Neoprene/CR Rubber O Ring Seal

- Payment Type:

- L/C, T/T, Paypal, Western Union, WeChat

- Incoterm:

- FOB, CFR, CIF

- Min. Order:

- 100 Piece/Pieces

- Min. Order:

- 100 Piece/Pieces

- Delivery Time:

- 5 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Tianjin, Qingdao, Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 pcs/day |

| Supply Ability: | 10000 pcs/day |

| Payment Type: | L/C,T/T,Paypal,Western Union,WeChat |

| Incoterm: | FOB,CFR,CIF |

| Certificate: | ISO 9001/ISO/TS 16949 |

| HS Code: | 4016931000 |

| Transportation: | Ocean,Land,Air |

| Port: | Tianjin,Qingdao,Shanghai |

Neoprene/CR Rubber O Ring Seal

Rubber O Ring Mechanical Seal including Oil Resistant Mechanical Seal, Corrosion Mechanical Seal, Waterproof Mechanical Seal and so on.

CR rubber products:

Rubber has good elasticity after vulcanization, not afraid of the direct sunlight, there is a particularly good resistance to atmospheric aging performance, not afraid of intense distortion, not afraid of dichlorodifluoromethane and ammonia and other refrigerants, resistant to acid, resistant to silicon Lubricant, but not resistant to phosphoric acid ester hydraulic oil. It is easy to crystallize at low temperature, harden, and has poor storage stability, and is large in mineral oil with low aniline point. The general use of the temperature range of -50 ~ 150 ℃

Good elasticity and good compression deformation

Pre-sales

Many rubber material for you choose

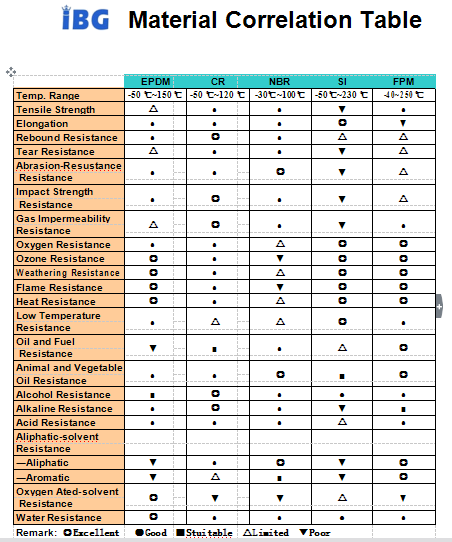

How to select the right material

*Drawings, photos and samples are welcomed.

Thanks for your view our products.

You are welcome to send inquiry to us. Must reply as soon as possible.

With anti-animal and vegetable oil characteristics

Not because of neutral chemicals, ester fat, grease, a variety of oil, solvent and affect the physical properties

With fire resistance

Disadvantages:

It is not recommended to use strong acids, nitrohydrocarbons, esters, chloroform and ketones.

Application areas:

Resistance to R12 refrigerant seals.

Suitable for the production of a variety of direct contact with the atmosphere, sunlight, ozone parts.

Applicable to all kinds of fire-resistant, chemical-resistant rubber products.

Solving problems and proposing sealing ways. Our engineers could offer design & selection support, and free sample could be provided for testing. IBG aim is solving sealing problems for global customers.

Middle-sales

To respect customers, service actively. Satisfying customers require-ments as our aim. Controlling product quality & delivery time strictly. 100% qualified.

After-sales

Tracking customers and replying questions positively. Answering problems patiently. If quality could not satisfy your request, return / exchange policy is available.

Butyl Excellent resistance to ketones, paint, ink dryers and ozones.

EPDM Excellent resistance to heat aging, ozone, acids, and alkalines.

Fluroelastomer (Viton) Excellent resistance to oils, fuels and solvents at higher temperature ranges.

Neoprene General industrial material used with non-aromatic petroleum oils and greases.

Nitrile ( Buna-N) (NBR) General industrial use material for oil, grease and solvent resistance.

Polyurethane (PU) Rubber like material with toughness and durability beyond the range of most rubber or plastics.

Silicone Excellent material for resistance to aging, heat, sunlight, many oils, and chemicals.

It's important to select the right rubber material for the applicaiton and the environment. Most rubber materials will have the flexibility to be used in rubber bellows applications - Beike Sealing. can work with you to identify the best, most cost effective material for your application.

1.What medium will contact when using, oil, chemicals...?

2.What is application temperature?

3.Dynamic seal or static seal?

4.Surface seal or shaft seal?

*We can produce the product according to your requirement or samples.

*Any questions or need more information, please feel free to contact with us.

*We are looking forward to have a good cooperation with you.

*welcome to visit our factory

1). Products in stock, delivery time is 1 workday;

2). Products out of stock, and mold in stock, delivery time is 5~7 workdays;

3). Products out of stock, and mold out of stock, delivery time is 10~15 workdays.

Remark: Delivery time is also subject to quantity.

Packaging Methods

Inner by the plastic bag, outer by the carton; or as the customer's demands.

SHIPPING TERMS

1). By Express ; 2). By Air; 3). By Sea.

Payment terms

Pay by Cash, Credit Card, T/T, Paypal and Western Union, all is welcome.

Related Keywords