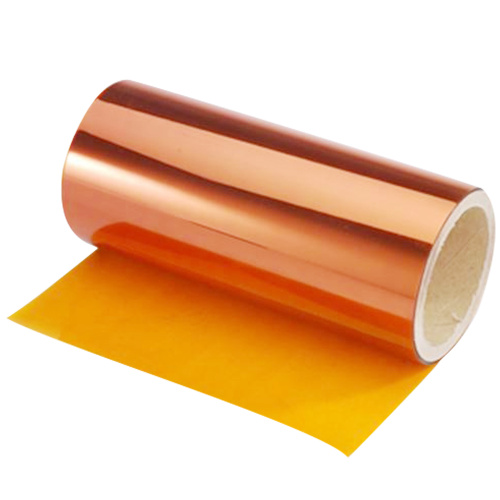

Amber Polyimide film for insulating circuit boards

-

$7.00≥1000 Square Meter

- Min. Order:

- 1000 Square Meter

- Min. Order:

- 1000 Square Meter

- Transportation:

- Ocean, Land, Air, Express, Others

- Port:

- Tianjin, Shanghai, Qingdao

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Productivity: | 10 ton per day |

| Supply Ability: | 100ton |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,FCA,CPT,CIP |

| Certificate: | CE,SGS |

| HS Code: | 3920999090 |

| Transportation: | Ocean,Land,Air,Express,Others |

| Port: | Tianjin,Shanghai,Qingdao |

Product Description

Product Description

Amber Polyimide film for insulating circuit boards

polyimide filmPolyimide film is a lightweight, flexible material that has excellent heat and chemical resistant properties. and polyimid is used in a wide variety of applications such as substrates for flexible printed circuits, transformer and capacitor insulation, sensors and bar code labels.

Features:

* High temperature resistance up to 260C

* Class H insulation

* Easy for processing

* Stable and flame retardant

Application

* Class H insulation

* Easy for processing

* Stable and flame retardant

Application

Aerospace - The polyimid film is converted and layered together to make multi-layer insulation.

Automotive / Industrial - Polyimide films have excellent mechanical, electrical, temperature and chemical resistance making them optimal for demanding industries where performance is critical or harsh exposure conditions exist.

Electronics - Polyimide film is the optimal substrate for high temperature applications like the electronics industry.

Labeling - Polyimide film, with the right printable coating applied, makes an excellent choice for labels used in harsh environments.:

Technical Data Sheet

|

Item

|

Unit

|

Value

|

Test Value

|

Test Methods

|

|

Thickness

|

um

|

>7.5

|

|

|

|

Width

|

mm

|

<1550

|

|

|

|

Tensile strength Mpa

|

MD

|

>145

|

|

GB/T

|

|

|

TD

|

>140

|

|

1354.2-2009

|

|

elogation at break %

|

MD

|

>35

|

|

|

|

|

TD

|

>34

|

|

|

|

Shrinkage

|

MD

|

﹤-0.15~1.5

|

|

TPC -TM-650

|

|

|

TD

|

﹤-0.15~1.5

|

|

200℃,30min

|

|

Surface tension

|

dyne

|

>50

|

56

|

|

|

Frequency electrical

strength |

V/um

|

≥60

|

|

|

|

Surface resistivity

|

Ω

|

≥1.0*10¹³

|

3.3*10¹³

|

|

|

Volume resistivity

|

Ω.M

|

≥1.0*10¹³

|

|

GB/T

|

|

hygroscopicity

|

|

|

|

1354.2-2009

|

|

hygroscopicity

|

50Hz

|

≤4.0

|

3

|

|

|

dielectric loss factor

|

50Hz

|

≤4.0×10¯²

|

7.4×10¯²

|

|

|

Fire proof

|

/

|

VTM-0

|

VTM-0

|

UL-94

|

Note: The above technical information and data should be considered representative or typical only and should not be used for specification purposes.

Shelf life:

Product shelf life is 2 years from date of manufacture when stored at room temperature conditions (72°F [22°C] and 50% RH) in the products original packaging.

Avaliable size

Width:300mm-1500mm. (Can be Customized) Max width:1600mm ,if lenght longer than this ,price will be much more expensive.

Length: 1000m /1500m(Can be customized).

Custom Sizes: If you need customized sizes or die cut parts please feel free to contact us.

Company Information

We have been in plastic film line for more than 12 years and we have much experience in plastic film

of all different application. our main products are all kind of function film . main 4 seirers

a. hologram projection film

1.rear projection film 2. 45 degree hologram projection film

b.PET function film

1.PET color film 2. PET milky white film ,3white pet film 4. black PET film

5.coated PET film 6.UV coating PET film etc

Related Keywords

Related Keywords