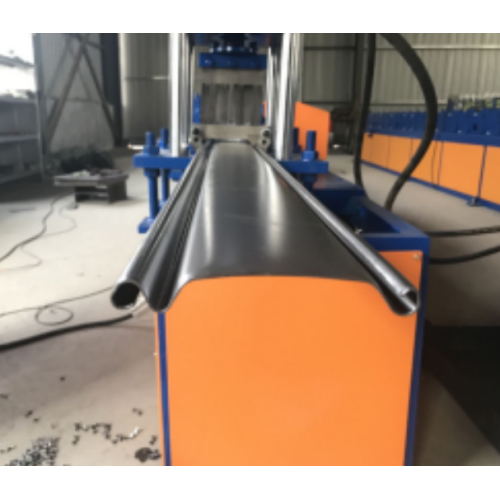

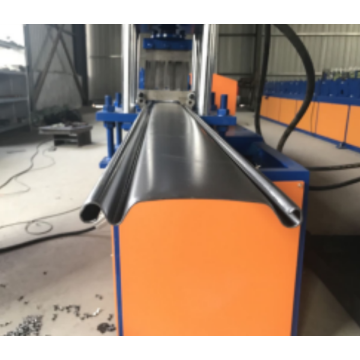

NEW SHUTTER DOOR ROLL FORMING MACHINE

-

$500.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land, Air, Express, Others

- Port:

- XINGANG, SHAGNHAI, QINGDAO

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|---|

| Productivity: | 100SETS ONE MONTH |

| Supply Ability: | 100 SET ONE MONTH |

| Payment Type: | L/C,T/T,D/P,Paypal,D/A,Others |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | ISO9001 |

| HS Code: | 84791100 |

| Transportation: | Ocean,Land,Air,Express,Others |

| Port: | XINGANG,SHAGNHAI,QINGDAO |

Technical parameter

|

material: GI |

|

|

Equipment operation |

Automatic |

|

Voltage |

380V 50HZ 3 Phases or as you requirment |

|

Thickness of sheet |

0.7-1.2mm |

|

Width of the material |

As Above |

|

After formed width |

As Above |

|

Dia of Roller Sahft |

50mm |

|

Rollers |

12pairs |

|

Productivity |

16-17m/min |

|

Dimension of main structure |

about 4000mm*650mm*1100mm |

|

Total power |

8.0kw |

|

Driven system |

4.0kw |

|

power of hydraulic system |

4.0kw |

Drawing of producing equipment

Equipment parts

● Manual Decoiler can bear 2 tons

Can bear the max width is 300mm

Can bear the max tons is 2 tons

Size is 1000mmx1000mmx1000mm

·Feeding platform

Put the raw material(steel plate) through the beach to manufacture and process, it can guarantee that the products are neat, parallel and everything is uniformity. Please refer to the equipment regulation to know the function of locate angle iron.

· Main Mould Parts

In order to keep the product shape and precision,motor reducer drive, gear transmission, roller surfaces polishing, hard plating , heat treatment and galvanizational treatment . The polished surface and the heat treatment towards the molds also can keep the molding plate surface smooth and not easy to be marked when it is being stamped.

Main power: 4.0kw(cycloidal planetary gear speed reducer)

·Automatic shearing system

It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products.

Material of blades: Cr12,quenching treatment

Components:It contains one set of cutting tools, one hydraulic tank and one cutter machine.

·Hydraulic system

It is controlled by gear wheel oil pump. After filling the hydraulic oil into the hydraulic oil tank ,the pump drive the cutter machine to begin the cutting job.

Components: The system includes a set of hydraulic tank , a set of hydraulic oil pump, two hydraulic pipes.and two sets of electromagnetism valves.

Power:4.0kw

·Computer control system

It adopts Delta PLC to control. The target piece`s length is adjustable and digit of it can be adjusted. Computed mode has two modes: automatic and manual one. The system is easy to operate and use.

·High-precision encounter

One counter gauges length, pulses, and decides length. Omron made in Japan.

Needed place and workmen

1) ground-level land

2) ≥5t overhead travelling crane

3) ≥-14℃ temperature in the working department

4) Space ofr storing material(4-5 different colors)

5) Space for laying the machine(at lease 27m*4m)

6) Road for vehicle moving

7) Workmen:2,operator and porter

Packing method

Nude, with waterproof cloth and stow-wood. Imported computer control system packed with waterproof cloth and card board.

Sales term

Buyers should pay 30% of the total payment in 7 days after signing <manufactured products purchase contract>. After finished production, we will inspect the machine and inform the buyer, the buyer send person to inspect goods, then payoff the whole payment before shipping out the goods. If the goods don’t accord with the standards, we will return all the advance payment.

After sales service

This producing line is maintained free of charge for 18 months. When the machine is used in China, we will install and debug the machine for free; if it is used at abroad, we will send the professional technician to debug. Buyers should take all the fees for technicians travelling abroad.

Manufactured days: 25 Days

Related Keywords