STEEL STUB AND TRACK ROLL FORMING MACHINE

-

$1.00≥9000 Set/Sets

- Min. Order:

- 9000 Set/Sets

- Min. Order:

- 9000 Set/Sets

- Transportation:

- Ocean, Land, by train

- Port:

- XIAMEN, TIANJIN, Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|---|

| Productivity: | 500 SETS |

| Supply Ability: | 500 SETS |

| Payment Type: | L/C,T/T,D/P,Paypal,D/A |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP,DEQ,DDP,DDU,Express Delivery,DAF,DES,FAS |

| Certificate: | ISO 9001 / CE |

| HS Code: | 84552210 |

| Transportation: | Ocean,Land,by train |

| Port: | XIAMEN,TIANJIN,Shanghai |

SUF25-162-810 Glazed Tile Roll Forming Machine

The archaistic tile sheet is rolled and pressed by modular tile making machine, it has many features, such as good appearance, primitive simiplicity and elegance, unique style, noblest grade, and etc. It is widely used in garden style factories, scenic resorts, pavilions,hotels, villas, exhibition halls, country clubs, and so on for outdoor decorations.

Main features of Glazed Tile Roll Forming Machine

The advanages of SUF25-162-810 Glazed Tile Forming Machine are as follows:

1. Low cost, light weight but high strength, short building period, and re-cycle use,

2. Save material, no wadte,

3. Easy operation, low maintenance cost,

4. Infinite sizing (any size within machine range)

5. Optional punch hole at any position of purlin web side and flange size

Detailed images of SUF25-162-810 Glazed Tile Forming Machine

1. SUF25-162-810 Glazed Tile Forming Machine pre-cutter

with feeding guide

2. SUF25-162-810 Glazed Tile Forming Machine rollers

Rollers manfactured made by high quality 45# steel, CNC lathes, Heat Treatment,

with black treatment or Hard-Chrome Coating for options,

Body frame made by 350# H type steel by welding

3. SUF25-162-810 Glazed Tile Forming Machine punching mold

4. SUF25-162-810 Glazed Tile Forming Machine post cutter

Made by high quality mold steel Cr12 with eat treatment,

Cutter frame made by high quality 20mm steel plate by welding

Hydraulic motor: 5.5kw, Hydraulic pressure range: 0-16Mpa

5. SUF25-162-810 Glazed Tile Forming Machine products sample

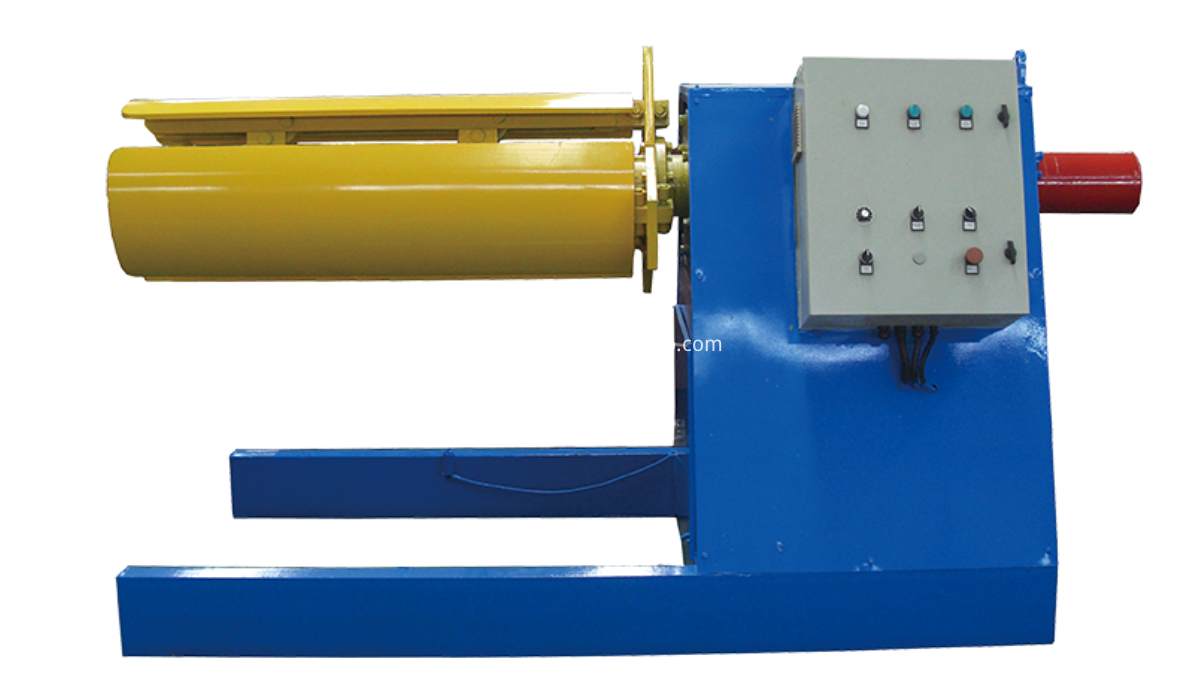

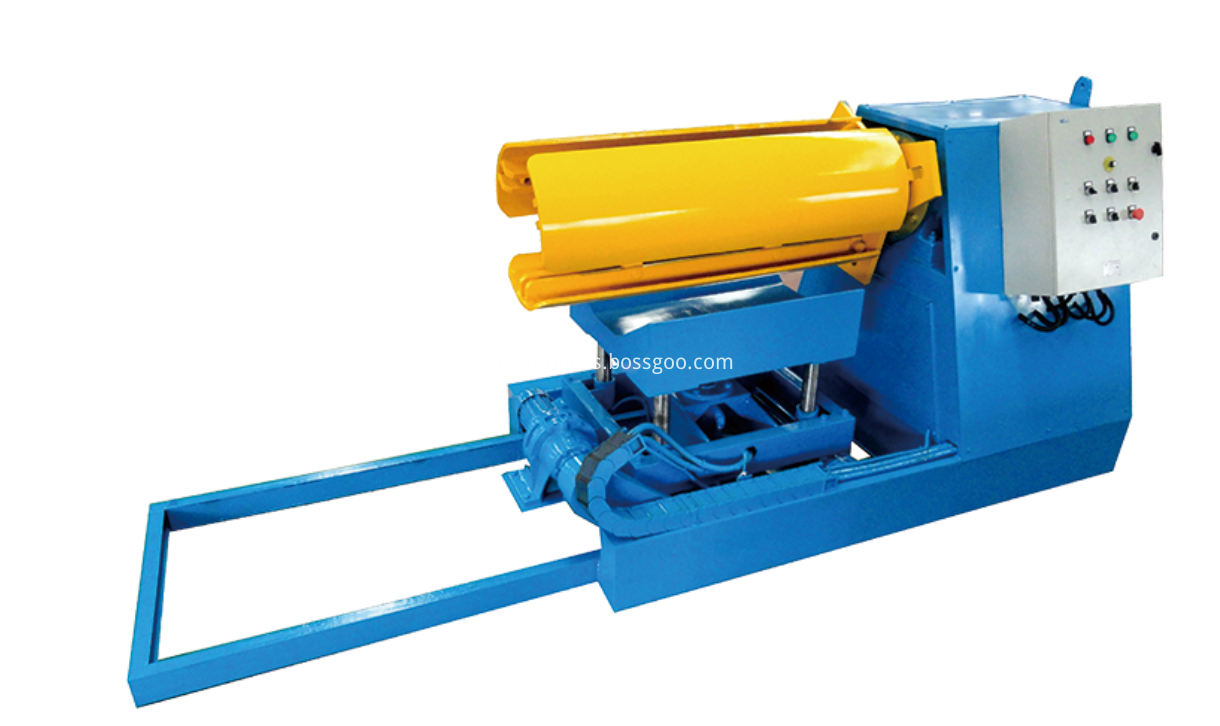

6. SUF25-162-810 Glazed Tile Forming Machine decoiler

Manual decoiler: one set

Un-powered, manually control steel coil inner bore shrinkage and stop

Max feeding width: 1200mm, coil ID range 508mm±30mm

Capacity: 5-9 tons

with 6 ton hydraulic decoiler for option

Other details of SUF25-162-810 Glazed Tile Forming Machine

Suitable for material with thickness 0.3-1.0mm

Shafts manufactured by 45#, Main shaft diameter 75mm, precision machined,

Motor driving, gear chain transmisson, 14 steps to form,

Main motor: 5.5kw, frequency speed control, forming speed approx 5-8m/min

Contact info: WhtasApp: +8615716889085

Related Keywords