Tapioca Starch Tumbler Screen Machine

-

$1000.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land, Air, Express

- Port:

- shanghai, tianjin, beijing

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 sets per year |

| Supply Ability: | 100000 sets per year |

| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CIP,CPT,Express Delivery |

| Transportation: | Ocean,Land,Air,Express |

| Port: | shanghai,tianjin,beijing |

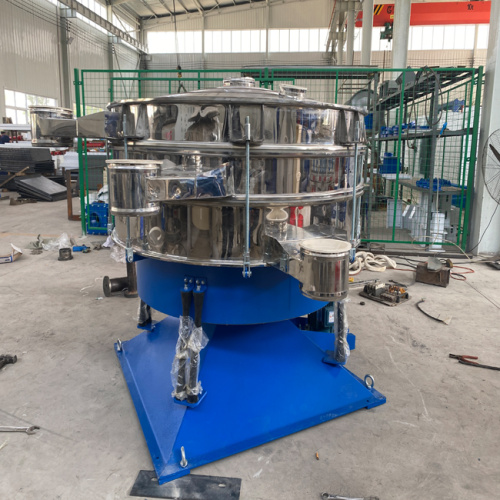

Tapioca Starch Tumbler Screen Machine

Introduction to Screening Process

Tapioca starch / Cassava starch is a functional ingredient widely used in food, medicine, cosmetics and other fields. Its production requires multiple process flows, among which screening is one of the important processes. Generally speaking, in the production process, the cassava slurry needs to be washed, chopped, soaked, stirred, precipitated, washed and other processes to obtain starch slurry. After the starch slurry is centrifuged or vacuum filtered, it needs to be screened to separate the starch particles from other impurities.

Commonly used screen mesh

The sieving of Tapioca starch / Cassava starch need different screen mesh in order to separator the starch particle and other impurity. Commonly used screen mesh are 60 mesh, 80 mesh, 100 mesh and 120 mesh. Among them, 60 mesh can initially separate the starch slurry and remove large impurities and deformed particles; the 80 mesh can further separate and remove smaller impurities and incomplete starch particles; the 100 mesh can separate starch particles from smaller impurities; the 120 mesh can obtain relatively pure starch particles.

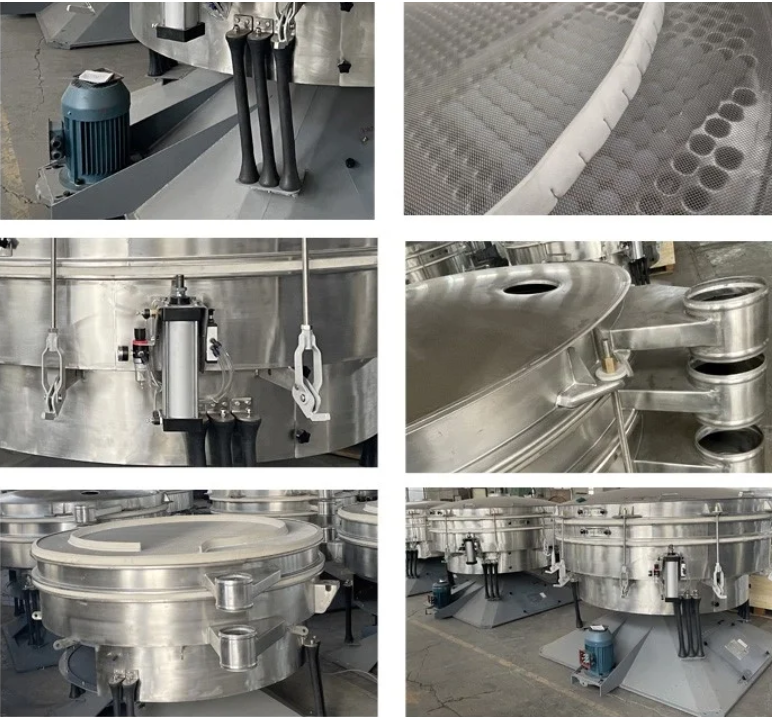

Details of Our Tumbler Screen

Screening effect and influencing factors

The effect of cassava starch screening depends on factors such as thescreen mesh and the impurity content. Generally, the higher the screen mesh size and the lower the impurity content, the purer the starch particles obtained. At the same time, factors such as the pH value, concentration, and temperature of the starch slurry before screening will also have a certain impact on the screening effect. Therefore, in actual production, it is necessary to select the appropriate Tumbler Screen & screen mesh and screening process parameters according to the quality requirements and process characteristics of Tapioca starch / Cassava starch.

Tumbler Screen Machine Working Site At Tapioca starch / Cassava starch.

Related Keywords