Gear box roof sheet roll forming machine

- Payment Type:

- L/C, T/T, Paypal, Money Gram, Western Union

- Incoterm:

- FOB, CFR, CIF, EXW, FCA, CPT, CIP

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 30 Days

- Transportation:

- Ocean

- Port:

- Tianjin

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 500 sets / year |

| Supply Ability: | 500 sets / year |

| Payment Type: | L/C,T/T,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | ISO / CE |

| HS Code: | 84552210 |

| Transportation: | Ocean |

| Port: | Tianjin |

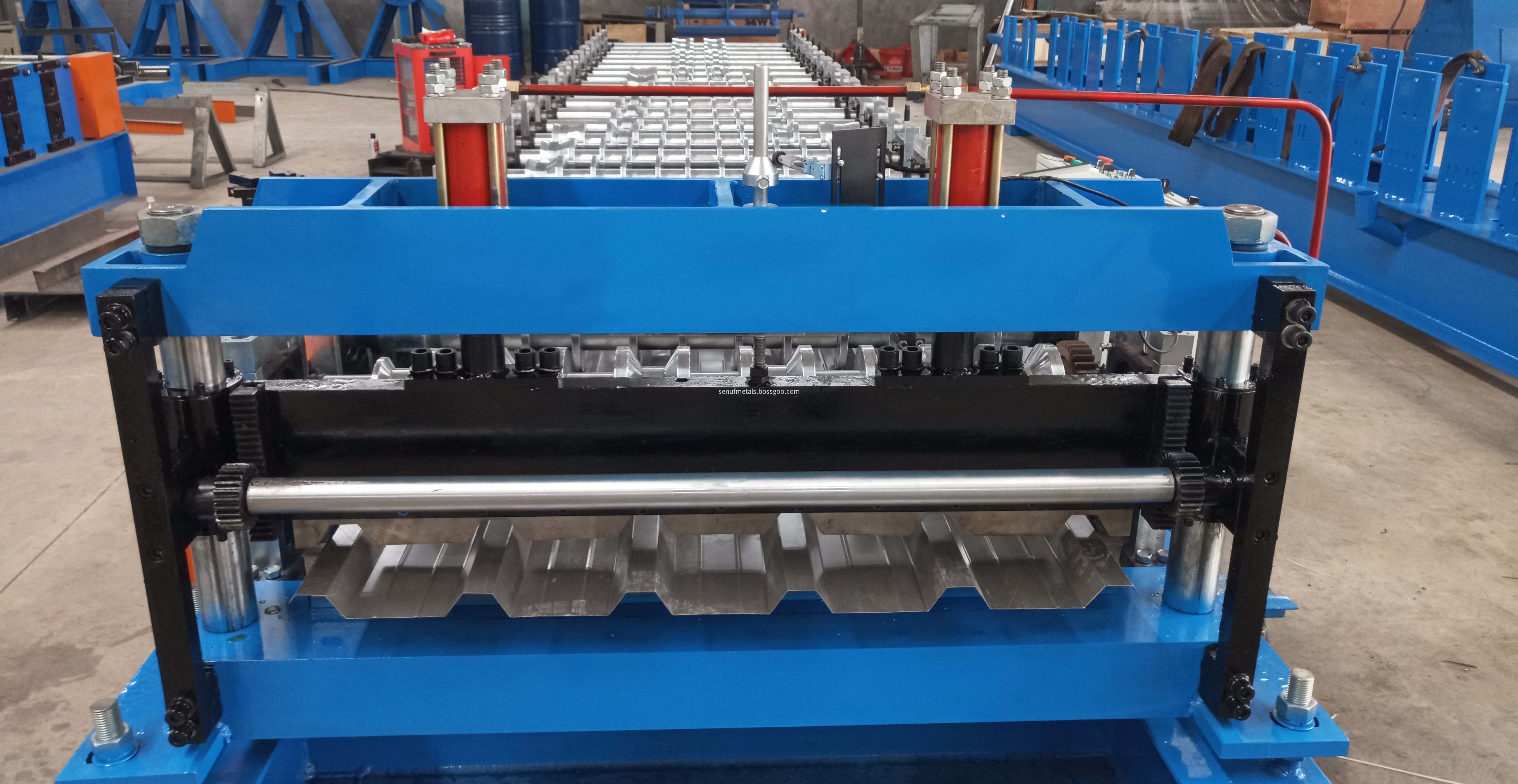

Gear Box Roof Sheet Roll Forming Machine

We are among the leading names in industry, engaged in Producing an exclusive range of Gear Box Roof Sheet Roll Forming Machine. We have developed High speed Roof Sheet Roll Forming Machine as per the industry standards. Owing to Gear box Roll Forming Machine easy manufacturing process, excellent performance and effective solutions, Metal High quality Roof Sheet Roll Forming Machines are widely appreciated.

Components:

5 Tons Hydraulic Decoiler

Leveling

Main Roll Forming

Hydraulic station

PLC Control system

Hydraulic cutting

Receving table

Technical parameters:

1. Raw materials: Galvanized coils, Pre-painted coils, Aluminum coils

2. Material thickness range: 0.35-0.8mm

3. Forming speed: 10-15m/min

4. Rollers: 16-20 rows(according to drawings)

5. Material of rollers: 45# steel with chromed

6. Shaft material and diameter: 75mm, material is 45#steel

7. Material of body: 400H steel

8. Wall panel: 20mm Q195 steel(all with electrostatic spraying)

9. Controlling system: PLC

10. Main power: 7.5KW

11. Material of cutting blade: Cr12 mould steel with quenched treatment

12. Voltage: 380V/3Phase/50Hz (customized)

13. Total weight: about 4 tons

5 Tons Hydraulic Decoilers:

Inner Diameter: 450-600mm

Outer Diameter: 1500mmCoil Width: 1300mm

Leveling:

Keep materials straight, and the width can be adjusted by manual.

Main Roll Forming:

1. Machine frame: 400H Steel

2. Transmission: Chain

3. Forming steps: 16-20 steps

4. Shaft Diameter: 75mm

5. Roller Material: 45# steel with chromed

6. Forming Speed: 10-15m/min

7. Motor: 7.5KW

Hydraulic station:

1. Power of the oil pump: 4kw

2. Hydraulic oil :40#

Control System: PLC

Brand: Delta

Language: Chinese and English (as required)

Function: Automatic control the cutting length and quantity, easy to operate and use.

Hydraulic cutting:

Cutter Material: Cr12 mould steel with quenched treatment

Cutting Tolerance: ±1.5mm

Related Keywords