Centrifugal motar pump

- Delivery Time:

- 3 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

Specifications Centrifugal motar pump

Thick liner & impeller

A05 high chrome alloy

Heavy duty frame & bearing

High efficiency

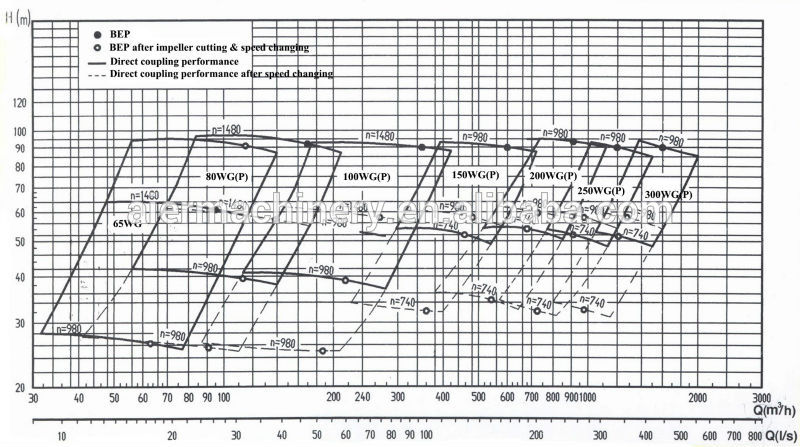

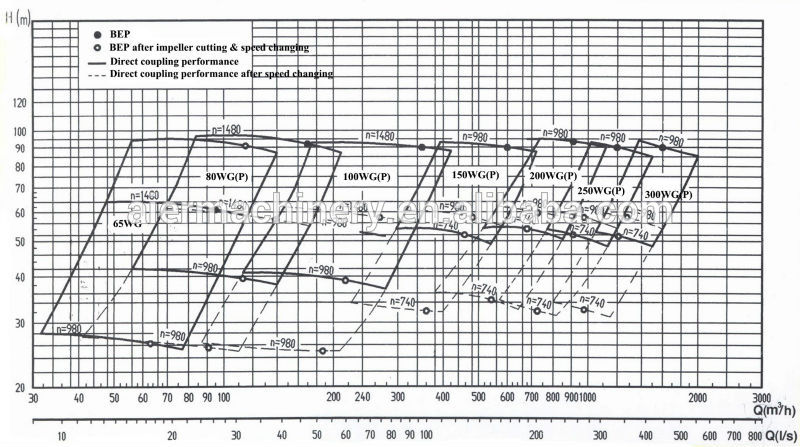

WG centrifugal motar pump WG centrifugal motar pump is horizontal, single-stage, single-suction, cantilever, double-casing, centrifugal slurry pump. Features: CAD modern design, super hydraulic performance, and lower abrasion rate; High efficiency: up to 81% High head: up to 100 m Wide passage, non-clogging and good performance of NPSH; Expeller seal combined with packing seal and mechanical seal have been adopted to guarantee the slurry from leakage; Reliability design ensures long MTBF (mean time between events); Adopting metric bearing with oil lubrication, reasonable lubrication and cooling systems to ensure the bearing to run on the status of low temperature; The wet parts are made of special material which has good performance of abrasion-resistant and corrosive resistant; The pumps can be used for seawater ash-removing to prevent it from the corrosion of seawater, salt and mist, and electrochemical corrsion; The pumps can be installed in series with multi-stage within allowable pressure. Compared with AH slurry pump: 1. Thicker liners and impeller for a better wear life; 2. High capacity frame and bearing to reduce potential running problems; 3. Higher efficiency and higher discharge head for advanced impeller design; 4. Direct coupled, not V belt. Flow rates and discharge heads changes with different impeller diameter; 5. WG high chrome slurry pumps can replace AHP slurry pumps for series pumping. Applications: WG high chrome slurry pumps are widely used for handling the mixture of abrasive and corrosive solids in the field of metallurgy industry, mining industry, and chemical industry, special for handling ash and sludge of electric power station. Wet parts: Material: the same wear resistant high chrome alloy with AH slurry pumps. The wet parts of WG and WG(P) high chrome slurry pump at the same outlet diameter can be interchangeable. Their outline installation dimensions are one and the same. Frame: For the drive part of the WG(P) high chrome slurry pumps, the horizontal split frame with oil lubrication and two sets of cooling systems inside and outside has been adopt. If necessary, cooling water can be supplied. Seal: Two kinds of shaft seal--expeller seal combined with packing seal and mechanical seal. The mechanical seal supplied with high pressure sealing water is recommended when the slurry pump is operated in series (two stages and above two stages), and the expeller seal combined with packing seal is used in single-stage. Slurry Pump Part Material

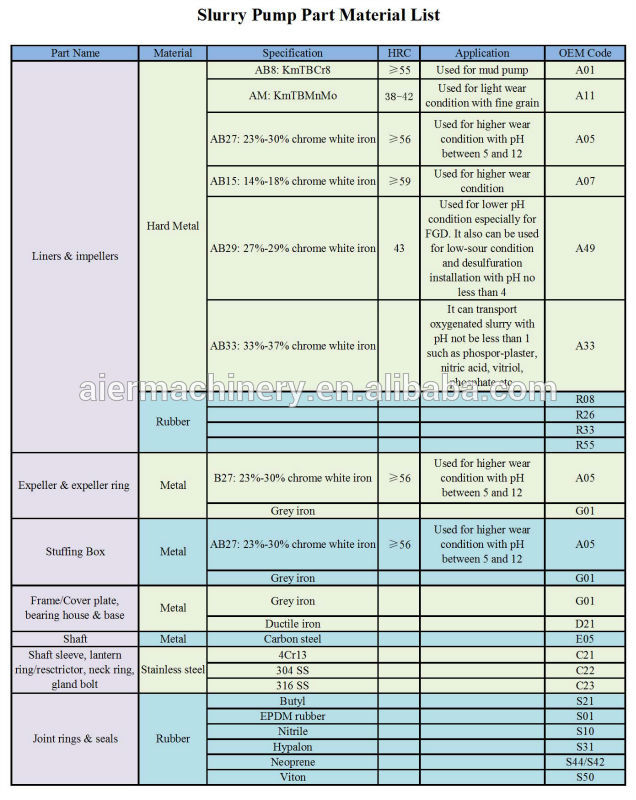

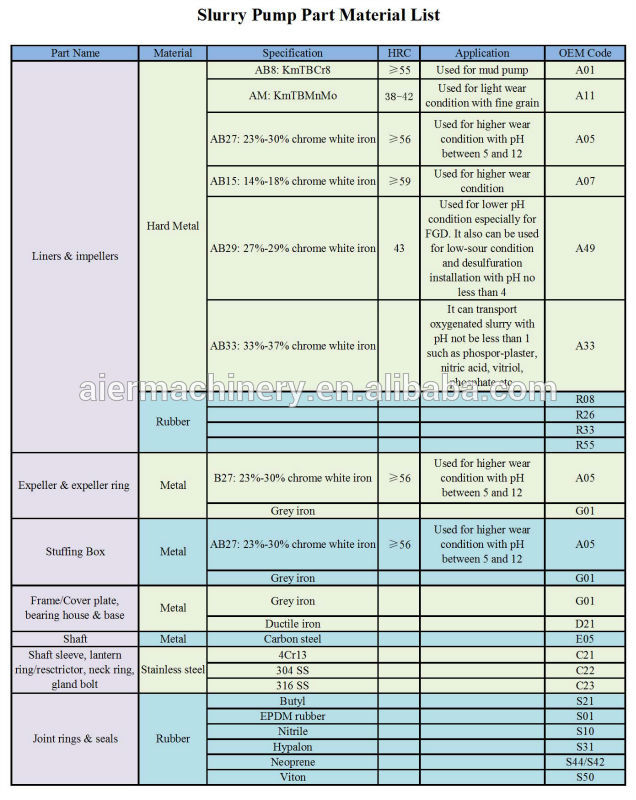

Wet parts: Material: the same wear resistant high chrome alloy with AH slurry pumps. The wet parts of WG and WG(P) high chrome slurry pump at the same outlet diameter can be interchangeable. Their outline installation dimensions are one and the same. Frame: For the drive part of the WG(P) high chrome slurry pumps, the horizontal split frame with oil lubrication and two sets of cooling systems inside and outside has been adopt. If necessary, cooling water can be supplied. Seal: Two kinds of shaft seal--expeller seal combined with packing seal and mechanical seal. The mechanical seal supplied with high pressure sealing water is recommended when the slurry pump is operated in series (two stages and above two stages), and the expeller seal combined with packing seal is used in single-stage. Slurry Pump Part Material

Note: For WG slurry pumps, only high chrome lined pumps available.

Thick liner & impeller

A05 high chrome alloy

Heavy duty frame & bearing

High efficiency

WG centrifugal motar pump WG centrifugal motar pump is horizontal, single-stage, single-suction, cantilever, double-casing, centrifugal slurry pump. Features: CAD modern design, super hydraulic performance, and lower abrasion rate; High efficiency: up to 81% High head: up to 100 m Wide passage, non-clogging and good performance of NPSH; Expeller seal combined with packing seal and mechanical seal have been adopted to guarantee the slurry from leakage; Reliability design ensures long MTBF (mean time between events); Adopting metric bearing with oil lubrication, reasonable lubrication and cooling systems to ensure the bearing to run on the status of low temperature; The wet parts are made of special material which has good performance of abrasion-resistant and corrosive resistant; The pumps can be used for seawater ash-removing to prevent it from the corrosion of seawater, salt and mist, and electrochemical corrsion; The pumps can be installed in series with multi-stage within allowable pressure. Compared with AH slurry pump: 1. Thicker liners and impeller for a better wear life; 2. High capacity frame and bearing to reduce potential running problems; 3. Higher efficiency and higher discharge head for advanced impeller design; 4. Direct coupled, not V belt. Flow rates and discharge heads changes with different impeller diameter; 5. WG high chrome slurry pumps can replace AHP slurry pumps for series pumping. Applications: WG high chrome slurry pumps are widely used for handling the mixture of abrasive and corrosive solids in the field of metallurgy industry, mining industry, and chemical industry, special for handling ash and sludge of electric power station.

Wet parts: Material: the same wear resistant high chrome alloy with AH slurry pumps. The wet parts of WG and WG(P) high chrome slurry pump at the same outlet diameter can be interchangeable. Their outline installation dimensions are one and the same. Frame: For the drive part of the WG(P) high chrome slurry pumps, the horizontal split frame with oil lubrication and two sets of cooling systems inside and outside has been adopt. If necessary, cooling water can be supplied. Seal: Two kinds of shaft seal--expeller seal combined with packing seal and mechanical seal. The mechanical seal supplied with high pressure sealing water is recommended when the slurry pump is operated in series (two stages and above two stages), and the expeller seal combined with packing seal is used in single-stage. Slurry Pump Part Material

Wet parts: Material: the same wear resistant high chrome alloy with AH slurry pumps. The wet parts of WG and WG(P) high chrome slurry pump at the same outlet diameter can be interchangeable. Their outline installation dimensions are one and the same. Frame: For the drive part of the WG(P) high chrome slurry pumps, the horizontal split frame with oil lubrication and two sets of cooling systems inside and outside has been adopt. If necessary, cooling water can be supplied. Seal: Two kinds of shaft seal--expeller seal combined with packing seal and mechanical seal. The mechanical seal supplied with high pressure sealing water is recommended when the slurry pump is operated in series (two stages and above two stages), and the expeller seal combined with packing seal is used in single-stage. Slurry Pump Part Material

Note: For WG slurry pumps, only high chrome lined pumps available.

Related Keywords

Related Keywords