High speed cut-to-length machine line USA

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB, CFR, CIF, EXW, FCA, CPT, CIP

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 30 Days

- Transportation:

- Ocean, Land, Air, by train

- Port:

- XIAMEN, SHANGHAI, TIANJIN

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|---|

| Productivity: | 600 sets |

| Supply Ability: | 600 sets |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | ISO |

| HS Code: | 84552210 |

| Transportation: | Ocean,Land,Air,by train |

| Port: | XIAMEN,SHANGHAI,TIANJIN |

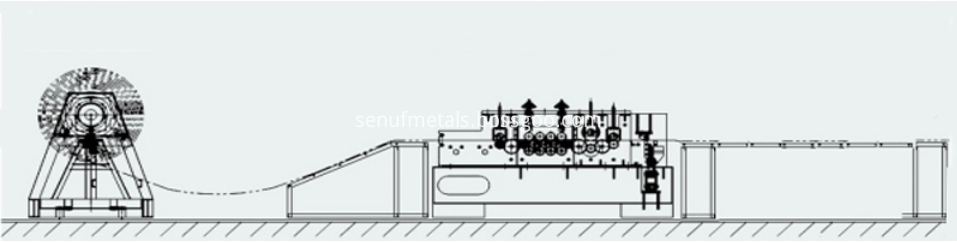

Automatic Cut-to-Length straightening machine

This machine is working for 1.0*1250mm aluminum metal coils, then the sheet after straightening and cutting can work with Glazed Tile Roof Sheet Roll Forming Machine, Corrugated Roof Sheet Roll Forming Machine, IBR Trapezoid Roof Sheet Roll Forming Machine, Floor Deck Roll Forming Machine and Hydraulic Guillotine Press Brake Machine and etc.

Features:

1. Automatic forming and cutting at any length with pre-cut,

2. Signal feedback from encoder showing length of product,

3. The control panel enables to count a total length of finished coil,

4. Rollers are alloy steel fabricated by CNC precision machine and hard chromium plated,

5. Cutting die is SKD11 steel fabricated by CNC machine, thermal treatment get 55-60HRC,

Working process:

Decoiler --- Feeding guide device --- Leveling device --- Slitting --- Hydraulic post cutting ---- Run out table

Machine Components:

1. Decoiler: 5*5 tons electric decoilers,

Max feeding width: 1250mm, coil ID range 508±30mm,

2. Main machine:

6 up+7 down,2 input totally 11 shafts for leveling function,

Body frame made by H400 type steel by welding,

Side wall thickness: 25mm, Q235,

Shafts manufactured by Gcr15 steel, diameter 85mm, high frequency, heat treatment,

Gear drive:

With Leveling function,

With Shearing function,

Speed: 16m/min,

Main machine motor power: 5.5kw+5.5kw,

With PLC control system,

3. Hydraulic cutting:

Post cut, stop to cutting, two pieces of cutting blades, no blanking,

Hydarulic power: 5.5kw, Cutting pressure: 0-21Mpa,

Cutting blade material: Cr12, with heat treatment HRC58-62°,

Cutting power is provided by the main engine hydraulic station,

4. Exit rack table:

Un-powered, one unit,

Packaging Style:

Packing method: main body of machine is naked and covered by plastic film (to prevent the dust and corrosion), loaded into container and steadily fixed in container suitable by steel rope and lock, suitable for long-distance transportation,

After-Sale Service:

1. The warranty is 12 months after the client receives the machines, within the 12 months, we will courier the replacement parts to the client for free,

2. We offer technical support for the entire life of our machines,

3. We can send our technicians to install and train the workers in the clients' factory.

Related Keywords