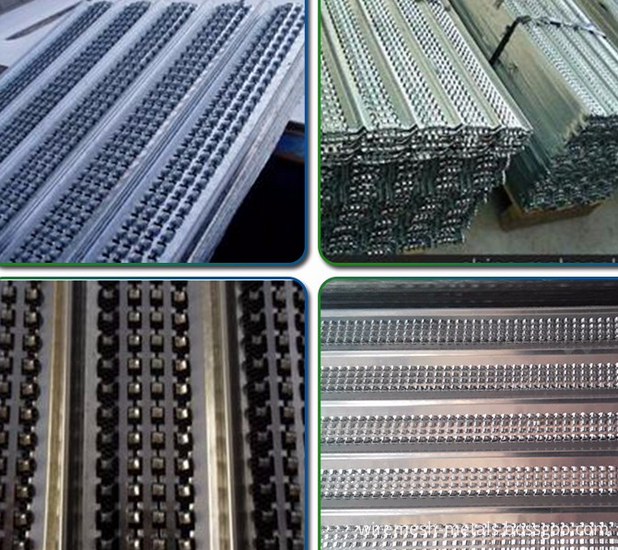

OEM Perforated Template Formwork hy Rib Mesh

- Payment Type:

- L/C, T/T, Western Union

- Incoterm:

- FOB, CFR, CIF

- Min. Order:

- 5 Ton

- Min. Order:

- 5 Ton

- Delivery Time:

- 25 Days

- Transportation:

- Ocean, Land, Air

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Hebei, China |

|---|---|

| Productivity: | 50000 tons/month |

| Supply Ability: | 50000 tons/month |

| Payment Type: | L/C,T/T,Western Union |

| Incoterm: | FOB,CFR,CIF |

| Certificate: | ISO9001, SGS |

| Transportation: | Ocean,Land,Air |

OEM Perforated Template Formwork hy Rib Mesh

HY-rib Lath is manufactured from hot dipped galvanized steel sheets.

Hy-rib lath is different from rib lath.

Hy rib lath is mostly used as concrete permanent dismantle free template for civil engineering such as tunnel, bridge,

raft style foundation, sewer system, subways, retaining wall, nuclear power station, docks, storang tanks,

skysrapers, ocean engineering and irregular or curved shapes.

Because its meshes and U patterns,

it has better anti-stress capability and forming flexibility than normal metal lath.

Hy rib lath has excellent engineering quality, construction security and widely used in tunnels bridges,

valve basement systems, sewage systems, subways, retaining walls, nuclear power plants, shipyards,

water pools and marine engineering works and high rise building projects and non-regular or bending pattern etc. as concrete permanent assembly-free formwork

Application of Galvanized Hy Rib Lath Panel

Widely used in tunnels bridges, valve basement systems, sewage systems, subways, retaining walls, nuclear power plants, shipyards, water pools and marine engineering works and high rise building projects and non-regular or bending pattern etc. As concrete permanent assembly-free form work.

Material of Hot Dipped Galvanized Hy Rib Lath Panel:

hot dipped galvanized steel plate,iron sheet,stainless steel panel,aluminum pieces.

Feature of Hot Dipped Galvanized Hy Rib Lath Panel:

(1) Mechanics performance is good, the lateral pressure is small.

(2)Optimization of process, increase the shearing interface

(3) Light weight, easy to transport and install.

(4) Easy to through and continuous banding steel bar.

(5)The bell socket and cutting easy operation.

| Material | Thickness(mm) | width(mm) | length(mm) | measurement(m2) |

| bright sheet | 0.1 | 450 | 2000 | 0.9 |

| bright sheet | 0.13 | 450 | 2000 | 0.9 |

| bright sheet | 0.15 | 450 | 2000 | 0.9 |

| Electro galvanizing | 0.1 | 450 | 2000 | 0.9 |

| Electro galvanizing | 0.13 | 450 | 2000 | 0.9 |

| Electro galvanizing | 0.15 | 450 | 2000 | 0.9 |

| hot galvanizing | 0.16 | 450 | 2000 | 0.9 |

| hot galvanizing | 0.2 | 450 | 2000 | 0.9 |

| hot galvanizing | 0.23 | 450 | 2000 | 0.9 |

| hot galvanizing | 0.25 | 450 | 2000 | 0.9 |

| hot galvanizing | 0.3 | 450 | 2000 | 0.9 |

| hot galvanizing | 0.35 | 450 | 2000 | 0.9 |

We also produce Expanded Sheet Metal Mesh, Expanded Metal Wire Mesh, Expanded Mesh and so on. Any inquiry, please let me know.

Related Keywords