Construction Material Aluminium Alloy Building Formwork System

- Payment Type:

- L/C, T/T, Western Union

- Incoterm:

- FOB, CFR, CIF

- Min. Order:

- 100 Square Meter

- Min. Order:

- 100 Square Meter

- Delivery Time:

- 20 Days

- Transportation:

- Ocean, Land, Air

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei China |

|---|---|

| Productivity: | 10000square meter per month |

| Supply Ability: | 10000square meter per month |

| Payment Type: | L/C,T/T,Western Union |

| Incoterm: | FOB,CFR,CIF |

| Certificate: | ISO, SGS, or as your request |

| Transportation: | Ocean,Land,Air |

Product Description

Product Description

Aluminum formwork system components include the walls, columns, beams, plates,templates and panel frames. Dedicated pin buckles are used to connect the templates. The template system can be dismantled at an early stage. Standard specification size of the wall template is 100mm - 450mm X 1800mm-2400mm. Standard specification size of the roof template is 600mm X 600mm - 1200mm with standard average weight of 23 kg/m.

Aluminum Formwork Panel Advantages (1---10)

1. Short construction.

- Aluminum formwork system is quick release system, a set of formwork for one floor, just need 4days. Improve the construction progress and save cost.

2. Turns more and good economic benefit .

- Formwork can be re-used over 300-500 times and still keeps high quality to finish forming concrete surface. Also the average cost of using in each time is low.

3. Lighter weight, Construction more easily, conveniently and effectively.

- The weight of aluminum formwork is around 20KG/m2. The whole assembly process could be finished without any machines assist. The workers just need a spanner and a hammer to assemble the whole system easily. 20-30 square meters per person per day can be installed.

4. Good stability, high bearing capacity.

- The formwork made of 6061-T6 aluminum alloy plate and aluminum alloy profile. The system formed to a frame structure after assembling, its load bearing capacity reach to 60KN/m2.

5. The wide scope of application.

- Used in reinforced concrete field: wall, floors, windows, post, beam, bridge, etc.

6. Little flat-fell seam, high precision. Good surface after dismantling.

- The concrete surface after dismantling. It would be a very high quality finishing. The concrete surface is flat, smooth. No need a heavy backing plaster. Effectively for plaster cost saving.

7. Independent support system & tidy.

- Spare parts included pins and wedges should be recycled. Work site would be a safety, clean and tidy environment. Supporting system construction is simple,convenience and clean. Contrast to traditional formwork systems, aluminum formwork system used less supporting rods, it leave more space for walking or materials transportation.

8. Standard, and Highly optimized for general use.

- Has more specifications. It is according to the project with different size be assembled. Reduce the cost.

9. High Recyclable Value

- Dimensions of most of the formworks which used in different structural drawings are the same. It means that when you have a new different project, 70%-80% formworks of the last project could be recycled. After formworks lost a value in usage, the aluminum material could be re-sold to the market with a high price.

10. Conform to the Low-Carbon Economic requirements

- All the materials in the formwork system are recyclable materials. Most countries have been set a rule to prohibit using wooden formworks due to environment protection. Aluminum formwork is the best substitution.

Comparison of Aluminum Formwork and Wood Formwork

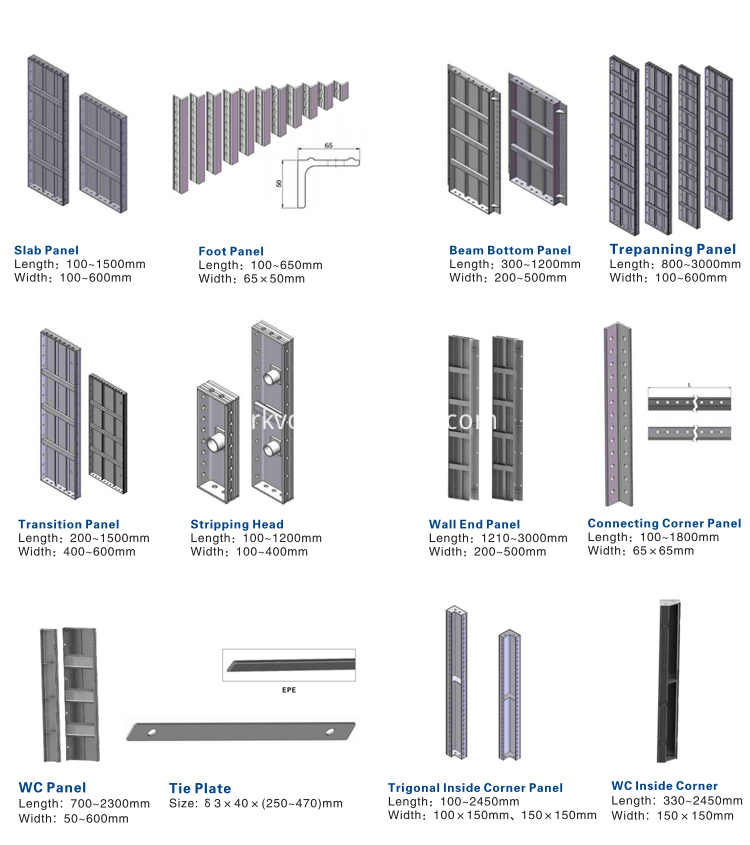

Component for Aluminum Formwork Panel

This Video Shows our Company History,pls check the link as below:

https://www.youtube.com/watch?v=h9n9Vydy7O0

Jointing formwork --- wall formwork--- beam forms---- stair formwork ---- concreting ---quality checking---- formwork-stripping

Welcome to inquiry about aluminum formwork system. Pls feel free to contact us. Thank you!

Related Keywords

Related Keywords