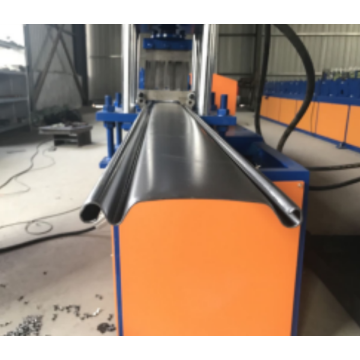

Automatic Shutter Door Forming Machine Equipment

-

$2000.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land, Air, by train

- Port:

- TIANJIN, XIAMEN, Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|---|

| Productivity: | 500 SETS |

| Supply Ability: | 500 SETS PER MONTH |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | ISO 9001 / CE |

| HS Code: | 84552210 |

| Transportation: | Ocean,Land,Air,by train |

| Port: | TIANJIN,XIAMEN,Shanghai |

Production Process:

Uncoiling→ Feeding material into machine →Roll forming → Auto cutting →Products receiving

Technical parameters:

|

Item Description: |

Material |

GI, PPGI, PPGL |

|

Width |

77mm.........................And So On |

|

|

Thickness |

0.3-0.6mm |

|

|

Yield strength |

Q195-Q235 |

|

|

Material of rollers |

High grade 45# forged steel, surface hard chromium plating |

|

|

Rows of rollers |

13-14 stations |

|

|

Material of shafts |

High grade 45# forged steel |

|

|

Diameter of shafts |

40mm |

|

|

Material of cutting blade |

Cr12 Heat Treatment |

|

|

Cutting Mode |

Hydraulic Guide Column |

|

|

Speed |

15-20m/min |

|

|

Side plate thickness |

16 mm |

|

|

Chain size |

1 inch Chain |

|

|

Total power |

4 kw |

|

|

Voltage |

380 V 50 HZ 3 Phase |

|

|

Length measurement |

Encoder |

|

|

Control mode |

PLC ---Delta Brand |

|

|

Operating mode |

Button + Touch screen |

|

Standard Configuration:

|

5 tons Manual decoiler |

1 set |

|

Main roll forming machine |

1 set |

|

Hydraulic pump system |

1 set |

|

PLC control system |

1 set |

|

Receiving Table |

1 set |

|

Spare parts |

1 set |

● Computer control system(imported computer)

It adopts Delta PLC to control. The target piece`s length is adjustable and digit of it can be adjusted. Computed mode has two modes: automatic and manual one. The system is easy to operate and use.

PLC is Delata, Inverter is Delta, the other Electron component is Schneider.

● Manul Decoile can bear 7 tons

Usage:It is used to support the steel coil and uncoil it in a turnable way. The steel coil is uncoiled by hand.

Inner diameter: 450-508mm

Can bear the max width of the coil is 1300mm

Can bear the max tons is 7 tons

Size of it is 1700mmx1500mmx1000mm

Related Keywords