Coffee Cup Package Production Line

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land

- Port:

- Shanghai, Tianjin, Qingdao

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | china |

|---|---|

| Productivity: | 10-20 set per month |

| Supply Ability: | 10-15 sets per month |

| HS Code: | 84413010 |

| Transportation: | Ocean,Land |

| Port: | Shanghai,Tianjin,Qingdao |

A coffee cup holder production line typically Molded Pulp Machine involves a series of machines and processes to manufacture coffee cup holders in a high-volume and efficient manner. Here are the key steps and equipment involved in a typical coffee cup holder production line:

1. Material Preparation: The production line begins with the preparation of the raw materials. The primary material used for coffee cup holders is usually paperboard or corrugated cardboard. The raw material is sourced in the form of large rolls or sheets.

2. Printing and Die Cutting: The paperboard or cardboard is fed into a printing machine where the desired graphics, logos, or branding elements are printed onto the material. After printing, the material moves on to a die-cutting machine, which cuts the paperboard or cardboard into the shape of the coffee cup holder.

3. Folding and Gluing: The die-cut coffee cup holder blanks are then fed into a folding and gluing machine. This machine folds the blanks along pre-scored lines and applies adhesive to the appropriate areas to secure the folded shape of the cup holder.

4. Drying or Curing: In some cases, the glued coffee cup holders may need to go through a drying or curing process to ensure that the adhesive sets properly. This step may involve passing the holders through a heated chamber or using other methods to accelerate the drying process.

5. Quality Control: Throughout the production line, quality control measures are implemented to check for any defects, such as misprints, improper folding, or insufficient adhesive. Inspection may be done manually or with the assistance of automated systems.

6. Packaging and Stacking: Once the coffee cup holders are deemed to meet the quality standards, they are typically packaged into bundles or stacks. Packaging may involve shrink-wrapping, placing the holders in boxes, or other suitable methods for transportation and storage.

7. Optional Additional Processes: Depending on specific requirements, additional processes may be included in the production line. For example, if the coffee cup holders are to be customized with additional features like handles or sleeves, separate machines or assembly stations may be incorporated into the line to add these elements.

8. Automation and Conveyor Systems: To optimize efficiency and productivity, coffee cup holder production lines often incorporate automation and conveyor systems. These systems facilitate the smooth transfer of materials between machines and minimize manual handling.

9. Maintenance and Machine Servicing: Regular maintenance and servicing of the machines and equipment in the production line are essential to ensure their optimal performance. This includes routine cleaning, lubrication, and inspection to address any issues and prevent downtime.

Coffee cup holder production lines Molded Pulp Machine can vary depending on the specific manufacturing processes and equipment used by different manufacturers. The line may be customized to accommodate different sizes, shapes, and designs of coffee cup holders based on market demands.

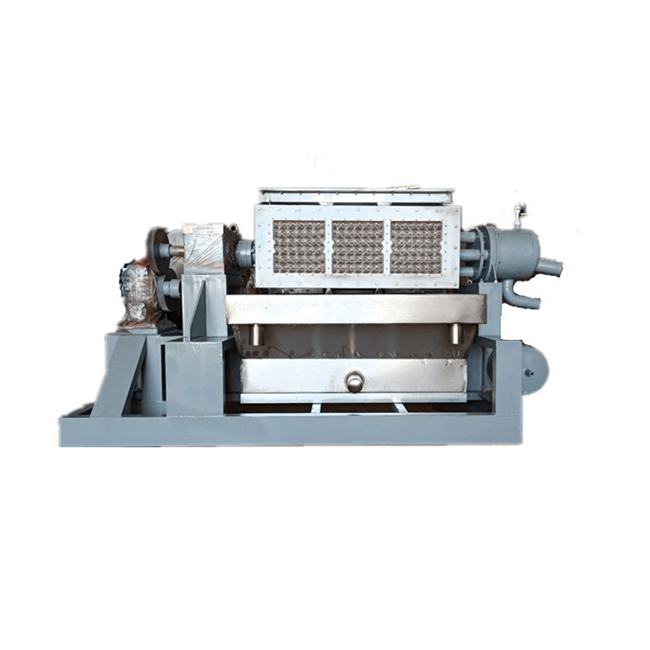

1. Molded Pulp Machine : Pulp molding machines are the core equipment in the production line. These machines are designed to convert pulp, usually made from recycled paper or cardboard, into molded coffee cup holders. The machines feature molds that shape and form the pulp into the desired holder design.

2. Pulp Preparation System: The production line includes a pulp preparation system that processes the recycled paper or cardboard into a pulp consistency suitable for molding. This system typically involves steps such as pulping, blending, and screening to remove impurities and create a homogenous pulp mixture.

3. Molding Tools and Dies: The production line incorporates various molding tools and dies to shape the pulp into coffee cup holders. These tools and dies are designed to match the specific size and shape requirements of the holders. They can be customized and interchangeable to accommodate different cup sizes and designs.

4. Drying System: After the pulp is molded into cup holders, a drying system is employed to remove moisture and solidify the holders. This system may consist of drying chambers or conveyor belts equipped with heating elements or hot air circulation to facilitate the drying process.

5. Automation and Conveyor Systems: To enhance efficiency and productivity, coffee cup pulp mold holder production lines often incorporate automation and conveyor systems. These systems automate the movement of molded holders between different stages of the production process, such as pulp loading, molding, drying, and stacking.

6. Quality Control and Inspection: Quality control measures are an integral part of the production line. Inspection stations or automated systems are implemented to check for defects, such as incomplete molding, improper drying, or inconsistent shape. Any defective holders are identified and removed from the production line.

7. Stacking and Packaging: Once the coffee cup holders are fully dried and inspected, they are stacked and packaged for storage or shipping. Stacking machines or robots may be employed to organize and stack the holders into bundles or pallets. Packaging materials, such as plastic wrap or corrugated boxes, are used to protect and secure the stacked holders.

8. Maintenance and Servicing: Regular maintenance and servicing of the machines and equipment in the production line are crucial for their optimal performance. This includes routine cleaning, lubrication, and inspection to address any issues and ensure smooth operation.

.

Coffee cup pulp mold holder production lines Molded Pulp Machine can be configured and customized based on specific requirements, such as production capacity, holder design, and automation level. The features mentioned above provide a general overview of the components typically found in such production lines, but the exact configuration and features may vary depending on the manufacturer and specific production needs.

HUATAO PROVIDES PULP MOLDING EQUIPMENT & PLASTIC MOLD EQUIPMENT & EGG TRAY MACHINE

Including:

Pulp Mold Machine

Egg Tray Molding Machine

Egg Carton Molding Machine

Fruit Tray Molding Machine

Molded Fiber Tableware Machine

Molded Pulp Machine

Hot Press Shaping Machine

Mold For Pulp Molded Machine

Pulp Mold Stacker

PE Rope Pulp Mold Packing Machine

By working with our technical team, you benefit from our extensive industry experience and access to a wide range of resources. We are committed to achieving your project goals and exceeding your expectations.

Related Keywords