slitting line for metal steel coil shear and straighten

-

$45000.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land, Air, by train

- Port:

- XIAMEN, SHANGHAI, TIANJIN

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|---|

| Productivity: | 600 sets |

| Supply Ability: | 600 sets |

| Payment Type: | L/C,T/T,D/P,Paypal,D/A |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP,DEQ,DDP,DDU,FAS |

| Certificate: | ISO |

| HS Code: | 84552210 |

| Transportation: | Ocean,Land,Air,by train |

| Port: | XIAMEN,SHANGHAI,TIANJIN |

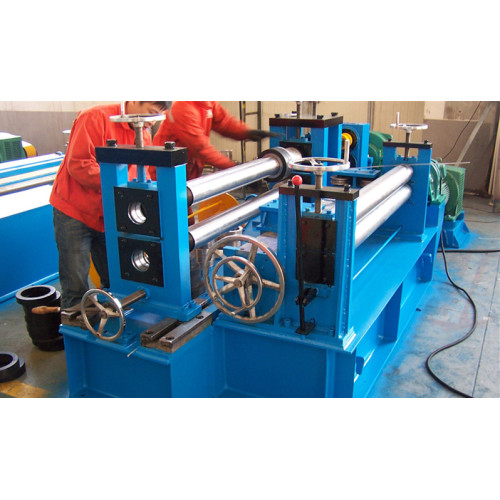

slitting line for metal steel coil shear and straighten

This machine is working for 3.0*1500mm metal coils, then the sheet after straightening and cutting can work with Glazed Tile Roof Sheet Roll Forming Machine, Corrugated Roof Sheet Roll Forming Machine, IBR Trapezoid Roof Sheet Roll Forming Machine, Floor Deck Roll Forming Machine and Hydraulic Guillotine Press Brake Machine and etc.

Features:

1. Automatic forming and cutting at any length with pre-cut,

2. Signal feedback from encoder showing length of product,

3. The control panel enables to count a total length of finished coil,

4. Rollers are alloy steel fabricated by CNC precision machine and hard chromium plated,

5. Cutting die is SKD11 steel fabricated by CNC machine, thermal treatment get 55-60HRC,

Working process:

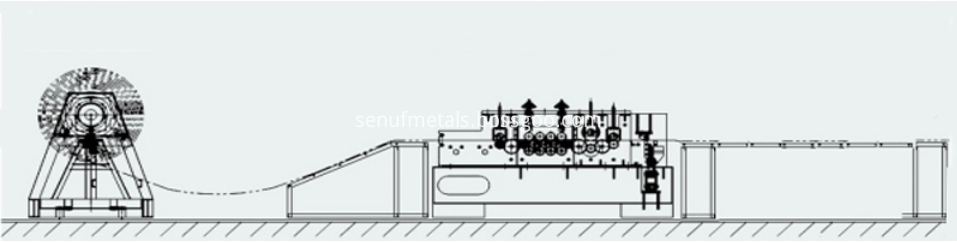

Decoiler --- Feeding guide device --- Leveling device --- Slitting --- Hydraulic post cutting ---- Run out table

Machine Components:

1. Hydraulic decoiler: one set

Hydraulic control steel coil inner bore shrinkage and stop,

Max feeding width: 1600mm, coil ID range 508±30mm,

Capacity: Max. 7 ton

2. Main machine:

Metal slitting line equipment mainly includes the following:

Loading trolley, double support uncoiler, feeding device, traction leveling machine, trimming shearing machine, deviation correction feeding device, longitudinal shear line, waste edge winder, feed rack, pre separation device, tensioner, feeding roller, winding shearing machine, steering drum, rear axle, discharge trolley, winding auxiliary support, hydraulic system and electrical system, etc.

The materials that can be processed by longitudinal shear equipment include cold-rolled plate, stainless steel plate, aluminum plate, galvanized plate and color coated plate. However, for different materials, there are certain differences in the strength of blade materials, so as to obtain good cutting effect.

Gear drive:

With Leveling function,

With Shearing function,

Speed: 25m/min,

Main machine motor power: 11kw+3.7kw,

With PLC control system,

Slit head:

Structure and type: Cassette type disc shear

Slitting shaft specification:Φ200x1350mm (blade position)

Slitting shaft material: 40 Cr, forging and tempering, mid-frequency quenching, hard chrome plating, grinding

Disc blade specification: D320xd200xT15mm

Disc blade material: 6CrW2Si, quenching hardness HRC58-600

Slitting power: DC 75kw with reduction box and universal joint

DC motor controller: Euro-therm controller

Slitting power: 2.2kw cylinder motor coordinate with worm and gear box

Blade replace type: hydraulic cylinder push rear cassette, cylinder specification: Φ63x450mm

Slitting speed: 0-120m/min adjustable

4. Exit rack table:

Un-powered, one unit,

Packaging Style:

Packing method: main body of machine is naked and covered by plastic film (to prevent the dust and corrosion), loaded into container and steadily fixed in container suitable by steel rope and lock, suitable for long-distance transportation,

After-Sale Service:

1. The warranty is 12 months after the client receives the machines, within the 12 months, we will courier the replacement parts to the client for free,

2. We offer technical support for the entire life of our machines,

3. We can send our technicians to install and train the workers in the clients' factory.

Related Keywords