Semi-automatic egg pulp tray forming machine

-

USD30000≥5000 Set/Sets

- Min. Order:

- 5000 Set/Sets

- Min. Order:

- 5000 Set/Sets

- Transportation:

- Ocean, Land

- Port:

- Shanghai, Tianjin, Qingdao

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Supply Ability: | 5-10 set per month |

| HS Code: | 84413010 |

| Transportation: | Ocean,Land |

| Port: | Shanghai,Tianjin,Qingdao |

Semi-automatic egg pulp tray forming machine

Usage for Semi Automatic egg pulp tray forming machine/Egg Tray Molding Machine

A semi-automatic egg pulp tray forming machine is a type of equipment used to produce egg trays or egg cartons from pulp material. While the machine performs many of the processes automatically, some manual intervention and operator control are required. Here's a general overview of how a semi-automatic egg pulp tray forming machine is used:

1. Pulp Preparation: The first step is to prepare the pulp material. This typically involves shredding or pulping waste paper, such as newspapers or cardboard, and mixing it with water to create a pulp mixture. The pulp is then screened to remove impurities and achieve the desired consistency.

2. Pulp Delivery: The prepared pulp mixture is transferred to a pulp storage tank or container located near the forming machine. The machine may have an integrated pulp delivery system or require manual loading of the pulp into the machine's hopper.

3. Mold Preparation: The machine is equipped with molds that determine the shape and size of the egg trays. The operator selects the appropriate mold based on the desired tray configuration (e.g., number of egg slots, tray dimensions). The mold is installed and secured in the machine.

4. Machine Setup: The operator sets up the machine by adjusting various parameters, such as pulp consistency, vacuum strength, and forming time. These settings may vary depending on the specific machine model and the quality requirements of the egg trays.

5. Tray Forming Process: The operator initiates the forming process by activating the machine. The machine uses a vacuum system to draw the pulp mixture onto the mold surface. The pulp is then pressed against the mold to shape it into the desired tray configuration. Excess water is drained or extracted during this process.

6. Tray Drying: After the trays are formed, they need to be dried to remove moisture and solidify their structure. The semi-automatic machine may have a built-in drying function, such as a heating element or hot air circulation, or it may require manual transfer of the trays to a separate drying area or drying racks.

7. Tray Removal: Once the trays are dry and sufficiently hardened, they can be removed from the molds. The operator manually removes the formed trays from the machine, taking care not to damage or deform them.

8. Quality Control: The operator inspects the formed trays for any defects, such as misshapen slots or weak areas. Any defective trays are discarded or manually corrected. Quality control checks may include visual inspection, dimensional accuracy verification, and tray strength testing.

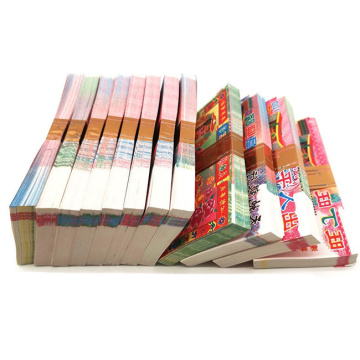

9. Stacking and Packaging: The formed and inspected trays are stacked and packaged for storage or transportation. Stacking machines or manual stacking methods may be used to organize the trays into bundles or pallets. Packaging materials, such as shrink wrap or corrugated boxes, are used to protect and secure the stacked trays.

It's important to note that the specific operation and features of a semi-automatic egg pulp tray forming machine Egg Tray Molding Machine may vary depending on the manufacturer and machine model. Operators should follow the machine's user manual and safety guidelines provided by the manufacturer for proper usage and maintenance.

Related Keywords