The crystallization of semi-solid stirrer 2016

- Delivery Time:

- 4 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

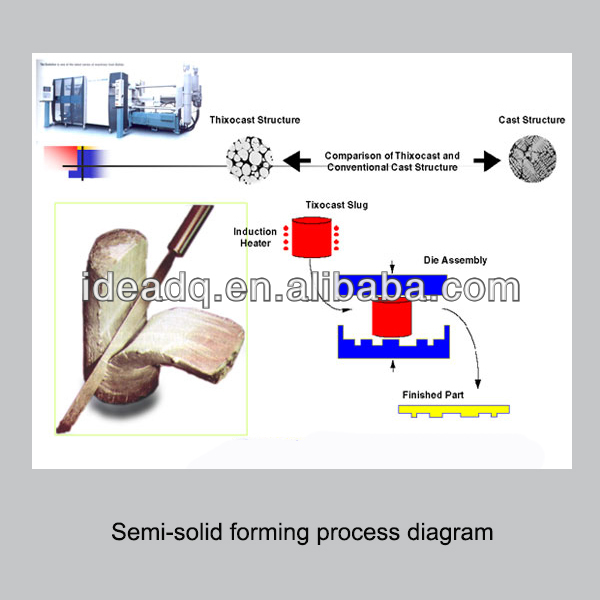

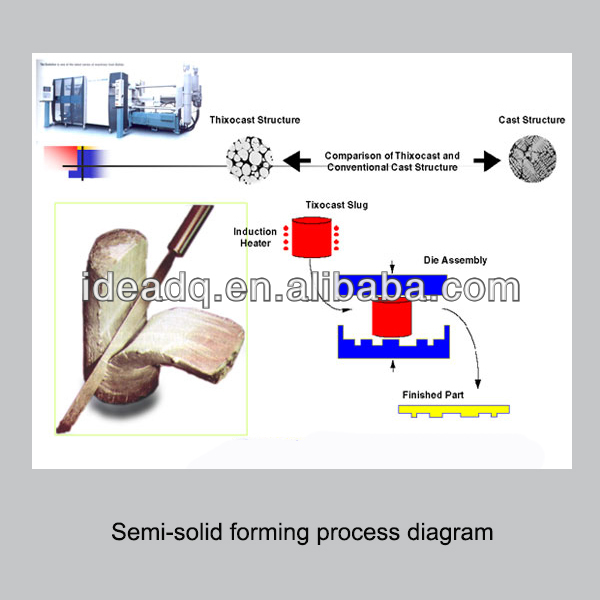

Summarize: Since 1971, the United States at the Massachusetts institute of technology D.B.S pencer and M.C.F lemings invented a stirring casting (stir cast) new process, with twin barrels of mechanical mixing method prepared for srr15 % pb rheological slurry, semisolid metal (SSM) casting technology has experienced more than 20 years of research and development. The alloy of stirring casting preparation commonly referred to as non-dendritic structure alloy or partially solidified casting alloys. Because of adopting the technology of the product has the characteristics of high quality, high performance and high alloying, So it is of strong vitality. In addition to the application of military equipment, began to focus on the key components for the automotive, such as, used for automobile wheel hub, can improve performance, reduce weight, reduce scrap rate. Since then, gradually been used in other areas, produce of high-performance and near net shape parts. Semi-solid metal casting molding machinery also launched. Now, has been developed to produce from 600 tons to 2000 tons semi-solid casting die casting machine, forming a weight can reach more than 7 kg. At present, in the United States and Europe, the process technology are more widely application. Semi-solid metal casting process is considered to be one of the most promising preparative technique of the near net shape and new material preparation in 21st century.  Outlook Although the semisolid continuous casting technology haven't reached the level of large-scale industrial application, But in the existing experimental research and small-scale production has shown a strong vitality. Synthesizing the relevant research both at home and abroad is not hard to see, semi-solid casting technology in the following areas has a bright application prospect: (1) High alloy and difficult deformation material forming High alloy materials and difficult deformation material forming has been a difficult problem in the field of material processing. The semisolid continuous casting billet in the semi-solid temperature has the similar advantage of the liquid molding directly, for high alloy material no segregation, no defects casting and difficult deformation material forming smoothly found a feasible technical route. The research team researches show that, usually think not of forging white iron and high manganese steel, After made of semi-solid casting billet, in the semi-solid temperature molding thickness 2 mm, a length of more than 100 mm complex parts. Therefore, the semisolid continuous casting in terms of difficult deformation material molding with billet production will have a brilliant future. (2) The development of a new generation steel and iron material Now all countries in the world in the super steel research, our country also has been started important basic planning project“A new generation of iron and steel materials research”. A new generation of iron and steel material requires high clean, ultrafine, ultra-high strength, at the same time also has the potential of large scale application. In order to achieve this goal, will need to adopt continuous casting technology to made blank, while the existing continuous casting billet are widespread columnar crystal area is big, the macro segregation seriously flawed. The semisolid continuous casting billet tiny grains, less of macrosegregation advantage will no doubt be less for a new generation of iron and steel material blocking a worth exploring the technical route. (3) Composite material blocking and molding Composite materials are a rookie of materials science, but so far, the preparation of composite materials and its large-scale timber is still a problem. The semisolid continuous casting in solve this problem will have a brilliant future, It has been confirmed by numerous test institute. In a word, The semisolid continuous casting technology in high alloy material, difficult deformation, fine crystal homogenizing steel materials and high value-added new materials forming has a unique technical advantages. Basic function: 1,have the input voltage, output current dial indicator, working frequency, working voltage digital indicator. 2,Current and frequency in setting within the scope of work infinitely variable control. 3,System in the mixing state can be changed by adjusting the voltage working current. 4,The system is equipped with continuous and time setting two kinds of working mode, under any mode it have clockwise stirring, anticlockwise stirring and automatic mixing the three kinds of mixing way, any stirring condition the mixing time, stop time, commutation stop time can be within the scope of the parameters set arbitrary. 5,Fault indicator is divided into system outage, mixing stop failure and alarm failure three categories. A, System outage: including the cooling fan failure, the IPM module failure, rectifier fuse failure, main contactor of failure and the control of the power failure, etc. B, mixing stop failures: Including: a serious shortage of water, agitator winding serious overheating, the cooling fan stop. C, Alarm failure: including the shortage of water flow and water pressure, over-current and under-voltage unbalanced three phase current, etc.

Outlook Although the semisolid continuous casting technology haven't reached the level of large-scale industrial application, But in the existing experimental research and small-scale production has shown a strong vitality. Synthesizing the relevant research both at home and abroad is not hard to see, semi-solid casting technology in the following areas has a bright application prospect: (1) High alloy and difficult deformation material forming High alloy materials and difficult deformation material forming has been a difficult problem in the field of material processing. The semisolid continuous casting billet in the semi-solid temperature has the similar advantage of the liquid molding directly, for high alloy material no segregation, no defects casting and difficult deformation material forming smoothly found a feasible technical route. The research team researches show that, usually think not of forging white iron and high manganese steel, After made of semi-solid casting billet, in the semi-solid temperature molding thickness 2 mm, a length of more than 100 mm complex parts. Therefore, the semisolid continuous casting in terms of difficult deformation material molding with billet production will have a brilliant future. (2) The development of a new generation steel and iron material Now all countries in the world in the super steel research, our country also has been started important basic planning project“A new generation of iron and steel materials research”. A new generation of iron and steel material requires high clean, ultrafine, ultra-high strength, at the same time also has the potential of large scale application. In order to achieve this goal, will need to adopt continuous casting technology to made blank, while the existing continuous casting billet are widespread columnar crystal area is big, the macro segregation seriously flawed. The semisolid continuous casting billet tiny grains, less of macrosegregation advantage will no doubt be less for a new generation of iron and steel material blocking a worth exploring the technical route. (3) Composite material blocking and molding Composite materials are a rookie of materials science, but so far, the preparation of composite materials and its large-scale timber is still a problem. The semisolid continuous casting in solve this problem will have a brilliant future, It has been confirmed by numerous test institute. In a word, The semisolid continuous casting technology in high alloy material, difficult deformation, fine crystal homogenizing steel materials and high value-added new materials forming has a unique technical advantages. Basic function: 1,have the input voltage, output current dial indicator, working frequency, working voltage digital indicator. 2,Current and frequency in setting within the scope of work infinitely variable control. 3,System in the mixing state can be changed by adjusting the voltage working current. 4,The system is equipped with continuous and time setting two kinds of working mode, under any mode it have clockwise stirring, anticlockwise stirring and automatic mixing the three kinds of mixing way, any stirring condition the mixing time, stop time, commutation stop time can be within the scope of the parameters set arbitrary. 5,Fault indicator is divided into system outage, mixing stop failure and alarm failure three categories. A, System outage: including the cooling fan failure, the IPM module failure, rectifier fuse failure, main contactor of failure and the control of the power failure, etc. B, mixing stop failures: Including: a serious shortage of water, agitator winding serious overheating, the cooling fan stop. C, Alarm failure: including the shortage of water flow and water pressure, over-current and under-voltage unbalanced three phase current, etc.

Outlook Although the semisolid continuous casting technology haven't reached the level of large-scale industrial application, But in the existing experimental research and small-scale production has shown a strong vitality. Synthesizing the relevant research both at home and abroad is not hard to see, semi-solid casting technology in the following areas has a bright application prospect: (1) High alloy and difficult deformation material forming High alloy materials and difficult deformation material forming has been a difficult problem in the field of material processing. The semisolid continuous casting billet in the semi-solid temperature has the similar advantage of the liquid molding directly, for high alloy material no segregation, no defects casting and difficult deformation material forming smoothly found a feasible technical route. The research team researches show that, usually think not of forging white iron and high manganese steel, After made of semi-solid casting billet, in the semi-solid temperature molding thickness 2 mm, a length of more than 100 mm complex parts. Therefore, the semisolid continuous casting in terms of difficult deformation material molding with billet production will have a brilliant future. (2) The development of a new generation steel and iron material Now all countries in the world in the super steel research, our country also has been started important basic planning project“A new generation of iron and steel materials research”. A new generation of iron and steel material requires high clean, ultrafine, ultra-high strength, at the same time also has the potential of large scale application. In order to achieve this goal, will need to adopt continuous casting technology to made blank, while the existing continuous casting billet are widespread columnar crystal area is big, the macro segregation seriously flawed. The semisolid continuous casting billet tiny grains, less of macrosegregation advantage will no doubt be less for a new generation of iron and steel material blocking a worth exploring the technical route. (3) Composite material blocking and molding Composite materials are a rookie of materials science, but so far, the preparation of composite materials and its large-scale timber is still a problem. The semisolid continuous casting in solve this problem will have a brilliant future, It has been confirmed by numerous test institute. In a word, The semisolid continuous casting technology in high alloy material, difficult deformation, fine crystal homogenizing steel materials and high value-added new materials forming has a unique technical advantages. Basic function: 1,have the input voltage, output current dial indicator, working frequency, working voltage digital indicator. 2,Current and frequency in setting within the scope of work infinitely variable control. 3,System in the mixing state can be changed by adjusting the voltage working current. 4,The system is equipped with continuous and time setting two kinds of working mode, under any mode it have clockwise stirring, anticlockwise stirring and automatic mixing the three kinds of mixing way, any stirring condition the mixing time, stop time, commutation stop time can be within the scope of the parameters set arbitrary. 5,Fault indicator is divided into system outage, mixing stop failure and alarm failure three categories. A, System outage: including the cooling fan failure, the IPM module failure, rectifier fuse failure, main contactor of failure and the control of the power failure, etc. B, mixing stop failures: Including: a serious shortage of water, agitator winding serious overheating, the cooling fan stop. C, Alarm failure: including the shortage of water flow and water pressure, over-current and under-voltage unbalanced three phase current, etc.

Outlook Although the semisolid continuous casting technology haven't reached the level of large-scale industrial application, But in the existing experimental research and small-scale production has shown a strong vitality. Synthesizing the relevant research both at home and abroad is not hard to see, semi-solid casting technology in the following areas has a bright application prospect: (1) High alloy and difficult deformation material forming High alloy materials and difficult deformation material forming has been a difficult problem in the field of material processing. The semisolid continuous casting billet in the semi-solid temperature has the similar advantage of the liquid molding directly, for high alloy material no segregation, no defects casting and difficult deformation material forming smoothly found a feasible technical route. The research team researches show that, usually think not of forging white iron and high manganese steel, After made of semi-solid casting billet, in the semi-solid temperature molding thickness 2 mm, a length of more than 100 mm complex parts. Therefore, the semisolid continuous casting in terms of difficult deformation material molding with billet production will have a brilliant future. (2) The development of a new generation steel and iron material Now all countries in the world in the super steel research, our country also has been started important basic planning project“A new generation of iron and steel materials research”. A new generation of iron and steel material requires high clean, ultrafine, ultra-high strength, at the same time also has the potential of large scale application. In order to achieve this goal, will need to adopt continuous casting technology to made blank, while the existing continuous casting billet are widespread columnar crystal area is big, the macro segregation seriously flawed. The semisolid continuous casting billet tiny grains, less of macrosegregation advantage will no doubt be less for a new generation of iron and steel material blocking a worth exploring the technical route. (3) Composite material blocking and molding Composite materials are a rookie of materials science, but so far, the preparation of composite materials and its large-scale timber is still a problem. The semisolid continuous casting in solve this problem will have a brilliant future, It has been confirmed by numerous test institute. In a word, The semisolid continuous casting technology in high alloy material, difficult deformation, fine crystal homogenizing steel materials and high value-added new materials forming has a unique technical advantages. Basic function: 1,have the input voltage, output current dial indicator, working frequency, working voltage digital indicator. 2,Current and frequency in setting within the scope of work infinitely variable control. 3,System in the mixing state can be changed by adjusting the voltage working current. 4,The system is equipped with continuous and time setting two kinds of working mode, under any mode it have clockwise stirring, anticlockwise stirring and automatic mixing the three kinds of mixing way, any stirring condition the mixing time, stop time, commutation stop time can be within the scope of the parameters set arbitrary. 5,Fault indicator is divided into system outage, mixing stop failure and alarm failure three categories. A, System outage: including the cooling fan failure, the IPM module failure, rectifier fuse failure, main contactor of failure and the control of the power failure, etc. B, mixing stop failures: Including: a serious shortage of water, agitator winding serious overheating, the cooling fan stop. C, Alarm failure: including the shortage of water flow and water pressure, over-current and under-voltage unbalanced three phase current, etc. Related Keywords

Related Keywords

You May Also Like

You May Also Like