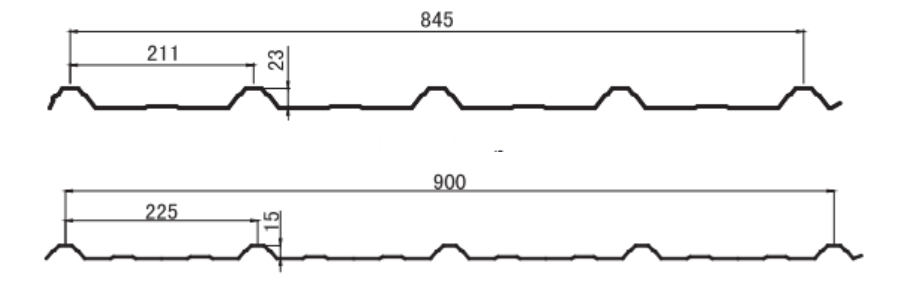

Maquina IBR doble capa laminas para techos 845/900

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB, CFR, CIF, EXW, FCA, CPT, CIP

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 30 Days

- Transportation:

- Ocean, Land, Air, by train

- Port:

- TIANJIN, XIAMEN, Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|---|

| Productivity: | 500 SETS |

| Supply Ability: | 500 SETS |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | ISO 9001 / CE |

| HS Code: | 84552210 |

| Transportation: | Ocean,Land,Air,by train |

| Port: | TIANJIN,XIAMEN,Shanghai |

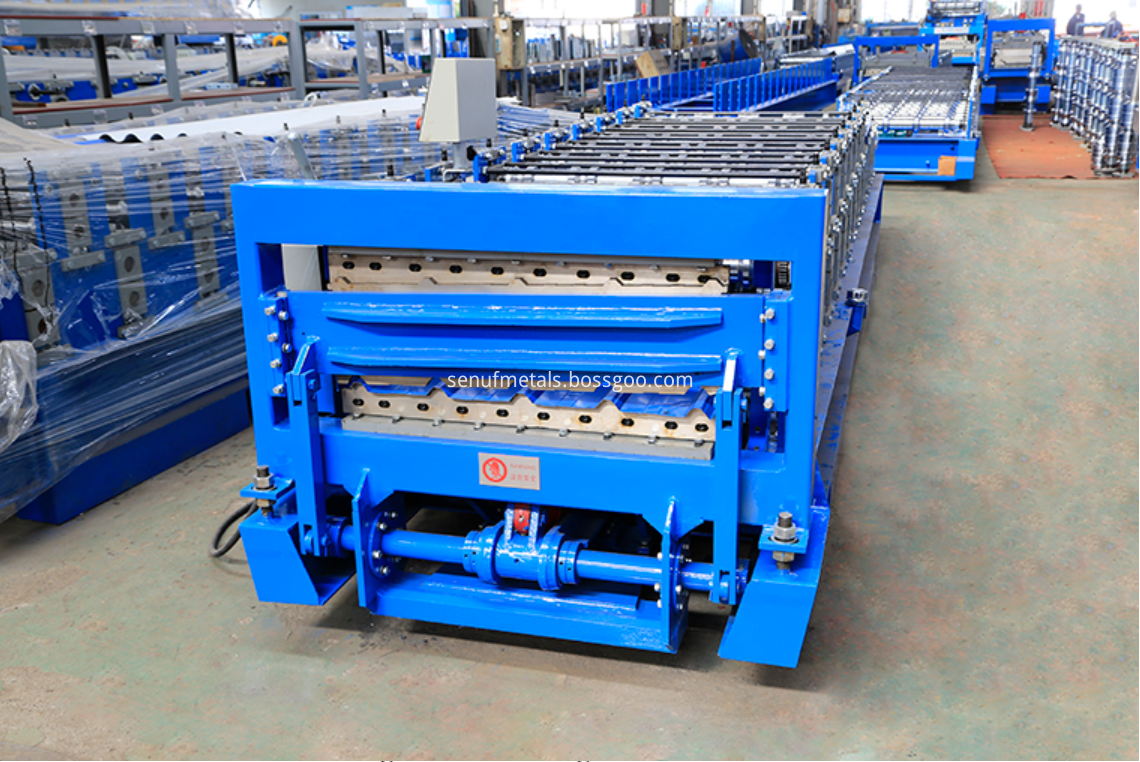

845&900 Roofing Sheet Double Layer IBR Corrugated Machine

Double Laye Roll Forming Machine and Corrugated Metal Sheet Making Machine is also called Steel Roof Tile Roll Forming Machine or Corrugated Metal Sheet Making Machine.It is a kind of machine which have two production lines for the roof sheet, the upper layer is one line, and the under layer is another line.But the two layers of Roofing Sheet Tile Roll Forming Machine or two lines can not product at the same time. Compared with two sets single layer machine, it can save space,money, just with one electric control desk and one hydraulic station, so it is easy to do the maintenance for workers.

Main features of 845&900 Roofing Sheet Double Layer IBR Corrugated Machine

The advantages of Double Laye Roll Forming Machine

1. Produce different roof panel size in one machine

2. Save space, more convenient,

3. Easy operation, low maintenance cost,

4. Stable and durable, sea freight for import can be saved by 50%

Detailed Images of 845&900 Roofing Sheet Double Layer Forming Machine

Machine parts

1. 845&900 Roofing Sheet Roll Forming Machine feeding guide

Make material feeding more smoothly and straight

2. 845&900 Roofing Sheet Roll Forming Machine rollers

Rollers are manufactured by high quality bearing steel Gcr15, CNC lathes, Heat Treatment, with black treatment or Hard-Chrome Coating for option, With feeding material guide, body frame made by 300#H type steel by welding

3. 845&900 Roofing Sheet Roll Forming Machine post cutter

Made by high quality mold steel Cr12 with heat treatment ,

Cutter frame made by high quality 25mm steel plate by welding

Hydraulic motor: 2.2kw, hydraulic pressure range: 0-16Mpa

4. 845&900 Roofing Sheet Roll Forming Machine Control System

Easy to operate

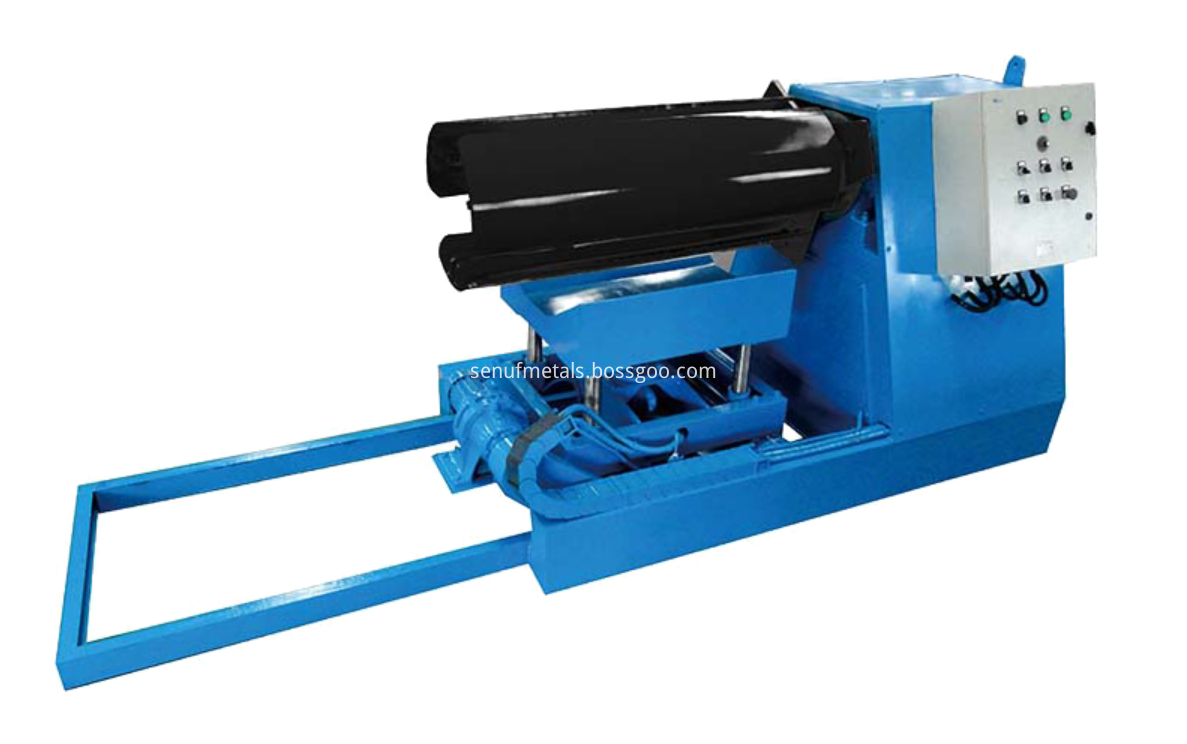

5. 845&900 Roofing Sheet Roll Forming Machine Decoiler

Manual decoiler: one set

Un-powered, manually control steel coil inner bore shrinkage and stop

Max feeding width: 1250mm, coil ID range 470±30mm,

Capacity: Max 8 ton

with 6 tons hydraulic as optional

6. 845&900 Roofing Sheet Roll Forming Machine exit rack

Un-powered, one unit

Other details of 845&900 Roofing Sheet Double Layer Roll Forming Machine

Suitable for material with thickness 0.3-0.8mm,

Shafts manufactured by 45#, main shaft diameter 75mm, precision machiend,

Motor driving, gear chain transmission, 14/9 forming stations,

Main motor 5.5kw, frequenct speed control, forming speed approx 12-15m/min

Related Keywords