HF press machine for plywood chair making

- Delivery Time:

- 45 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

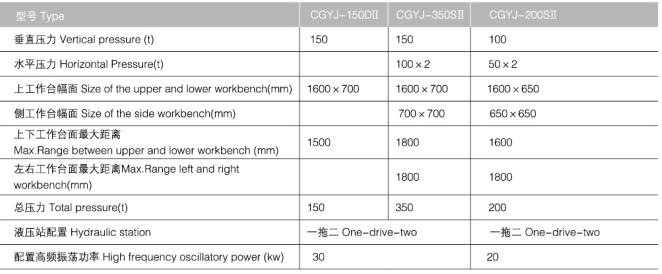

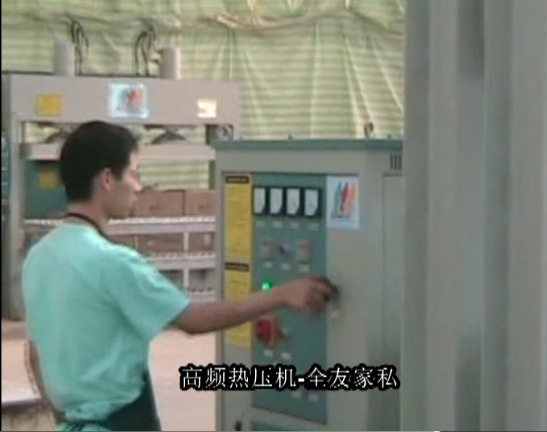

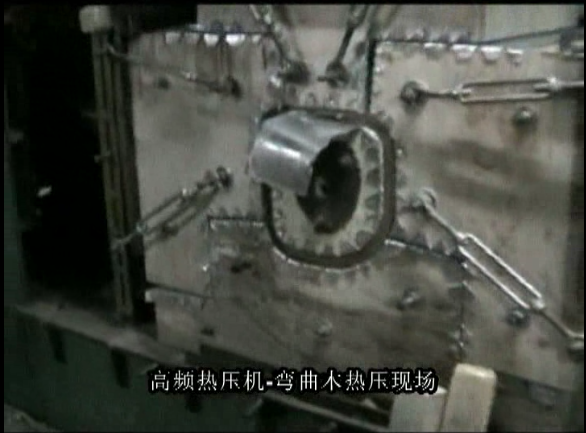

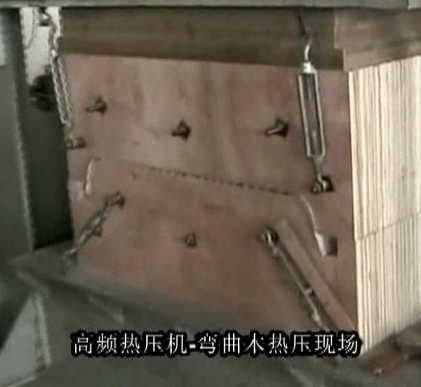

The high frequency hot press machine series make use of the wooden mould forming, which come true gluing of the curved laminated heterotypic products by pressing forming and high frequency heating, widely applied for furniture, musical instrument, shoes industry, decoration, forestry industry and so on. Except of the following products, our company can produce varieties of the non-standard equipment for you, according to your demands. Principal features of HF hot press machine Simple operation, uniform heating, and prompt forming; Wooden mould adopted, low cost, simple replacement process to satisfy different requirements; Single HF can drive multiple presses; Small working area and low labor intensity; Environmental protective, no boiler, ash free and smog free. Applications Gule forming of the bentwood armrest, bentwood shelf, bed strips, unconventional teapoy, bamboo tread; glue forming of stereotypic seat-board, panel furniture headboard, box spring, surface of drawer, arc door; glue forming of chair-board & headboard for the children furniture; glue forming of various bentwood artware. Specifications:

The high frequency hot press machine series make use of the wooden mould forming, which come true gluing of the curved laminated heterotypic products by pressing forming and high frequency heating, widely applied for furniture, musical instrument, shoes industry, decoration, forestry industry and so on. Except of the following products, our company can produce varieties of the non-standard equipment for you, according to your demands. Principal features of HF hot press machine Simple operation, uniform heating, and prompt forming; Wooden mould adopted, low cost, simple replacement process to satisfy different requirements; Single HF can drive multiple presses; Small working area and low labor intensity; Environmental protective, no boiler, ash free and smog free. Applications Gule forming of the bentwood armrest, bentwood shelf, bed strips, unconventional teapoy, bamboo tread; glue forming of stereotypic seat-board, panel furniture headboard, box spring, surface of drawer, arc door; glue forming of chair-board & headboard for the children furniture; glue forming of various bentwood artware. Specifications:

workpiece processing: Manually Spread glue(or using glue spreader)-------put workpiece with glue into HF press ----start HF press -----Take out of the workpiece.

workpiece processing: Manually Spread glue(or using glue spreader)-------put workpiece with glue into HF press ----start HF press -----Take out of the workpiece.

High efficiency , one cycle only needs 2-5mins

High efficiency , one cycle only needs 2-5mins

if you have different shape workpieces to make, you only need to change the wooden mould, which is low cost , and help you increase your product diversity .

if you have different shape workpieces to make, you only need to change the wooden mould, which is low cost , and help you increase your product diversity . Related Keywords

Related Keywords