SUF36.5-780 corrugated steel panel roll forming machine

- Payment Type:

- L/C, T/T, Paypal, Money Gram, Western Union

- Incoterm:

- FOB, CFR, CIF, EXW, FCA, CPT, CIP

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 30 Days

- Transportation:

- Ocean

- Port:

- TIANJIN, XIAMEN

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|---|

| Productivity: | 500 SETS |

| Supply Ability: | 500 SETS |

| Payment Type: | L/C,T/T,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | ISO 9001 / CE |

| HS Code: | 84552210 |

| Transportation: | Ocean |

| Port: | TIANJIN,XIAMEN |

SUF36.5-780 corrugated steel panel roll forming machine

We put the steel sheet into the feeding part. The roll forming part will work under the motor power. The roller will bite the steel sheet , the sheet will feed into the machine along with the rotation of the roller. The panel enter into pressing part from forming part. The hydraulic cylinder will drive the mold of the pressing system up and down, it can press the color steel into shape of glazed tile. The cutting part can cut the steel tile into specific length.

Main features of 36.5-780 Corrugated Roofing Forming Machine

The advantages of Steel Panel Roll Forming Machine

1. The panel is widely used in modern factory, such as workshop, 4S auto shop, is a new popular roof panel and wall cladding

2. Easy operation, low maintenance cost.

Detailed Images of SUF36.5-780 corrugated steel panel roll forming machine

Machine parts

1. 36.5-780 Corrugated Roofing Forming Machine Rollers

Rollers manufactured by high quality 45# steel, CNC lathes, Heat Treatment, with Hard-Chrome Coating for long life,

With feeding material guide, Body frame made by 350H steel by welding

2. Corrugated Steel Panel Roll Forming Machine pre cut

Avoid wasting material, easy to operate, the precutter is connected with PLC control system,

PLC is calculating profile length within roll forming, once material is required to change,

PLC is calculating the length for total and remind operator, production finishes and able to manual shearing material before roll forming so as to change material for new production,

It is the advanced function and good for production to save material, no waste.

3. Steel Panel Roll Forming Machine Post Cutter

Cutter frame made by high quality 20mm teel plate by welding

Post cut, stop tp cut, use the same hydraulic mtor drive

Hydraulic motor: 3.7kw, Hydraulic pressure range:0 -12Mpa

Cutting tool material: mold steel Cr12, Heat Treatment

4. SUF36.5-780 corrugated steel panel roll forming machine PLC control system

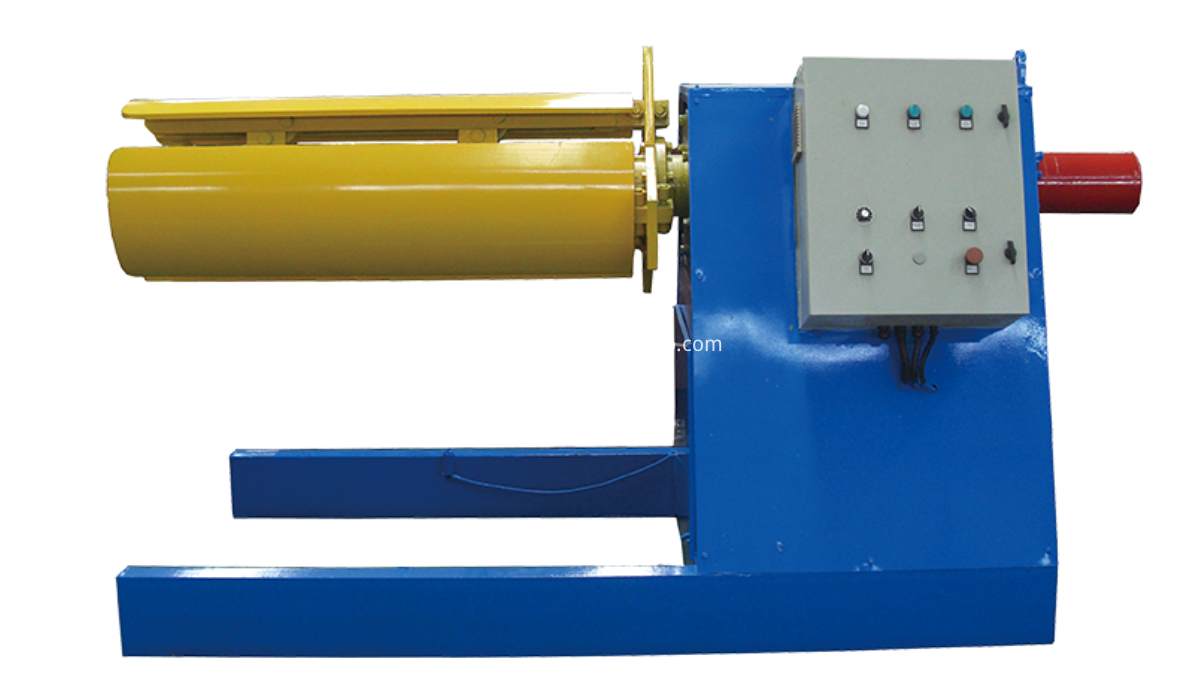

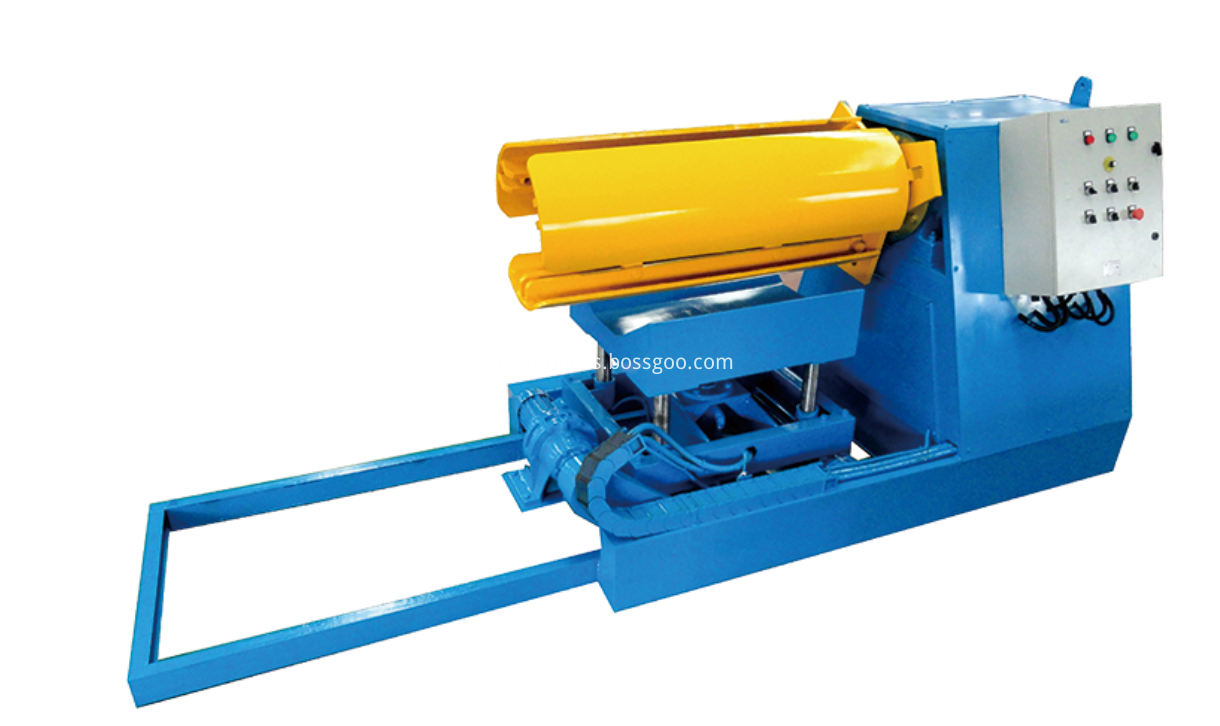

5. European Style Corrugated Roof Sheet Roll Forming Machine Decoiler

Manual decoiler: one set

Un-powered, manually control steel coil inner bore shrinkage and stop

Max feeding width: 1000mm, coil ID range 470±30mm

Capacity: Max 5 tons

with 6 tons hydraulic decoiler for option

Other dertails of Corrugated Roof Sheet Roll Forming Machine

Suitable for material with thickness 0.3-0.8mm,

Shafts manufactured by 45#, main shaft diameter 80mm, precision machine,

Motor driving, gear chain transmission, 19 rollers to form,

Motor driving 5.5kw, frequency speed control, forming speed pprox 15-20m/min.

Related Keywords