of high bonus attached molding has unique technical advantages.  4,Semi-solid die casting technology and product advantages Technics predominance 1) Without any grain refining agent can obtain fine grain structure, eliminates the traditional rough casting of columnar crystals and dendrites. 2) Forming temperature is low (Such as aluminum alloy can reduce more than 1200 °C), can save energy. 3) Die longevity is longer. Solid and low temperature of semi-solid slurry forming shear stress, is smaller than traditional dendrite size three orders of magnitude, therefore, smooth filling, heat load is small, thermal fatigue strength degradation. 4) Reduce pollution and unsafe factors. When working it get rid of the high temperature liquid metal environment. 5) Resistance to deformation is small, use smaller force can achieve homogeneous processing, forming the difficult-to-machine materials is easily. 6) Solidification speed faster, productivity higher, the process cycle shorter. 7) Suitable for using computer aided design and manufacturing, enhance the automation of the production. Product superiority 1) A high quality. Due to the grain refinement, microstructure Distribution Homogenize, reduce body contraction, cracking tendency to decline, eliminated shrinkage tendency on the base, mechanical properties increase significantly. 2) Closed narrowing of solidification, so the molding body size precision is high, machining allowance is small, near-net forming. 3) Forming alloy is wide. Nonferrous alloy are aluminum, magnesium, zinc, tin, copper, nickel base alloy; Iron base alloys such as stainless steel, low alloy steel. 4) Manufacture of metal matrix composite materials. Use high viscosity of semi-solid metal, make the density difference, small solid solubility of metal alloys, also can effectively make mixing different materials, making a new composite materials.

4,Semi-solid die casting technology and product advantages Technics predominance 1) Without any grain refining agent can obtain fine grain structure, eliminates the traditional rough casting of columnar crystals and dendrites. 2) Forming temperature is low (Such as aluminum alloy can reduce more than 1200 °C), can save energy. 3) Die longevity is longer. Solid and low temperature of semi-solid slurry forming shear stress, is smaller than traditional dendrite size three orders of magnitude, therefore, smooth filling, heat load is small, thermal fatigue strength degradation. 4) Reduce pollution and unsafe factors. When working it get rid of the high temperature liquid metal environment. 5) Resistance to deformation is small, use smaller force can achieve homogeneous processing, forming the difficult-to-machine materials is easily. 6) Solidification speed faster, productivity higher, the process cycle shorter. 7) Suitable for using computer aided design and manufacturing, enhance the automation of the production. Product superiority 1) A high quality. Due to the grain refinement, microstructure Distribution Homogenize, reduce body contraction, cracking tendency to decline, eliminated shrinkage tendency on the base, mechanical properties increase significantly. 2) Closed narrowing of solidification, so the molding body size precision is high, machining allowance is small, near-net forming. 3) Forming alloy is wide. Nonferrous alloy are aluminum, magnesium, zinc, tin, copper, nickel base alloy; Iron base alloys such as stainless steel, low alloy steel. 4) Manufacture of metal matrix composite materials. Use high viscosity of semi-solid metal, make the density difference, small solid solubility of metal alloys, also can effectively make mixing different materials, making a new composite materials.

4,Semi-solid die casting technology and product advantages Technics predominance 1) Without any grain refining agent can obtain fine grain structure, eliminates the traditional rough casting of columnar crystals and dendrites. 2) Forming temperature is low (Such as aluminum alloy can reduce more than 1200 °C), can save energy. 3) Die longevity is longer. Solid and low temperature of semi-solid slurry forming shear stress, is smaller than traditional dendrite size three orders of magnitude, therefore, smooth filling, heat load is small, thermal fatigue strength degradation. 4) Reduce pollution and unsafe factors. When working it get rid of the high temperature liquid metal environment. 5) Resistance to deformation is small, use smaller force can achieve homogeneous processing, forming the difficult-to-machine materials is easily. 6) Solidification speed faster, productivity higher, the process cycle shorter. 7) Suitable for using computer aided design and manufacturing, enhance the automation of the production. Product superiority 1) A high quality. Due to the grain refinement, microstructure Distribution Homogenize, reduce body contraction, cracking tendency to decline, eliminated shrinkage tendency on the base, mechanical properties increase significantly. 2) Closed narrowing of solidification, so the molding body size precision is high, machining allowance is small, near-net forming. 3) Forming alloy is wide. Nonferrous alloy are aluminum, magnesium, zinc, tin, copper, nickel base alloy; Iron base alloys such as stainless steel, low alloy steel. 4) Manufacture of metal matrix composite materials. Use high viscosity of semi-solid metal, make the density difference, small solid solubility of metal alloys, also can effectively make mixing different materials, making a new composite materials.

4,Semi-solid die casting technology and product advantages Technics predominance 1) Without any grain refining agent can obtain fine grain structure, eliminates the traditional rough casting of columnar crystals and dendrites. 2) Forming temperature is low (Such as aluminum alloy can reduce more than 1200 °C), can save energy. 3) Die longevity is longer. Solid and low temperature of semi-solid slurry forming shear stress, is smaller than traditional dendrite size three orders of magnitude, therefore, smooth filling, heat load is small, thermal fatigue strength degradation. 4) Reduce pollution and unsafe factors. When working it get rid of the high temperature liquid metal environment. 5) Resistance to deformation is small, use smaller force can achieve homogeneous processing, forming the difficult-to-machine materials is easily. 6) Solidification speed faster, productivity higher, the process cycle shorter. 7) Suitable for using computer aided design and manufacturing, enhance the automation of the production. Product superiority 1) A high quality. Due to the grain refinement, microstructure Distribution Homogenize, reduce body contraction, cracking tendency to decline, eliminated shrinkage tendency on the base, mechanical properties increase significantly. 2) Closed narrowing of solidification, so the molding body size precision is high, machining allowance is small, near-net forming. 3) Forming alloy is wide. Nonferrous alloy are aluminum, magnesium, zinc, tin, copper, nickel base alloy; Iron base alloys such as stainless steel, low alloy steel. 4) Manufacture of metal matrix composite materials. Use high viscosity of semi-solid metal, make the density difference, small solid solubility of metal alloys, also can effectively make mixing different materials, making a new composite materials. Related Keywords

Related Keywords

You May Also Like

You May Also Like