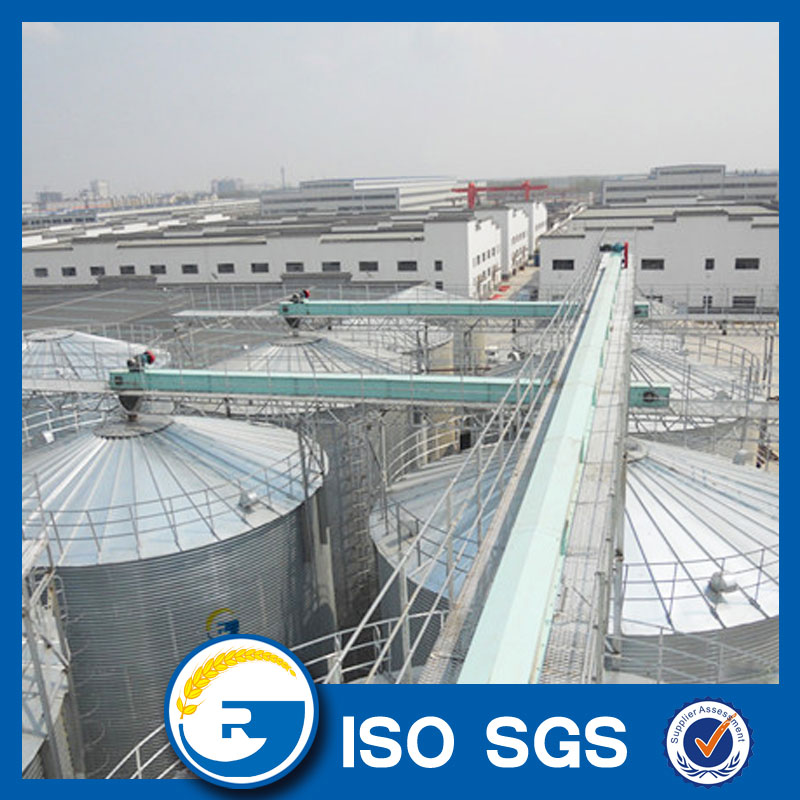

1000 MT Vertical storage steel silo for grain

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB, CFR, CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 30 Days

- Transportation:

- Ocean

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 1000 tons silo |

| Supply Ability: | 50 sets / year |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF |

| Certificate: | ISO BV |

| Transportation: | Ocean |

1000 MT Vertical storage silo steel silo for grain

For the 1000 tons silo, we have two design : flat bottom silo and Hopper bottom silo , here we introduce another bottom : Hopper bottom silo

Technical Parameters :

Silo bottom: Hopper bottom silo

Silo capacity: 1000 tonnes steel silo

Diameter: 11 meter

Silo Volume: 1428 CBM

Auxiliary System:

1. Ventilation System

2. Temperature Sensor System

3. Fumigation System

4. Thermal Insulation System

Discharge: scraper conveyor

Silo is Hot-galvanized steel sheets bolted , From top to Bottom .

Wall sheets:

Wall Sheets are connected together with high strength bolts to establish the ring of the silos.

wall sheets are in 275gr/m2 standarts . This difference not only prolongs the life of the coating,

but also provides protection against external factors.

What is the processing steps for the steel silo wall sheets ?

Silo each part description :

1. Catwalk on the Silo Top:

Safety constructions are recommended to be used in complete grains storage systems.

These constructions are elevator towers, catwalks and catwalk supports.

All can be produced both painted and galvanized according to customer's request.

2. Steel Storage silo Roof :

Roof is made up of radiated beam, roof cover board, tension ring, ventilator scoop, roof cap, etc.

The space age construction technology, which is adopted in the design of the silo framework,

can ensure the stability of silo under the large span. There is a guardrail around the silo

eaves and there is also a manhole on top of the roof.

3.. 1000 tons steel silo for grain bottom :

--------Hopper bottom / Conical bottom :

Hopper silos lower part has 45° and 60° degree angle and this allows the

grain to flow easily with its own fluidity.

Related Keywords