Metal lows perforated sheet fence

- Payment Type:

- L/C, T/T, Western Union

- Incoterm:

- FOB, CFR, CIF

- Min. Order:

- 5 Ton

- Min. Order:

- 5 Ton

- Delivery Time:

- 25 Days

- Transportation:

- Ocean, Land, Air

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Hebei, China |

|---|---|

| Productivity: | 50000 tons/month |

| Supply Ability: | 50000 tons/month |

| Payment Type: | L/C,T/T,Western Union |

| Incoterm: | FOB,CFR,CIF |

| Certificate: | ISO9001, SGS |

| Transportation: | Ocean,Land,Air |

Metal lows perforated sheet fence

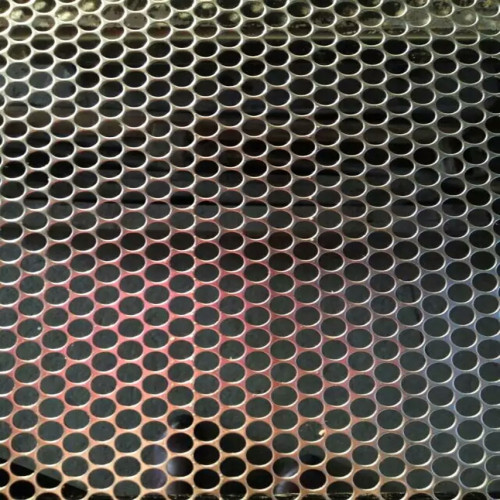

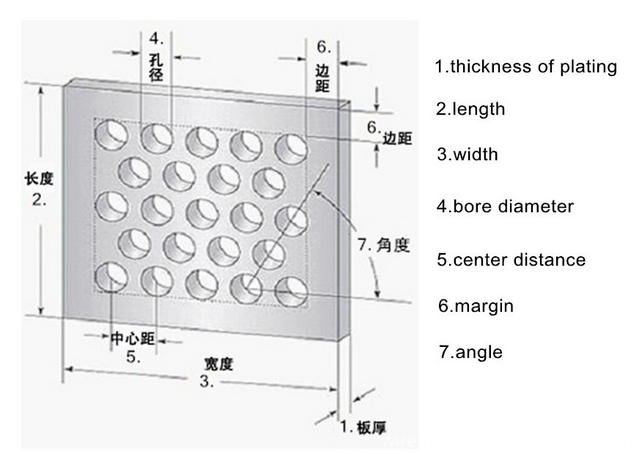

perforated sheet fence has thin thickness, material normally choose the stainless steel sheet, 304,316,etc.

Thickness from 0.5-0.8MM, the mesh can be packed by roll or by sheet.

| 1000mmX2000mm |

| 1220mmX2400mm |

| 1250mmX2500mm |

| 1250mmX6000mm |

| 1500mmX3000mm |

| 1500mmX6000mm |

However, we also manufacture other sheet sizes according to clients' requests.

4.Application: Perforated material is widely use as agriculture equipment, audio,automotive & transport, architecture, design, electronics, noise control, pharmaceutical, filtration, etc.

5 Production line

1)The first step is make product mould based on customer's requirements: punching process begins with precise mold design, mold quality largely determines the quality of the products.

2)The second step is choosing excellent material: galvanized steel,stainless steel,plain steel or others.

3)The third step is punching. we have advanced numerical control equipment, and can punch the high quality products

4)The fourth step is edge trimming. If the production process of plate edge is beyond the tolerance range of your requirements, our skilled technical personnel can according to your request help you eliminate redundant edges.

5)The fifth step is leveling. Leveling machine can help us restore its original level which are out of shape in the process of punching.

6)The sixth step is cleaning. To remove traces of its surface and make the perforatedd metal mesh clean.

Specifications:

| HOLE | CENTERS | OPEN AREA (%) | HOLES P.S.I. | SHEET SIZE | GAUGE |

| STEEL SHEET - STAGGERED HOLES | |||||

| 1/32 3/64 3/64 1/16 5/64 3/32 1/8 1/8 5/32 3/16 3/16 1/4 5/16 3/8 1/2 | 1/16 3/32 5/64 1/8 1/8 5/32 3/16 7/32 3/16 1/4 5/16 3/8 7/16 9/16 11/16 | 22 23 34 23 36 33 40 29 63 51 33 40 46 40 48 | 295 132 169 74 74 47 33 24 33 18 12 8 6 4 2 | 36" x 120" 36" & 48" x 120" 36" x 120" 36" & 48" x 120" 36" & 48" x 120" 36" & 48" x 120" 36" & 48" x 120" 36" & 48" x 120" 36" & 48" x 120" 36" & 48" x 120" 48" x 120" 36" & 48" x 120" 48" x 120" 36" & 48" x 120" 36" & 48" x 120" | 22 22 thru 18 24 22, 20, 18, 16 22, 20, 18, 16, 14 20, 18, 16, 14 24, 22, 20, 18, 16, 14, 12, 11 12 24, 22, 20, 18, 16 24, 22, 20, 18, 16, 14, 12 20, 16, 10, 3/16 20 thru 1/4 18 thru 14, 10 thru 1/4 20, 16, 14, 12, 11, 10, 3/16, 1/4 20, 16, 14, 11, 10, 3/16, 1/4 |

| STEEL SHEET - STRAIGHT HOLES | |||||

| 0.027 | 0.055 | 23 | 400 | 36" x 120" |

26 |

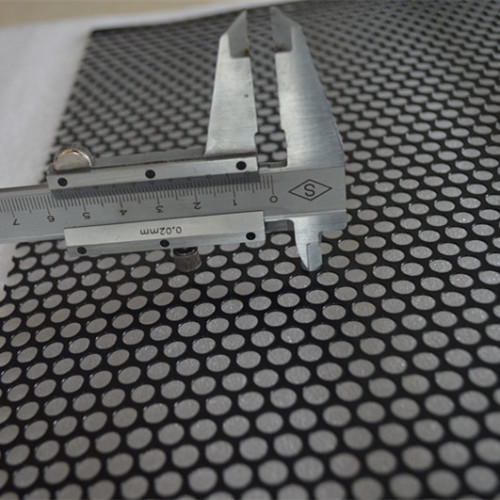

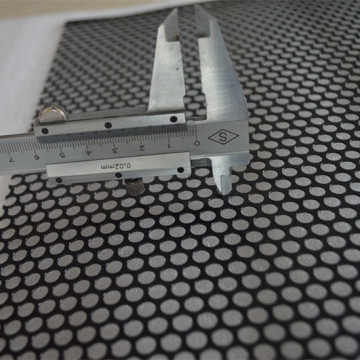

picture of Perforated Matal Mesh

Product Application:

Our machine:

Related Keywords