Corrugated Metal Floor Deck Roll Forming Machine

- Incoterm:

- FOB, CFR, CIF, EXW, FCA, CPT, CIP

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 30 Days

- Transportation:

- Ocean

- Port:

- FUJIAN

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|---|

| Productivity: | 500 SETS |

| Supply Ability: | 500 SETS |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | ISO 9001 / CE |

| HS Code: | 84552210 |

| Transportation: | Ocean |

| Port: | FUJIAN |

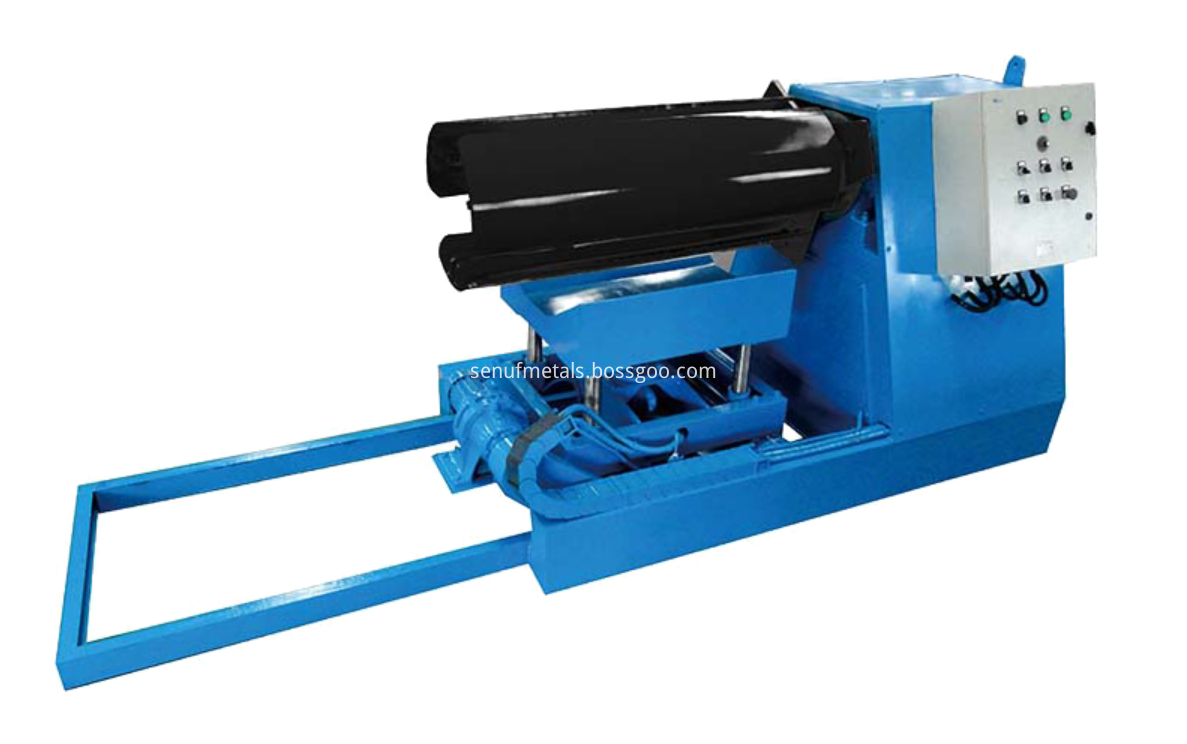

SUF 76-960 Corrugated Metal Floor Deck Roll Forming Machine

We provide an extensive line of products, including: roof and wall panel machine, tile roof machine, purlin forming machine, shutter door machine, floor decking machine and other associated equipment.

Our roll forming machines are equipped with PLC control to ensure high accuracy and easy operation.

Main feaures of Corrugated Floor Deck Forming Machine

The advanges of Metal Floor Deck Roll Forming Machine are asa follows:

1. The machine produced floor decking sheet have the features of low cost, light weight but high strength, short building period, and re-cycle use.

2. Save material, no waste,

3. Easy operation, low maintenace cost,

4. One machine for 3 models for optional (by changing spacer)

Detailed Images of SUF76-960 Metal Decking Forming Machine

Machine parts

1. SUF76-960 Corrugated Floor Deck Forming Machine manual pre-cutter

Brand: SUF, Original: China

Only for cutting the first piece and the end of piece of the sheet. For easy operation and save material: The precutter is conneted with PLC control system, PLC is calculating profile length with roll forming. Once material is required to change, PLC is calculating the length for total quantity and remid operator, production finishes and able to manual shearing material before roll forming so as to change material for new production. It is the advanced function and good for production to save material, no waste.

2. SUF76-960 Metal Decking Forming Machine

Rollers manufactured from high quality 45#steel, CNC lathes, Heat Treatment. with Hard-Chrome Coating for long working life.

Body frame made by 400H steel by welding, The material for embossing roller: bearing steel GCR15, heat treatment.

3. SUF76-960 Metal Floor Deck Roll Forming Machine post-cutter

Made by high quality mold steel Cr12 with heat treatment,

Cutter frame made from high quality 20mm steel plate by welding,

Hydraulic motor: 5.5kw, Hydraulic pressure range: 0-16Mpa

4. SUF76-960 Metal Decking Forming Machine product sample

5. SUF76-960 Corrugated Floor Deck Forming Machine decoiler

Manual decoiler: one set

Un-powered, manually control steel coil inner bore shrinkage and stop

Max feeding width: 1200mm, coil ID range 508±30mm

Capacity: 5-9 ton

6. SUF76-960 Metal Decking Forming Machine

Un-powered, one unit

Other detailes of SUF76-960 Metal Floor Deck Roll Forming Machine

Suitable for material with thickness 0.8-1.5mm

Shaft manufactured from 45#, Main shaft diameter Φ90mm, precision machined

Motor driving, gear chain transmission, 22 steps to form,

Main motor 18.5kw, Frequency speed control, Forming speed approx 12-15m/min

PLC control system (Touch screen brand: German Schneider Electric/Taiwan WEINVIEW, Inverter brand: Taiwan Delta, Encoder brand: Omron)

Combined with: PLC, Inverter, TouchScreen, Encoder, etc,

Cut-to-length tolerance≤±2mm,

Control voltage: 24V

User's manual: English

Related Keywords