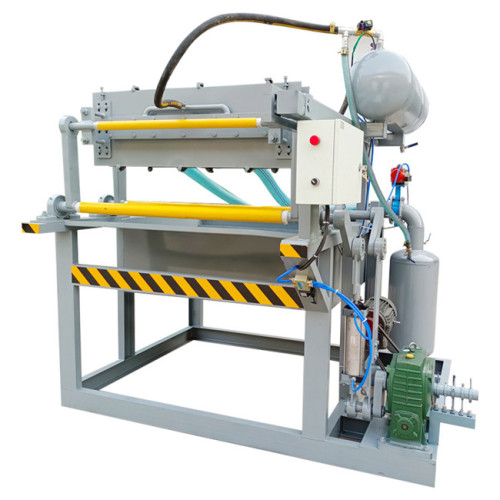

egg tray pulp molding machine

-

USD2000≥5000 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land

- Port:

- Shanghai, Tianjin, Qingdao

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 5-10 set per month |

|---|---|

| HS Code: | 84413010 |

| Transportation: | Ocean,Land |

| Port: | Shanghai,Tianjin,Qingdao |

In 2010, HUATAO began to get involved in the field of pulp molding equipment. While closely following the trend of green environmental protection and low energy consumption, HUATAO is not only committed to manufacturing and selling pulp molding machines with diverse output, stable performance and reasonable price, but also helping them turn waste paper into wealth.

HUATAO equipment is sold on a turnkey basis, with each factory individually customized to the customer's specific circumstances. Whether it is egg trays or other equivalent pulp molded products, HUATAO is always committed to providing the most efficient and affordable solutions for your production line, from pulping system to forming to drying.

What is a egg tray pulp molding machine ?

APulp Molding Egg Tray Production Line is a type of equipment used to manufacture products made from pulp, typically derived from recycled paper or agricultural fibers. It is commonly used to produce packaging items such as egg trays, fruit trays, cup holders, and other molded pulp products.

How does a egg tray pulp molding machine?

The working principle of aPulp Molding Egg Tray Production Line involves several steps:

Pulping: Waste paper or other fibrous materials are mixed with water and broken down into a pulp consistency.

Forming: The pulp is placed into molds or formers that have the desired shape of the final product.

Drying: Excess water is removed from the formed pulp by applying heat or using a drying system.

Demolding: The dried molded pulp product is released from the molds or formers.

Finishing: Additional trimming, stacking, and packaging may be carried out to prepare the final product for shipping.

what's type of egg tray pulp molding machine drying section we can offer ?

Natural drying system requires labor force but saves equipment costs. When your productivity is small, like 1000 pieces output per hour, you can choose to dry egg tray under the sun. Certainly, suitable temperature and wind should be guaranteed.

Semi-automatic drying system needs few people to operate, so it relatively saves the cost. When your paper egg tray making machine is small or medium, you are supposed to choose the semi-automatic dryer. Workers use small car to convey paper egg tray to drying room. Compared with natural drying system, this drying system can dry more egg trays per hour. it is suitable for semi automatic egg tray machine.

Automatic drying system offers automatic assembly line and doesn’t need extra people to work, which is easy to operate and manage. When the productivity is medium or large, you can select the automatic dryer. This dryer has simple installation, multi-layer structure and reasonable price. And we always use natural gas or diesel oil as dryer’ fuels. You can choose the suitable one according to your requirement. It is a good choice for automatic egg tray machine.

Whether you need help with equipment selection, process optimization, or design customization, our team can help. We have the expertise and knowledge to analyze your project needs, identify challenges and develop innovative solutions.

Related Keywords