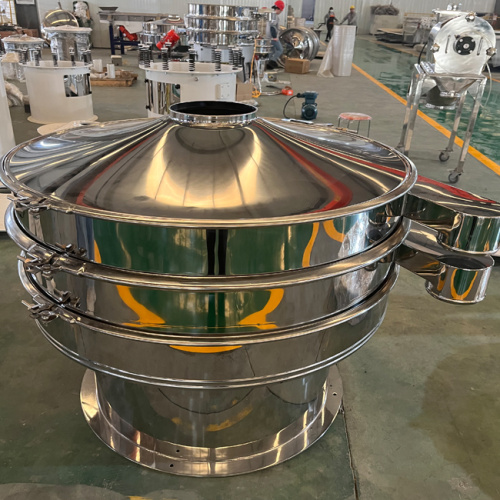

Double Deck Circular Vibratory Screener For condiments

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Qingdao, Shanghai, Tianjin

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 500 sets per month |

| Supply Ability: | 500 sets per month |

| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP,Express Delivery |

| HS Code: | 84741000 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Qingdao,Shanghai,Tianjin |

Triple Deck Circular Vibratory Screener For condiments

Circular Vibratory Screener Principle

In the food industry, condiments are an indispensable part. The screening technology in the condiment production process is a very important link. The condiment rotary vibrating screen can separate the bulk materials of different particle sizes into several different levels through a single or multi-layer screen surface with uniform holes, and stratify them according to the particle size, forming an arrangement rule with small particles at the bottom and coarse particles at the top.

For different types of condiments, the screening requirements are also different. For example, pepper powder requires a screening mesh of 50-60 mesh and an output of 5 cubic meters/h; while the screening mesh of chili powder is 40-45 mesh and the output is 500kg/h. The screening mesh range of turmeric powder is wider, 60-500 mesh, and the output is between 100-700 kg/h; the screening mesh of mustard powder is 30-45 mesh, and the output can reach 300-700 kg/h. By mastering these screening requirements, manufacturers can choose suitable screening equipment to meet production needs.

We are committed to help customer improve capactity & sieving precision based on our Superior quality Sieving machine ( Vibro Separator, Tumbler Screen, Gyratory Sifter,etc)

Circular Vibratory Screener Features

1. High efficiency, refined design, duration, any powders and mucilage are suitable for using.

2. Easily to replace the screen, simple operation and convenience washing.

3. Never jam the hole meshwork, no powder flying, filter size of the powder between 500 mesh and 0.028 mm.

4. Discharge the impurity and coarse materials automobile and operates continuously.

5. Unique screen flame design, long duration of screen, only 3-5 to replace the screen.

6. Small volume, move easily.

7. The highest layers of the screen are about 5 layers. But 3 layers are suggested.

Circular Vibratory Screener Application in customer working site.

How to Choose Suitable Circular Vibratory Screener for your condiments? Pls advise below point.

1. Name of the material: _____

2. Material characteristics: (e.g. specific gravity, bulk density, water content, fluidity, adhesion, electrostatic properties, etc.)

3. Estimated processing capacity per hour:_______(ton/h)

4. How many layers do you need:_______

5. Mesh size of each layer:______ mesh/micron/mm

6. Particle Size Distribution (PSD) of each material size.

Related Keywords