Poultry egg tray making machine

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land, Air

- Port:

- Shanghai, Tianjin, Qingdao

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 5-10 set per month |

| Supply Ability: | 5-10 set per month |

| HS Code: | 84413010 |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai,Tianjin,Qingdao |

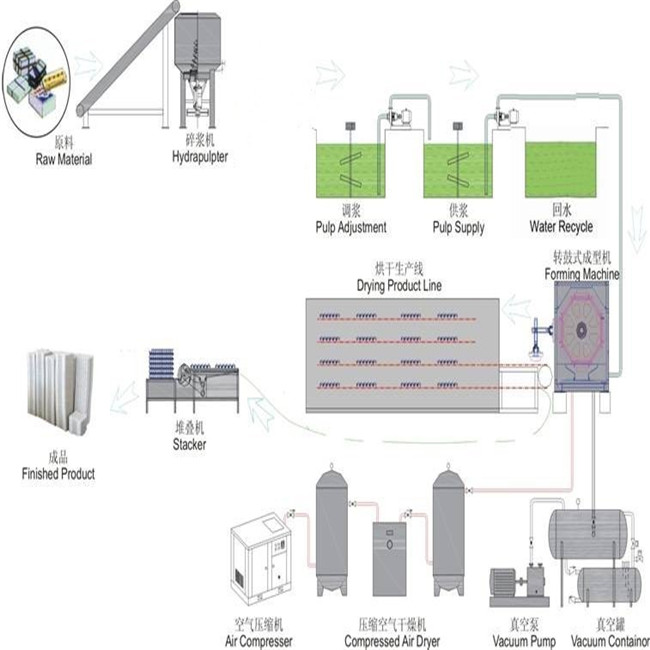

Poultry egg tray making machine equipment includes:

egg tray machine host, pulper, vacuum pump, air compressor, air storage tank, negative pressure pipe, stirring, slurry pump, link pipe, slurry pool, etc.

As a large egg tray machine, the 5X12 egg tray machine is generally used with a dryer. The drying methods are divided into brick kiln drying and metal drying. The specific choice depends on your actual local conditions. Brick kiln drying is cheap but takes up a lot of space. Metal drying occupies a small area but is more expensive.

Poultry egg tray making machine Paper Pulping Process

After the waste paper is crushed with a hydraulic pulper and water for 20 minutes, the paper becomes pulp and flows into the pulp pool.

The pulp is then adjusted for consistency in a homogenizer. The pulp flows into the finished pulp tank after uniform mixing.

Poultry egg tray making machine Paper Egg Tray Molding Process

Through a vacuum pump, the pulp enters the forming machine. Absorbed by vacuum extrusion, the pulp forms an egg tray. The egg tray is blown from the forming mold to the transfer mold.

Poultry egg tray making machine Paper Drying Process (optional)

The egg trays are sent to the metal egg tray dryer by automatic conveyor belt. There are about six layers of belt conveyors in the drying room. The drying time is about 15-20 minutes. This system includes circulation fans and hot air circulation. High drying efficiency.

Poultry egg tray making machine Paper Packing Process (optional)

huatao Group offers collectors and balers. The collectors will pack the egg trays into piles. Balers will pack egg trays in a small space.

Data sheet for Poultry egg tray making machine

Capacity : 4000-5000pcs per hour

Dryer type : Brick oven drying type; Metal oven drying type

Waste paper consumption : 280KG/H

Water consumption : 560KG/H

Electricity consumption : 112-137KW/H

Worker required : 4-6 people per shift

Workshop required : Based on the dryer type

5000-6000pcs egg tray per hour egg tray machine

Capacity : 5000-6000pcs per hour

Dryer type : Brick oven drying type; Metal oven drying type

Waste paper consumption : 350G/H

Water consumption : 700KG/H

Electricity consumption : 112-137KW/H

Worker required : 4-6 people per shift

Workshop required : Based on the dryer type

7000-8000pcs egg tray per hour egg tray machine

Capacity : 7000-8000pcs per hour

Dryer type : Brick oven drying type; Metal oven drying type

Waste paper consumption : 490G/H

Water consumption : 980KG/H

Electricity consumption : 137-267KW/H

Worker required : 4-6 people per shift

Workshop required : Based on the dryer type

HUATAO PROVIDES PULP MOLDING EQUIPMENT & PLASTIC MOLD EQUIPMENT & EGG TRAY MACHINE

Contact us today and let our team of professional technicians guide you through every step of your project. We look forward to working with you and providing successful solutions that meet your unique requirements.

Related Keywords