API 610 Standard waste oil pump

- Delivery Time:

- 7 Days

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description Specification:

Product Description Specification: Size (discharge): 25mm to 450mm

Capacity: 3.4~ 1200 m3/hr

Head: 6m ~ 135 m

Efficiency:Up to 92%

Materials:Cast iron,SS 304,SS 316,Bronze etc

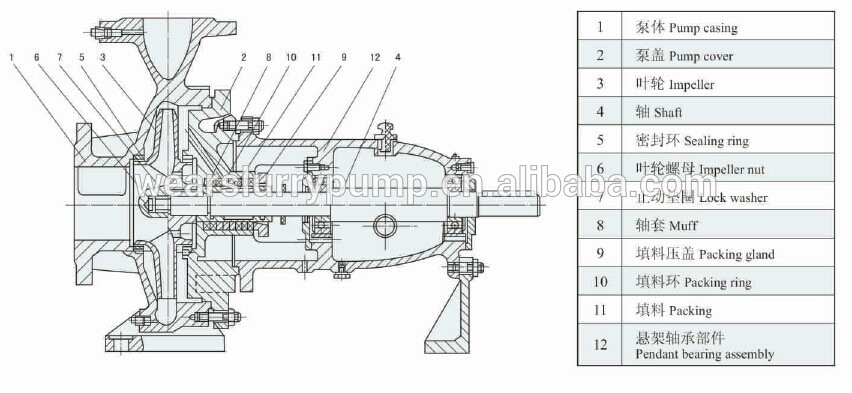

API 610 Standard MZ Centrifugal Oil Pump is a horizontal, single-stage, single-suction and cantilever centrifugal pump, its size and property conform to the API 610 standard. It's applicable for transporting medium being low-temperature or high-temperature, neutral or corrosive, being clean or containing solid grains, or being poisonous, inflammable or explosive. It's mainly applied in such industries as chemical, chemical fertilizer, petroleum, metallurgy, electricity, papermaking, pharmacy, foodstuff and fibre etc.. Detailed specification:

Item | API 610 Centrifugal Oil Pump |

Pump type | End Suction Oil Pump |

Model | MS |

Materials | Cast iron,SS 304,SS316L,Bronze etc |

Driven Type | Electric motor or Diesel engine |

Structure | Horizontal end suction oil pump |

Seal | Packing seal or Mechanical seal |

Drive | Coupling |

Rotate | Clockwise |

Theory | Centrifugal Oil Pump |

Structure | Single-stage Oil Pump |

Usage | chemical engineering, petrochemicals, steel works, power plants, papermaking, pulp, medicine, food and sugar refining |

Standard or Nonstandard | API 610 Standard |

Application | neutral or corrosive, being clean or containing solid grains |

Outlet Diameter | 25-450mm |

Capacity | 3.4-1200 m3/h |

Head | 3.7-135m |

Rotation Speed | 980-2950r/min |

Power | 7.5-185kW |

Certificate | ISO9001 |

Feature | High efficiency,Easy maintenance |

Pump Type | Capacity (m3/h) | Head (m) | Power (KW) |

MZ50 | 3.4-15 | 3.7-68.8 | 0.55-11 |

MZ65 | 6.8-30 | 3.7-126.8 | 0.55-30 |

MZ80 | 13.6-60 | 3.6-128 | 0.55-45 |

MZ100 | 27.3-120 | 3.4-115.5 | 1.5-75 |

MZ125 | 56-240 | 8.5-132.5 | 2.2-110 |

MZ150 | 99-240 | 12.4-57.5 | 15-55 |

MZ200 | 197.7-460 | 14.8-55.8 | 30-90 |

API 610 Standard MZ Centrifugal Oil Pump Display:

API 610 Standard MZ Centrifugal Oil Pump Display:

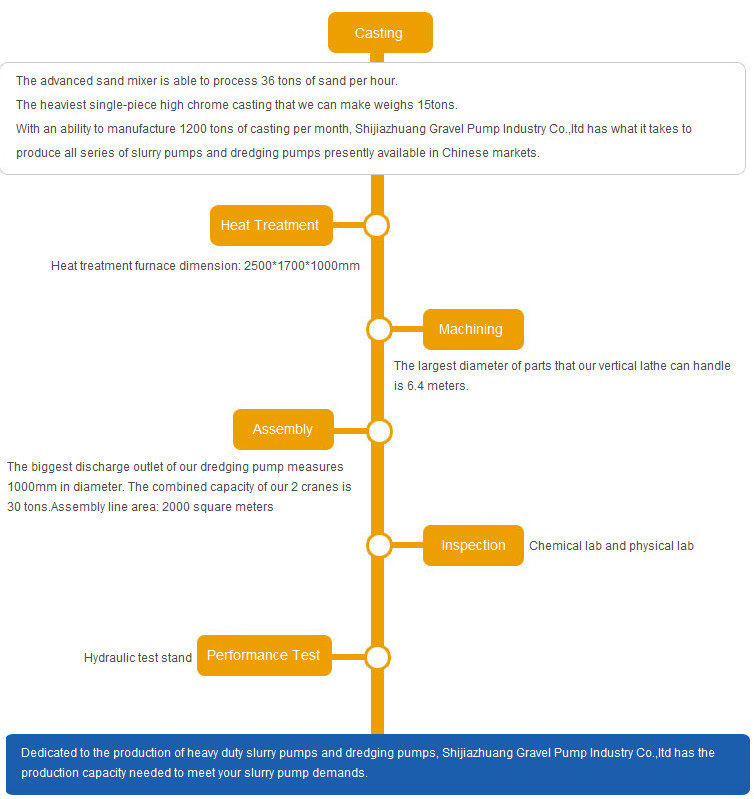

API 610 Standard MZ Centrifugal Oil Pump Production Process:

API 610 Standard MZ Centrifugal Oil Pump Production Process:  Packing & Shipping Testing

Packing & Shipping Testing  Quality control:

Quality control: Stages of manufacture | Quality cotrol activities |

| Raw material arrival | Sampling, material chemical analysis |

| Casting and composition | Material material chemical analysis of pump parts |

| Casting quality inspection | |

| Key component machining | Dimension precision inspection |

| Impeller balancing | |

| General assembly | Procedure operaion |

| Hydraulic static test | |

Performance test of pump unit | Capacity and head |

| Vibration and noise | |

| Bearing temperature | |

| Final inspection | Packaging of pump unit |

| Documents | |

| Spare parts and accessories |

Our Own Factory

Our Own Factory

FAQ FAQ: 1.Q:Are you a factory or trading company?

FAQ FAQ: 1.Q:Are you a factory or trading company? A:We are a factory.

2.Q:Where is your factory located? How can I visit there?

A:Our factory is located in Shijiazhuang City, Hebei Province, China.You can fly to Shijiazhuang airport directly.All our clients, from home or abroad, are warmly welcome to visit us! 3.Q:What is The material of your products? A: The material is High chrome alloy or Rubber. We can also choose material as customers’ requirement.

4.Q:How can I get some samples?

A: We are honored to offer you samples.

5.Q:How does your factory do regarding quality control?

A:"Quality is priority. we always attach great importance to quality controlling from the very beginning to the very end. Our factory has 15~20QC. Contact Person

Related Keywords