Oil Resistant Rubber Washer Gasket

- Payment Type:

- L/C, T/T, Paypal, Western Union

- Incoterm:

- FOB, CFR, CIF, FCA, EXW

- Min. Order:

- 100 Piece/Pieces

- Min. Order:

- 100 Piece/Pieces

- Delivery Time:

- 10 Days

- Transportation:

- Ocean, Land, Air, Express

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 100000pcs/week |

| Supply Ability: | 100000pcs/week |

| Payment Type: | L/C,T/T,Paypal,Western Union |

| Incoterm: | FOB,CFR,CIF,FCA,EXW |

| Certificate: | TS16949 |

| Transportation: | Ocean,Land,Air,Express |

Oil Resistant Rubber Washer Gasket

All rubber washers are precision mold pressing and are manufactured from elastomeric materials. The exact material that is best for your project needs depends entirely on the type of project, the temperatures the washer will be exposed to and the longevity expected from the device.

We offer rubber washers in the following materials:

According to gasket drawing or samples.

Rubber Gasket Material

NBR, SILICONE, EPDM, HNBR, FFKM, FKM, FVMQ, BUNA, CR...all is available. Flat washer gasket material is subject to real working conditon, including application temperature, medium contacting, uses...If you are not sure the material, pls kindly offer working condition, we will help suggest.

Different Material Application Temperature, see below,

- NBR: from -25~100 degree

- FKM: from -15~200 degree

- EPDM: from -55~150 degree

- SILICONE: from -60~230 degree

- CR: from -40~120 degree

- FFKM: from -15~300 degree

-

HNBR: from -40~150 degree

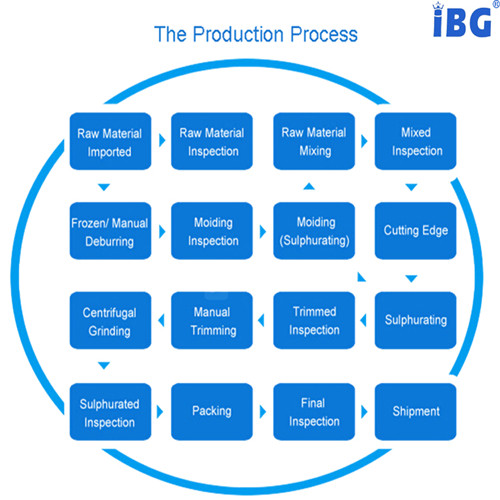

Progress Flow Chart

a. Material inspection: Testing for all raw materials before storage, and provide the raw material of relevant reports, report and raw material properties with comparison, two of reported values, can storage.

b. Mold Inspection: Die Mold development finished or after cleaning ,we will check the full size of the mold ,ensure quality for each cavity's product.

c. Product Inspection: During production ,Inspectors will check semi-finished products , ensure product process and make the defective rate control in a reasonable range.

d. Quality Control: Quality Department will check product appearance for each batch.

e. Product Full Inspection: Optical Sorting Machine ensure products appearance ,Size 100% qualified.

Related Keywords