Automatic Sausage Making Machines

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 5-50 tons per day |

| Supply Ability: | 1 set per month |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,FCA,CPT,CIP |

| Certificate: | ISO9001-2008, CE |

| Transportation: | Ocean |

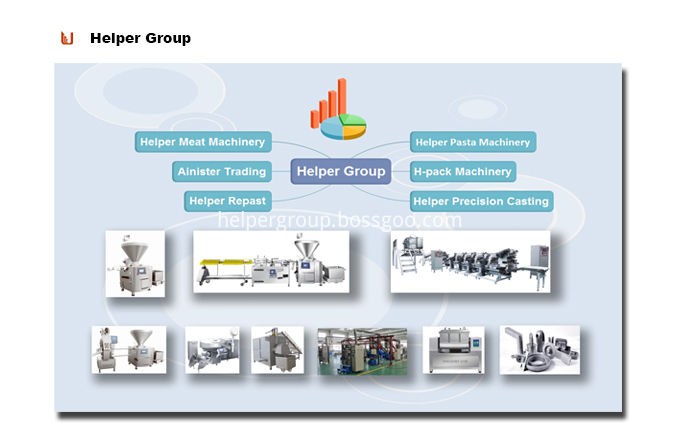

Helper Sausage Making Machines

We are a professional and one of the earliest and largest manufacturers of sausage making machines in China. We are providing our clients integrated and innovative solutions for different sausage products. Our automatic sausage making machines/production line include frozen meat cutting machine, frozen meat slicer, meat grinder, bowl cutter, meat mixer, vacuum meat tumbler, sausage filling machine, sausage clipping machine, high speed sausage twisting machine, smokehouse, meat cart, bin lifter, etc.

With years of sausage production experience, our sausage making machines are designed to streamline your sausage production process from raw material processing to packaging, providing a complete and efficient solution.

Our Automatic Sausage Making Machines are suitable for sausage production enterprises of all sizes, including small and medium-sized enterprises and large enterprises, producing various types and flavors of sausages to meet different market demands.

High performance, good quality and competitive price, all of these make our machines more and more popular among customers.

Video Display

Features of Helper Automatic Sausage Making Machine

- Full automation: Our Automatic Sausage Making Machines use the latest technology to automate the entire sausage production process, including raw material processing, mixing, filling, extrusion, cutting, baking, cooling, and packaging, reducing manual labor and increasing production efficiency and quality.

- Stability and reliability: Our machines are made with high-quality materials and components, undergo rigorous quality control and testing to ensure stability, reliability, and durability.

- Flexibility and diversity: Our sausage making machines are customizable and adjustable according to customer requirements, producing various types and flavors of sausages, such as hot dogs, sausages, German sausages, Italian sausages, Chinese sausages, and more, meeting different market demands.

- Environmental protection and energy-saving: Our Automatic Sausage Making Machines are designed with energy-saving and environmentally friendly technology, maximizing the reduction of energy and resource consumption, lowering production costs, and protecting the environment and health.

Production flow

Automatic Sausage Making Machines work by automating the sausage production process from raw material processing to packaging. Here's a general overview of how automatic sausage making machines work:

- Raw material processing: The raw materials, such as meat and seasonings, are prepared and processed, including grinding, mixing, and adding other ingredients.

- Filling: The prepared meat mixture is loaded into the filling hopper of the machine, which is then automatically transferred to the filling tube.

- Extrusion: The filling tube pushes the meat mixture through the extrusion nozzle, which shapes the meat mixture into the desired sausage shape.

- Cutting: The extruded sausages are cut into the desired lengths, either by a mechanical cutter or by using a wire system.

- Cooking/Baking: The sausages are cooked or baked at a specific temperature and time, depending on the recipe and sausage type.

- Cooling: The sausages are cooled down to a specific temperature, either through cold water or air cooling.

- Packaging: The cooled sausages are then packaged into various types of packaging, such as vacuum-sealed bags or casings, ready for sale.

Throughout the process, Automatic Sausage Making Machines are programmed to regulate and control the temperature, pressure, and speed to ensure consistent and high-quality sausages. Additionally, the machines can be customized to produce different types of sausages, such as hot dogs, sausages, German sausages, Italian sausages, Chinese sausages, and more, by changing the filling and shaping attachments.

Believing we will be your good partner by offering high qualtiy equipment, competitive price and excellent service.

|

|

|

Related Keywords