Colored 75 Duro FKM O Ring viton gasket

- Payment Type:

- L/C, T/T, Paypal, Money Gram, Western Union

- Incoterm:

- FOB, CFR, CIF

- Min. Order:

- 200 Piece/Pieces

- Min. Order:

- 200 Piece/Pieces

- Delivery Time:

- 5 Days

- Transportation:

- Ocean, Land, Air

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 1000000pcs /month |

| Supply Ability: | long-term stability supply |

| Payment Type: | L/C,T/T,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF |

| Certificate: | ISO TS19649 |

| HS Code: | 4016931000 |

| Transportation: | Ocean,Land,Air |

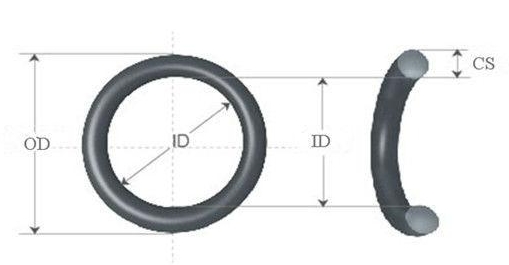

Colored 75 Duro FKM O Ring viton gasket

Operational application limits

Temperature EPDM 70: -45 °C to +130 °C

Temperature FKM: -15 °C to +200 °C

Temperature HNBR 70: -30 °C to +150 °C

Temperature NBR: -30 °C to +100 °C

Temperature VMQ 70: -55 °C to +200 °C

Application:non-flammability ,low gas permeability and excellent resistance to ozone,

weathering and aging. They can be used for extreme low temperatures and anti-explosion decompression applications: these rubber rings are manufactured with a very strong grade of FKM and are usually employed, respectively, in contact with e.g. liquid nitrogen and in petroleum extraction plants.

1) High performance

2) High Temperature

3) Oil Resistant

4) Plastic and Aluminum material

5) AS568 Standard and custom size

6)Black brown green color

FKM O Ring Photos

Packing and delivery

Date of Shipment :

1) 2-3 days if goods in stock

2) 5-7 days if goods out of stock with molding

3) 8-14 days if goods out of stock without molding

4) Store, Prompt shipment if annual requirement informed

Port of Loading:

Tianjin, Beijing or other Chinese port

Transport mode:

by air, sea, express mail, etc.

Term of payment

PayPal, Western Union, Money Gram, T/T in advance, L/C at sight, etc

Rubber material

EPDM

Good resistance to hot water and steam, detergents, caustic potash solutions, silicone oil and greases, many polar solvents, and many diluted acids and chemicals, along with a high level of ozone resistance. EPDM materials are totally unsuitable for use with all mineral oil products (lubricants, fuels).

FKM

Good chemical resistance to mineral oils and greases, synthetic oils and greases, engine, transmission and ATF oils to approx. +150°C, fuels, non-flammable hydraulic pressure fluids HFD, aliphatic, aromatic and chlorinated hydrocarbons, water to max. +80°C, excellent resistance to weathering, ozone and ageing, very low gas permeability (and therefore excellent for vacuum application) and resistance to a wide range of chemicals.

HNBR

HNBR is obtained by fully or partially hydrogenating NBR. It leads to considerable improvement in resistance to heat, ozone and ageing, and gives it very good mechanical properties, e.g. good resistance to wear. The media resistance compares to that of NBR. HNBR has a good resistance to some refrigerants. The temperature application range is from -30°C to +150°C.

NBR

Good chemical resistance to mineral oils and greases, hydraulic oils H, HL, HLP, non-inflammable hydraulic pressure fluids HFA, HFB, HFC to approx. +50°C and water to max. +80°C

VMQ

Good resistance to water (up to 100 °C), aliphatic engine and transmission oils, animal and plant oils and fats. VMQ is generally not resistant to fuels, aromatic mineral oils, steam (short term up to 120 °C possible), silicone oils and greases, acids and alkaline compounds.

Related Keywords