Galvanized sheet roller shutter door slat forming machine

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB, CFR, CIF, EXW, FCA, CPT, CIP

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 30 Days

- Transportation:

- Ocean, Land, Air, by train

- Port:

- TIANJIN, XIAMEN, Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|---|

| Productivity: | 500 SETS |

| Supply Ability: | 500 SETS |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | ISO 9001 / CE |

| HS Code: | 84552210 |

| Transportation: | Ocean,Land,Air,by train |

| Port: | TIANJIN,XIAMEN,Shanghai |

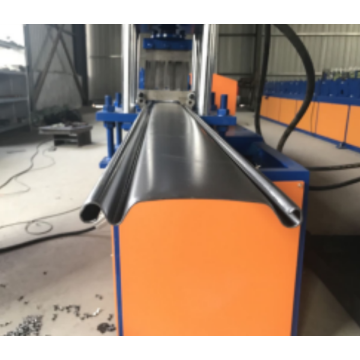

Galvanized Roller Shutter Door roll forming making machine

Main features of Roller Shutter Door roll forming making machine

The advantages of Galvanized Roller Shutter Door forming machine are as follows:

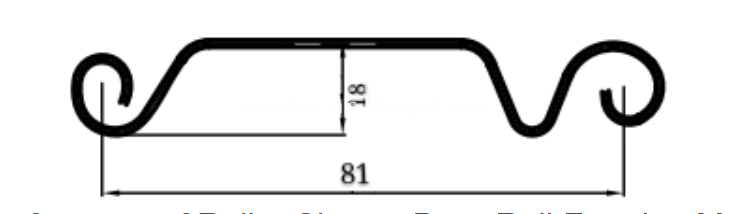

1. Three types of material thickness for options: 0.4-0.6mm for single phase power supply machine, 0.7-1.2mm even 1.5mm for 3 phase power supply machine,

2. Save space, more convenient,

3. Easy operation, low maintenance cost,

4. Stable and durable.

Detailed Images of Metal Roller Shutter Roll Forming Machine

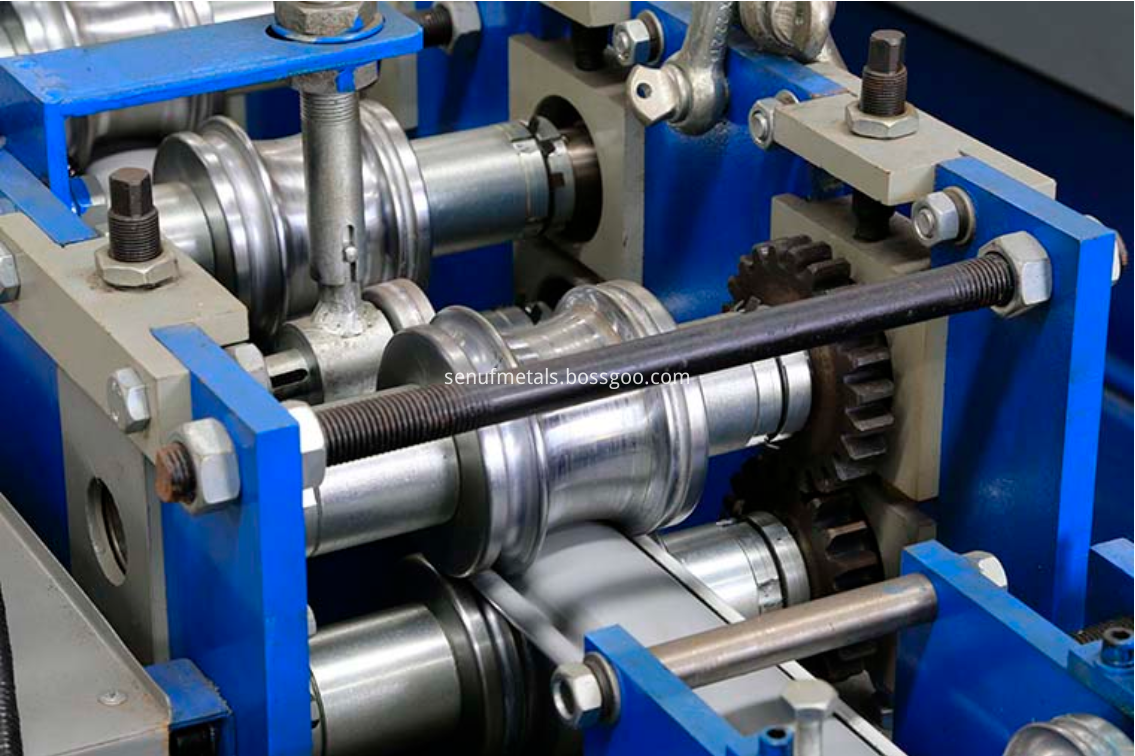

Machine parts

1. Galvanized Roller Shutter Door Forming Machine Guiding

2. Steel Metal Roller Shutter Sheet Roll Forming Machine Rollers

Rollers manufactured from high quality 45# steel, CNC lathes, Heat treatment, with black treatment or Hard-Chrome coating for options,

Body frame made by 300# H type steel by welding.

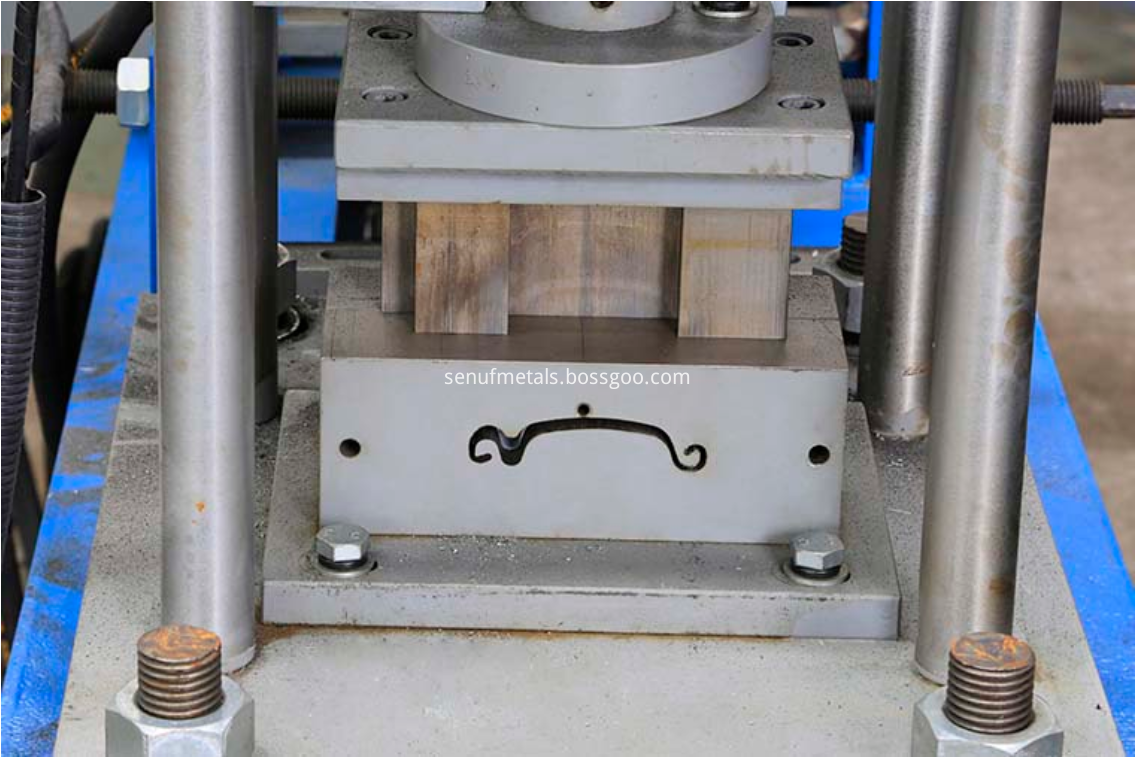

3. Roller Shutter Door Roll Forming Making Machine Cutter

Made by high quality mold steel Cr12 with heat treatment, cutter frame made by high quality 20mm steel plate by welding

4. Steel Roller Shutter Sheet Forming Machine PLC control system

5. Metal Roller Shutter Roll Forming Machine Decoiler

Manual Decoiler: one set

Un-powered, manually control steel coil inner bore shrinkage and stop,

Max feeding width: 300mm, coil ID range 470mm±30mm,

Capacity: 3 tons

6. Steel Metal Roller Shutter Sheet Roll Forming Machine Run-out table

Un-powered, one unit

Other details of Galvanized Roller Shutter Door roll forming making machine

Shafts manufactured by 45#, Main shaft diameter ⌀45/57mm, precision machined,

Motor driving, gear chain transmission, 14/19 steps to form,

Main motor: 4kw/5.5kw,

Frequency speed control, forming speed 12-15m/min.

PLC control system (Touch screen brand: German Schneider Electric / Taiwan WEINVIEW, Inveter brand: Taiwan Delta, Encoder brand: Japan Omron)

Related Keywords