Cutter Dredging Pump Casing Body Slurry Pump Spare Parts

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

Company Information Shijiazhuang Gravel Slurry Pump Industry Co.,ltd locates in Shijiazhuang, Hebei Province, China, it is an integrative production, research, design and sales company, specialized in manufacturing slurry pump products. The company acting as one of the national heavy machinery industry unit, now has been developed into a professional manufacturer of slurry pump, mud pump, slush pump, foam pump, sand-slurry pump. Cutter Dredging Pump Casing Body Slurry Pump Spare Parts

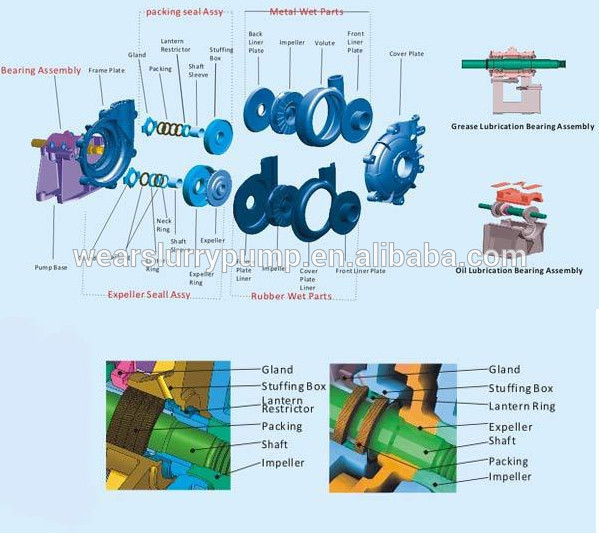

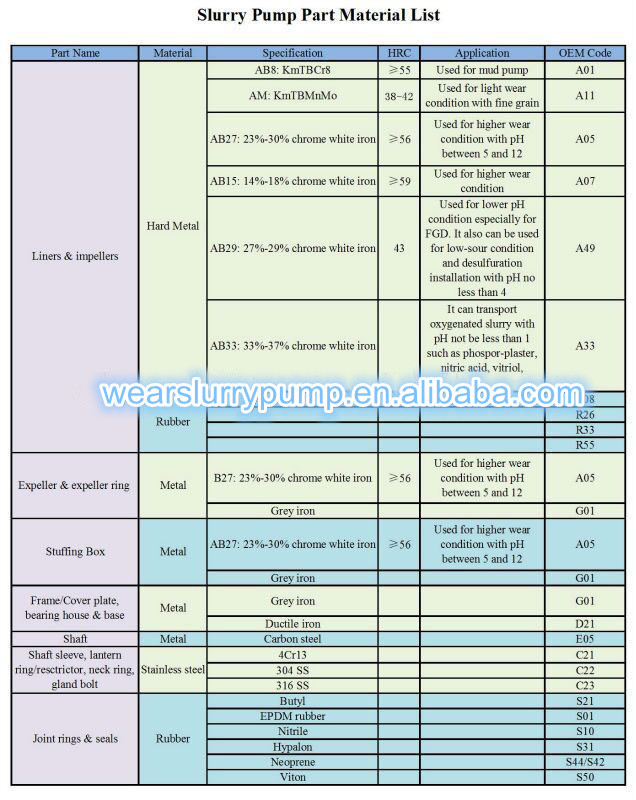

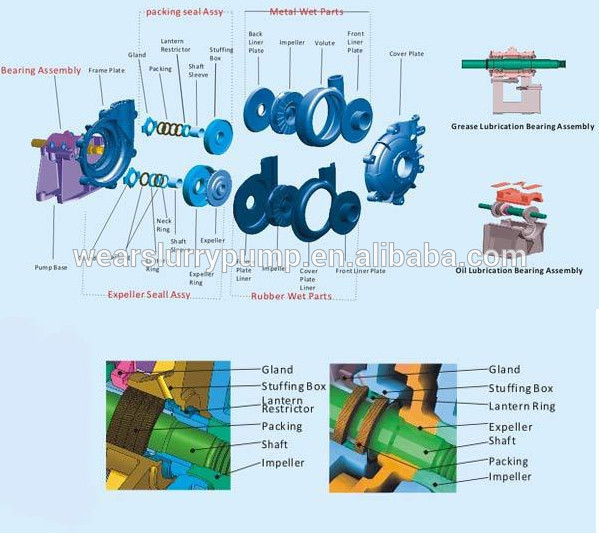

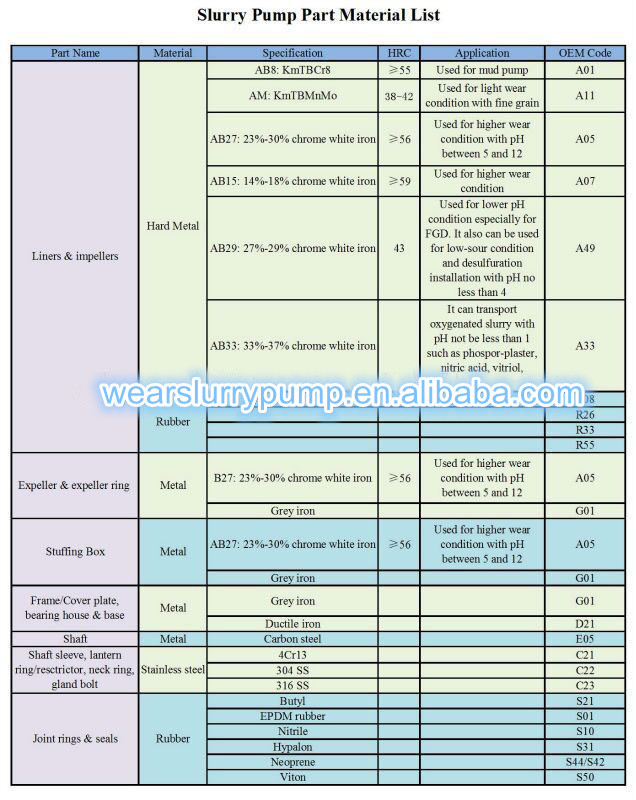

Advantage of our slurry pump: Competitive price; short lead time; powerful technical support for pump selection and problem solving 1. What is a slurry pump cover plate? Most slurry pump casings are "slower" than their water pump cousins, primarily to reduce wear though lower internal velcocities. The casing shape is generally of a semi-volute or annual geometry, with large clearance at the cutwater. Efficiencies of the more open casings are less than that of the volute type, however, they appear to offer the best copromise in terms of wear life. 2. Mainly slurry pump spare parts Naipu Slurry pump and standard spare parts with high anti-abrosive can be supply with huge amount within a short period. Impeller, Casing, shaft, throat bush, wear plate, case, cover, stuffing box, lantern restrictor, cover plate bolt, volute, throat bush, shaft sleeve, cover plate liner, frame plate liner... 3. What material does the spares including? Slurry pump cover plate part code: B1013, B15013, C2013, D3013, E4013, F6013, G8013, G10013, G12013, H14013 ... 1) Material: D21, G01, A05... 2) Shaft material: 45#, 40Cr, SS304, SS315... 3) Shaft sleeve material: 3Cr13, 4Cr13, SS304, SS316... 4) Lantern ring material: 304, 316, PTFE, Cu... 5) Bearing housing/ bearing end cover material: G01, D21... 6) Wet end part material: A05, A07, A49, A51, A33, A61, R08, R26, R33, R38, R55, S01, S12, S21, S42, S50, U01, EPDM, PU, CR... Single Stage Slurry Pump Rubber Lined Wet End Parts detail application: Competitive price; short lead time; powerful technical support for pump selection and problem solving The Impeller is one of the most important parts of slurry pump. Centrifugal pumps need impeller to produce the centrifugal force which transfer the slurries. The centrifugal force is produced by the impeller which rotates to a certain speed. our pump offers two solutions for the problem of long service life. We choose the white iron, high chrome (27%) for the strong abrasive slurries with sharp particles. For the corrosive slurries with blunt particles, we recommend the natural rubber. Single Stage Slurry Pump Rubber Lined Wet End Parts feature: Design: Scientific design based on hydraulic theories

Advantage of our slurry pump: Competitive price; short lead time; powerful technical support for pump selection and problem solving 1. What is a slurry pump cover plate? Most slurry pump casings are "slower" than their water pump cousins, primarily to reduce wear though lower internal velcocities. The casing shape is generally of a semi-volute or annual geometry, with large clearance at the cutwater. Efficiencies of the more open casings are less than that of the volute type, however, they appear to offer the best copromise in terms of wear life. 2. Mainly slurry pump spare parts Naipu Slurry pump and standard spare parts with high anti-abrosive can be supply with huge amount within a short period. Impeller, Casing, shaft, throat bush, wear plate, case, cover, stuffing box, lantern restrictor, cover plate bolt, volute, throat bush, shaft sleeve, cover plate liner, frame plate liner... 3. What material does the spares including? Slurry pump cover plate part code: B1013, B15013, C2013, D3013, E4013, F6013, G8013, G10013, G12013, H14013 ... 1) Material: D21, G01, A05... 2) Shaft material: 45#, 40Cr, SS304, SS315... 3) Shaft sleeve material: 3Cr13, 4Cr13, SS304, SS316... 4) Lantern ring material: 304, 316, PTFE, Cu... 5) Bearing housing/ bearing end cover material: G01, D21... 6) Wet end part material: A05, A07, A49, A51, A33, A61, R08, R26, R33, R38, R55, S01, S12, S21, S42, S50, U01, EPDM, PU, CR... Single Stage Slurry Pump Rubber Lined Wet End Parts detail application: Competitive price; short lead time; powerful technical support for pump selection and problem solving The Impeller is one of the most important parts of slurry pump. Centrifugal pumps need impeller to produce the centrifugal force which transfer the slurries. The centrifugal force is produced by the impeller which rotates to a certain speed. our pump offers two solutions for the problem of long service life. We choose the white iron, high chrome (27%) for the strong abrasive slurries with sharp particles. For the corrosive slurries with blunt particles, we recommend the natural rubber. Single Stage Slurry Pump Rubber Lined Wet End Parts feature: Design: Scientific design based on hydraulic theories

Production: Strict manufacture procedures and specialized QC personnel

Material: Various materials for different applications

Life: Long service life Single Stage Slurry Pump Rubber Lined Wet End Parts material of slurry pump: Single Stage Slurry Pump Rubber Lined Wet End Parts Component Diagram:

Single Stage Slurry Pump Rubber Lined Wet End Parts Component Diagram:

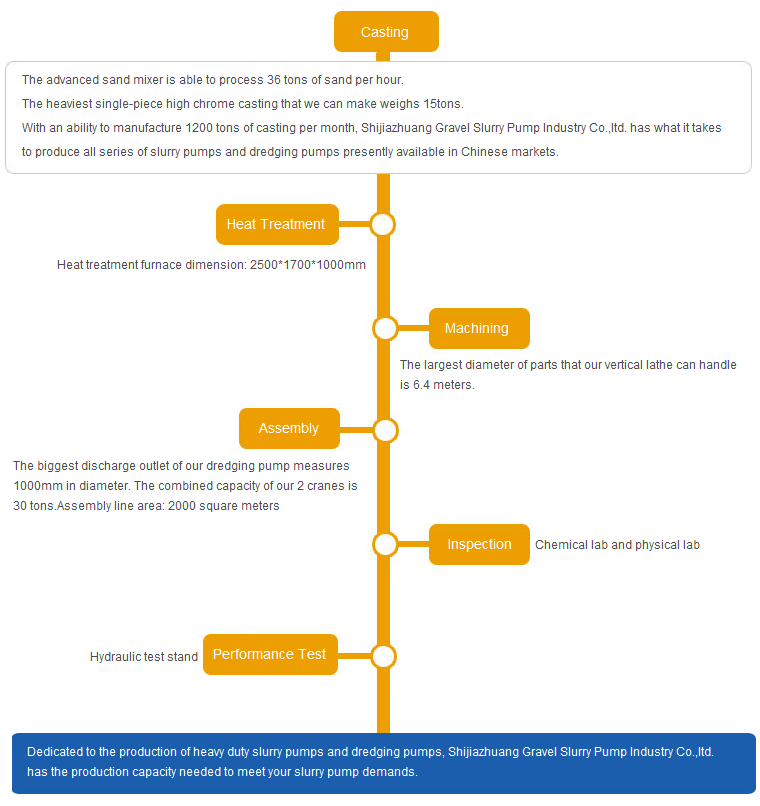

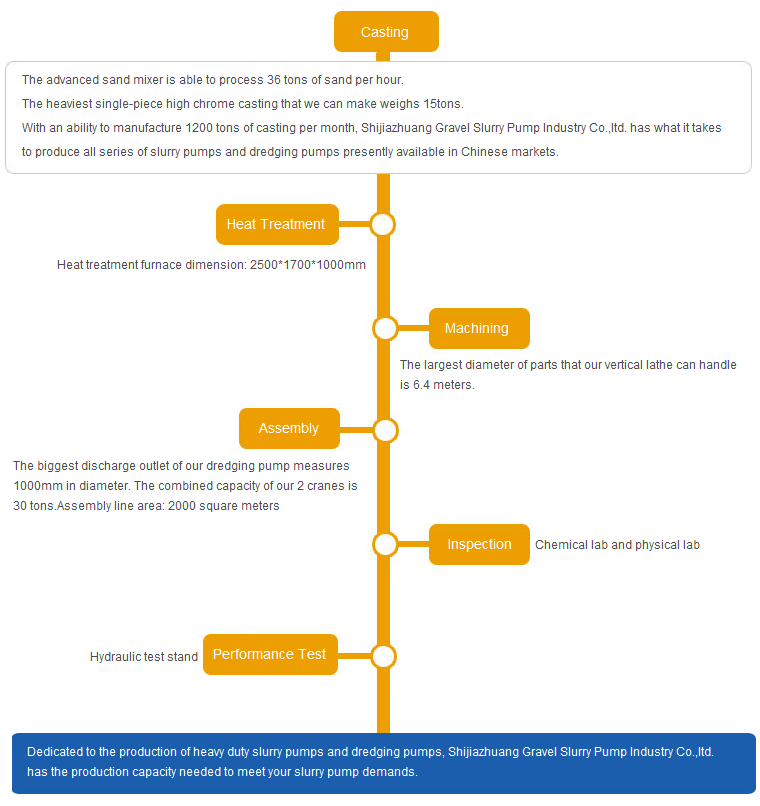

production process

production process

Working alive station: Shijiazhuang Gravel Slurry Pump Industry Co.,ltdhave firstclass production equipment.There are more than 100 sets of equipments,such as lost foam casting production line,shot last machine,heat treatment furnace,CNC lather,digital display large vertical lather,digital display horizontal milling machine,etc.

quality control

quality control

Packing &Shipping:

Packing &Shipping:

Our Services OEM service: Produce the pump and spare parts according to client's drawing or sample. Pump slection: Help customers select the type, size and operating speed of pumps that will perform at the lowest cost. Using service :Offer Design, Installation, Repair and Maintenance solutions and Mine measuring up service. Quality control :Pay more attention to the quality in every process with different instruments. Material service :Interchangeable metal design allow best material choice for any application. After-sales service: Provide lifetime after sale service to solve any question during uses and large stock for standard spare parts. Guarantee :One year guarantee for whole machine except of the wet end parts. FAQ 1.Are you a manufacturer? Yes, we have been in manufacturing and marketing industry centrifugal pump over 10 years. 2.What information should I let you know if I want to get a quotation? Pump capacity, pump head, medium, medium temperature, pump material, quantity, if possible, please alsoprovide the pump model you are using now, price will be calculated as per the pump model, if not, we will recommend relevant product for reference. 3.Q:Where is your factory located? How can I visit there? A:Our factory is located in Shijiazhuang City, Hebei Province, China.You can fly to Shijiazhuang airport directly.All our clients, from home or abroad, are warmly welcome to visit us! 4.Do you impact the finished product? Yes, each batch of production and finished product will be quality checked strictly before delivering. Contact us

Our Services OEM service: Produce the pump and spare parts according to client's drawing or sample. Pump slection: Help customers select the type, size and operating speed of pumps that will perform at the lowest cost. Using service :Offer Design, Installation, Repair and Maintenance solutions and Mine measuring up service. Quality control :Pay more attention to the quality in every process with different instruments. Material service :Interchangeable metal design allow best material choice for any application. After-sales service: Provide lifetime after sale service to solve any question during uses and large stock for standard spare parts. Guarantee :One year guarantee for whole machine except of the wet end parts. FAQ 1.Are you a manufacturer? Yes, we have been in manufacturing and marketing industry centrifugal pump over 10 years. 2.What information should I let you know if I want to get a quotation? Pump capacity, pump head, medium, medium temperature, pump material, quantity, if possible, please alsoprovide the pump model you are using now, price will be calculated as per the pump model, if not, we will recommend relevant product for reference. 3.Q:Where is your factory located? How can I visit there? A:Our factory is located in Shijiazhuang City, Hebei Province, China.You can fly to Shijiazhuang airport directly.All our clients, from home or abroad, are warmly welcome to visit us! 4.Do you impact the finished product? Yes, each batch of production and finished product will be quality checked strictly before delivering. Contact us

Advantage of our slurry pump: Competitive price; short lead time; powerful technical support for pump selection and problem solving 1. What is a slurry pump cover plate? Most slurry pump casings are "slower" than their water pump cousins, primarily to reduce wear though lower internal velcocities. The casing shape is generally of a semi-volute or annual geometry, with large clearance at the cutwater. Efficiencies of the more open casings are less than that of the volute type, however, they appear to offer the best copromise in terms of wear life. 2. Mainly slurry pump spare parts Naipu Slurry pump and standard spare parts with high anti-abrosive can be supply with huge amount within a short period. Impeller, Casing, shaft, throat bush, wear plate, case, cover, stuffing box, lantern restrictor, cover plate bolt, volute, throat bush, shaft sleeve, cover plate liner, frame plate liner... 3. What material does the spares including? Slurry pump cover plate part code: B1013, B15013, C2013, D3013, E4013, F6013, G8013, G10013, G12013, H14013 ... 1) Material: D21, G01, A05... 2) Shaft material: 45#, 40Cr, SS304, SS315... 3) Shaft sleeve material: 3Cr13, 4Cr13, SS304, SS316... 4) Lantern ring material: 304, 316, PTFE, Cu... 5) Bearing housing/ bearing end cover material: G01, D21... 6) Wet end part material: A05, A07, A49, A51, A33, A61, R08, R26, R33, R38, R55, S01, S12, S21, S42, S50, U01, EPDM, PU, CR... Single Stage Slurry Pump Rubber Lined Wet End Parts detail application: Competitive price; short lead time; powerful technical support for pump selection and problem solving The Impeller is one of the most important parts of slurry pump. Centrifugal pumps need impeller to produce the centrifugal force which transfer the slurries. The centrifugal force is produced by the impeller which rotates to a certain speed. our pump offers two solutions for the problem of long service life. We choose the white iron, high chrome (27%) for the strong abrasive slurries with sharp particles. For the corrosive slurries with blunt particles, we recommend the natural rubber. Single Stage Slurry Pump Rubber Lined Wet End Parts feature: Design: Scientific design based on hydraulic theories

Advantage of our slurry pump: Competitive price; short lead time; powerful technical support for pump selection and problem solving 1. What is a slurry pump cover plate? Most slurry pump casings are "slower" than their water pump cousins, primarily to reduce wear though lower internal velcocities. The casing shape is generally of a semi-volute or annual geometry, with large clearance at the cutwater. Efficiencies of the more open casings are less than that of the volute type, however, they appear to offer the best copromise in terms of wear life. 2. Mainly slurry pump spare parts Naipu Slurry pump and standard spare parts with high anti-abrosive can be supply with huge amount within a short period. Impeller, Casing, shaft, throat bush, wear plate, case, cover, stuffing box, lantern restrictor, cover plate bolt, volute, throat bush, shaft sleeve, cover plate liner, frame plate liner... 3. What material does the spares including? Slurry pump cover plate part code: B1013, B15013, C2013, D3013, E4013, F6013, G8013, G10013, G12013, H14013 ... 1) Material: D21, G01, A05... 2) Shaft material: 45#, 40Cr, SS304, SS315... 3) Shaft sleeve material: 3Cr13, 4Cr13, SS304, SS316... 4) Lantern ring material: 304, 316, PTFE, Cu... 5) Bearing housing/ bearing end cover material: G01, D21... 6) Wet end part material: A05, A07, A49, A51, A33, A61, R08, R26, R33, R38, R55, S01, S12, S21, S42, S50, U01, EPDM, PU, CR... Single Stage Slurry Pump Rubber Lined Wet End Parts detail application: Competitive price; short lead time; powerful technical support for pump selection and problem solving The Impeller is one of the most important parts of slurry pump. Centrifugal pumps need impeller to produce the centrifugal force which transfer the slurries. The centrifugal force is produced by the impeller which rotates to a certain speed. our pump offers two solutions for the problem of long service life. We choose the white iron, high chrome (27%) for the strong abrasive slurries with sharp particles. For the corrosive slurries with blunt particles, we recommend the natural rubber. Single Stage Slurry Pump Rubber Lined Wet End Parts feature: Design: Scientific design based on hydraulic theories Production: Strict manufacture procedures and specialized QC personnel

Material: Various materials for different applications

Life: Long service life Single Stage Slurry Pump Rubber Lined Wet End Parts material of slurry pump:

Single Stage Slurry Pump Rubber Lined Wet End Parts Component Diagram:

Single Stage Slurry Pump Rubber Lined Wet End Parts Component Diagram:

production process

production process

Working alive station: Shijiazhuang Gravel Slurry Pump Industry Co.,ltdhave firstclass production equipment.There are more than 100 sets of equipments,such as lost foam casting production line,shot last machine,heat treatment furnace,CNC lather,digital display large vertical lather,digital display horizontal milling machine,etc.

quality control

quality control Stages of manufacture | Quality cotrol activities |

| Raw material arrival | Sampling, material chemical analysis |

| Casting and composition | Material material chemical analysis of pump parts |

| Casting quality inspection | |

| Key component machining | Dimension precision inspection |

| Impeller balancing | |

| General assembly | Procedure operaion |

| Hydraulic static test | |

Performance test of pump unit | Capacity and head |

| Vibration and noise | |

| Bearing temperature | |

| Final inspection | Packaging of pump unit |

| Documents | |

| Spare parts and accessories |

Packing &Shipping:

Packing &Shipping:

Our Services OEM service: Produce the pump and spare parts according to client's drawing or sample. Pump slection: Help customers select the type, size and operating speed of pumps that will perform at the lowest cost. Using service :Offer Design, Installation, Repair and Maintenance solutions and Mine measuring up service. Quality control :Pay more attention to the quality in every process with different instruments. Material service :Interchangeable metal design allow best material choice for any application. After-sales service: Provide lifetime after sale service to solve any question during uses and large stock for standard spare parts. Guarantee :One year guarantee for whole machine except of the wet end parts. FAQ 1.Are you a manufacturer? Yes, we have been in manufacturing and marketing industry centrifugal pump over 10 years. 2.What information should I let you know if I want to get a quotation? Pump capacity, pump head, medium, medium temperature, pump material, quantity, if possible, please alsoprovide the pump model you are using now, price will be calculated as per the pump model, if not, we will recommend relevant product for reference. 3.Q:Where is your factory located? How can I visit there? A:Our factory is located in Shijiazhuang City, Hebei Province, China.You can fly to Shijiazhuang airport directly.All our clients, from home or abroad, are warmly welcome to visit us! 4.Do you impact the finished product? Yes, each batch of production and finished product will be quality checked strictly before delivering. Contact us

Our Services OEM service: Produce the pump and spare parts according to client's drawing or sample. Pump slection: Help customers select the type, size and operating speed of pumps that will perform at the lowest cost. Using service :Offer Design, Installation, Repair and Maintenance solutions and Mine measuring up service. Quality control :Pay more attention to the quality in every process with different instruments. Material service :Interchangeable metal design allow best material choice for any application. After-sales service: Provide lifetime after sale service to solve any question during uses and large stock for standard spare parts. Guarantee :One year guarantee for whole machine except of the wet end parts. FAQ 1.Are you a manufacturer? Yes, we have been in manufacturing and marketing industry centrifugal pump over 10 years. 2.What information should I let you know if I want to get a quotation? Pump capacity, pump head, medium, medium temperature, pump material, quantity, if possible, please alsoprovide the pump model you are using now, price will be calculated as per the pump model, if not, we will recommend relevant product for reference. 3.Q:Where is your factory located? How can I visit there? A:Our factory is located in Shijiazhuang City, Hebei Province, China.You can fly to Shijiazhuang airport directly.All our clients, from home or abroad, are warmly welcome to visit us! 4.Do you impact the finished product? Yes, each batch of production and finished product will be quality checked strictly before delivering. Contact us

Related Keywords

Related Keywords

You May Also Like

You May Also Like