Pulp Molding Process Custom SS Wire 40/50 Mesh

-

USD20≥1 Square Meter

- Min. Order:

- 1 Square Meter

- Min. Order:

- 1 Square Meter

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shanghai, Tianjin, Qingdao

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Productivity: | 200000m2/month |

| Supply Ability: | 200000m2/month |

| HS Code: | 7314140000 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shanghai,Tianjin,Qingdao |

Product Description

Product Description

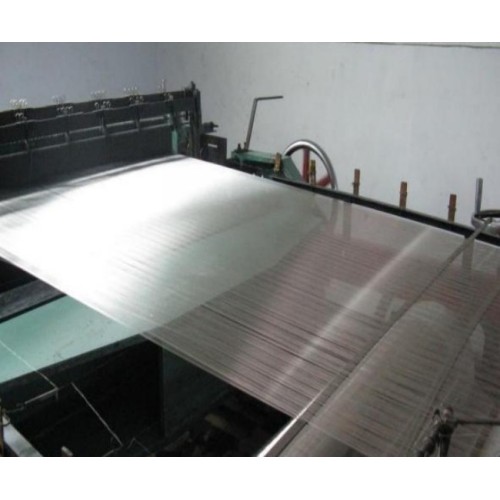

Pulp Molding Process Custom Stainless Stell Wire 40/50 Mesh

Pulp Forming Process Introduction Customized Stainless Steel Wire 40/50 Mesh

In the ever-evolving world of manufacturing and production, the need for high-quality materials that can withstand rigorous processes is paramount. Custom Stainless Steel Wire 40/50 Mesh for Pulp Forming Processes - Products designed to meet the needs of a wide range of industries while ensuring durability, efficiency and versatility. This innovative solution is more than just a product; it is a game changer for those who need reliable materials for their operations.

What is the pulp forming process like?

Before diving into the specifics of stainless steel wire, it’s crucial to understand the pulp forming process itself. This method is widely used to produce environmentally friendly packaging, disposable cutlery, and a variety of molded products. The process involves using recycled pulp, forming it into specific shapes, and then drying it to create strong, lightweight items. The versatility of pulp forming makes it an attractive option for manufacturers who want to reduce their environmental impact while maintaining high-quality output.

The role of stainless steel wire in pulp forming

At the heart of the pulp forming process is the need for a reliable support structure that can withstand the stresses of forming and drying. This is where our custom 40/50 stainless steel wire mesh comes in. Designed specifically for the pulp forming industry, this mesh offers unrivalled strength and durability, ensuring your formed product retains its shape and integrity throughout the production process.

Main features of 40/50 stainless steel wire mesh

1. **High Strength and Durability**: Our stainless steel wire is engineered to withstand the rigors of the pulp forming process. Its 40/50 mesh size provides a perfect balance between strength and flexibility, making it ideal for a variety of applications.

2. **Corrosion Resistant**: Stainless steel is known for its resistance to rust and corrosion, which is critical in wet environments. This feature ensures your wire mesh will last longer, reducing the need for frequent replacement and maintenance.

3. **Customizable Options**: We understand that every business has unique needs. That’s why we offer customizable options for our stainless steel wire. Whether you require a specific size, coating, or surface treatment, we can customize our products to meet your exact specifications.

4. **Easy Installation**: Our stainless steel wire mesh is easy to install, allowing manufacturers to seamlessly integrate it into existing pulp forming processes. This ease of use reduces downtime and increases productivity.

5. **VERSATILE APPLICATIONS**: While our stainless steel wire is specifically designed for the pulp forming process, its versatility means it can also be used in a variety of other applications including filtration, reinforcement and construction. This makes it a valuable addition to any maker’s toolkit.

Benefits of using pulp forming process Custom stainless steel wire 40/50 mesh

1. **Improve Product Quality**: By using our stainless steel wire, manufacturers can ensure that their molded products maintain their shape and quality throughout the production process. This can increase customer satisfaction and reduce returns.

2. **Cost-Effective Solution**: Investing in high-quality materials like our stainless steel wire can save you a lot of money in the long run. With its durability and wear resistance, businesses can reduce material costs and increase profitability.

3. **Sustainability**: The pulp forming process itself is an environmentally friendly alternative to traditional manufacturing methods. By adopting our stainless steel wire, manufacturers can further enhance their sustainability efforts and contribute to a greener planet.

4. **Increased Efficiency**: Easy installation and numerous customization options allow manufacturers to streamline the production process. Increased efficiency can reduce turnaround time and increase overall productivity.

5. **Reliable Support**: Our stainless steel wires provide the necessary support for molded products, ensuring they maintain their shape and integrity during the drying process. This reliability is critical for manufacturers who value quality and consistency.

Why choose us?

When sourcing materials for your manufacturing process, you need a partner you can trust. Our commitment to quality, innovation, and customer satisfaction sets us apart from the competition. Here are the reasons why you should choose our custom stainless steel wire 40/50 mesh for your pulp forming process:

- **Expertise**: With years of industry experience, we understand the unique challenges manufacturers face. Our team of experts is here to provide guidance and support, ensuring you find the right solution for your needs.

- **QUALITY GUARANTEED**: We pride ourselves on our rigorous quality control process. Each batch of stainless steel wire is thoroughly tested to ensure it meets our high standards and your expectations.

- **Customer-centric approach**: Your satisfaction is our top priority. We work closely with our clients to understand their needs and provide tailored solutions to drive success.

- **COMPETITIVE PRICING**: We believe high quality materials shouldn't be too expensive. Our competitive pricing ensures you get the best value for your investment.

In summary

In today's world, where quality and sustainability are more important than ever, Pulp Forming Process Custom Stainless Steel Wire 40/50 Mesh is an excellent choice for manufacturers. With its superior strength, corrosion resistance and versatility, this product is designed to enhance your production process and deliver outstanding results.

Whether you are in the pulp forming industry or are looking for a reliable wire mesh solution for other applications, our stainless steel wire is your best choice. Experience the difference that high-quality materials can make in your operations. Contact us today to learn more about our custom stainless steel wire 40/50 mesh for pulp forming processes and how it can benefit your business. Let’s work together to create a more sustainable and efficient future.

HUATAO PROVIDES PULP MOLDING EQUIPMENT & Plastic Mold Equipment & Egg Tray machine Including:

Pulp Mold Machine

Egg Tray Molding Machine

Egg Carton Molding Machine

Fruit Tray Molding Machine

Molded Fiber Tableware Machine

Molded Pulp Machine

Hot Press Shaping Machine

Mold For Pulp Molded Machine

Pulp Mold Stacker

PE Rope Pulp Mold Packing Machine

By working with our technical team, you benefit from our extensive industry experience and access to a wide range of resources. We are committed to achieving your project goals and exceeding your expectations.

Related Keywords

Related Keywords