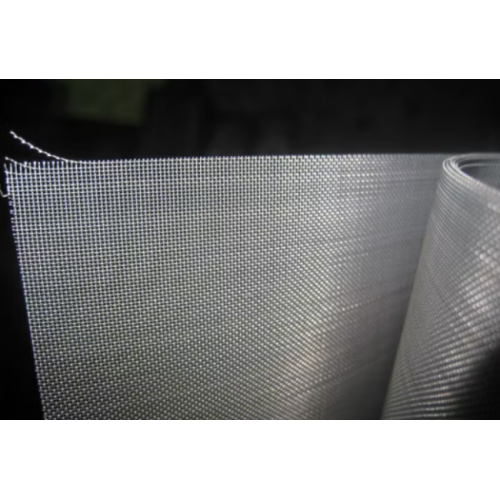

Pulp Molding Process Stainless Steel Wire

-

USD20≥1 Square Meter

- Min. Order:

- 1 Square Meter

- Min. Order:

- 1 Square Meter

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shanghai, Tianjin, Qingdao

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Productivity: | 200000m2/month |

| Supply Ability: | 200000m2/month |

| HS Code: | 7314140000 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shanghai,Tianjin,Qingdao |

Product Description

Product Description

Pulp Molding Process Stainless Steel Wire

Introducing stainless steel wire for pulp forming: a revolution in sustainable manufacturing

In an era where sustainability and innovation go hand in hand, Pulp Forming Fabric stands out as a breakthrough solution for manufacturers seeking to increase production capacity while minimizing environmental impact. This product is more than just a tool; it is a testimony to the future of environmentally friendly manufacturing, combining advanced technology with sustainable principles.

What is the pulp forming process like?

The pulp forming process is a complex manufacturing technology that transforms recycled paper and other fiber materials into formed products. The process is not only efficient, but also environmentally friendly because it utilizes waste materials that would otherwise lead to overflowing landfills. By adopting this method, manufacturers can produce a variety of products from packaging materials to disposable tableware while promoting a circular economy.

At the heart of this process is the use of pulp, which is derived from natural fibers. The pulp is mixed with water to form a slurry, which is then shaped into a variety of products. The shaped items are dried and ready for use. This method not only reduces waste but also saves resources, making it a preferred choice for companies committed to sustainable development.

The role of stainless steel wire in the pulp forming process

The introduction of stainless steel wire into the pulp forming process marks a significant advancement in the manufacturing industry. This wire has a variety of uses that can improve the efficiency and effectiveness of the forming process. Here are some of the ways:

1. Structural Integrity: Stainless steel wire provides the necessary support and structure for the pulp mold. Its strength and durability ensure that the mold maintains its shape during the drying process, resulting in a high-quality finished product.

2. Heat resistance: The pulp forming process often involves drying the formed product at high temperatures. Stainless steel wire can withstand these conditions without bending or degradation, ensuring consistent performance throughout the manufacturing cycle.

3. Corrosion resistance: One of the outstanding features of stainless steel is corrosion resistance. In a humid manufacturing environment, the use of stainless steel wire helps maintain the integrity of the mold and prevents contamination of pulp products.

4. Reusable: Unlike traditional materials that may wear out over time, stainless steel wire can be reused many times without losing its effectiveness. This not only reduces costs for manufacturers, but also conforms to sustainable practices by minimizing waste.

5. Precision Engineering: Using stainless steel wire enables precision engineering of molds, allowing manufacturers to create complex designs and shapes that were previously difficult to achieve. This opens up new possibilities for product innovation and customization.

Benefits of using pulp-formed stainless steel wire

Incorporating stainless steel wire into the pulp forming process offers manufacturers many benefits, including:

1)Improved Product Quality: The structural support provided by stainless steel wire results in a more uniform, higher quality molded product. This is critical for businesses that prioritize product quality and consistency.

2)Cost Effective: While the initial investment in stainless steel wire may be higher than traditional materials, the long-term savings from reduced maintenance, increased durability, and reusability make it a cost-effective choice.

3)Sustainability: By utilizing recycled materials and incorporating stainless steel wire into the pulp forming process, manufacturers can significantly reduce their carbon footprint. This commitment to sustainability resonates with the growing number of consumers seeking environmentally friendly products.

4)Versatility: The pulp forming process can be used to manufacture a wide range of products, from food packaging to industrial components. The addition of stainless steel wire enhances this versatility, allowing for the production of more complex and diverse items.

5)Improved Production Efficiency: The durability and reliability of stainless steel wire helps make the production process smoother. Manufacturers can reduce interruptions and delays, thereby increasing output and profitability.

Application of stainless steel wire in pulp forming process

The applications for stainless steel wire for pulp forming are wide and varied. Here are some of the key areas where this innovative product is having a significant impact:

1. Food Packaging: As the demand for sustainable packaging solutions continues to grow, pulp forming processes are being used to create biodegradable food containers. The addition of stainless steel wire ensures that these containers maintain their shape and integrity even in harsh conditions.

2. Consumer Products: From disposable plates to eco-friendly cups, the versatility of the pulp forming process enables manufacturers to produce a wide variety of consumer products that meet the needs of environmentally conscious consumers.

3. Industrial Applications: The strength and durability of stainless steel wire makes it ideal for manufacturing industrial parts that require precision and reliability. This includes items such as pallets, trays, and protective packaging.

4. Agricultural products: The pulp molding process can also be used to make biodegradable seed trays and flower pots, promoting sustainable agricultural practices and reducing plastic waste in agriculture.

5. Medical supplies: In the medical field, the demand for sterile and disposable products is crucial. The pulp forming process combined with stainless steel wire can produce high-quality medical packaging that meets strict hygiene standards.

In summary

Pulp forming stainless steel wire is more than just a product; it represents a shift toward sustainable manufacturing practices that prioritize quality, efficiency, and environmental responsibility. By incorporating stainless steel wire into the pulp forming process, manufacturers can increase production capabilities while contributing to a greener future.

HUATAO PROVIDES PULP MOLDING EQUIPMENT & Plastic Mold Equipment & Egg Tray machine Including:

Pulp Mold Machine

Egg Tray Molding Machine

Egg Carton Molding Machine

Fruit Tray Molding Machine

Molded Fiber Tableware Machine

Molded Pulp Machine

Hot Press Shaping Machine

Mold For Pulp Molded Machine

Pulp Mold Stacker

PE Rope Pulp Mold Packing Machine

By working with our technical team, you benefit from our extensive industry experience and access to a wide range of resources. We are committed to achieving your project goals and exceeding your expectations.

Related Keywords

Related Keywords