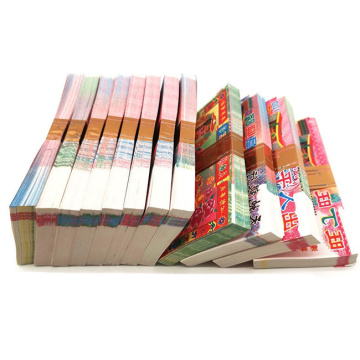

Stainless Steel Wire For Pulp Mold Accessories

-

USD20≥1 Square Meter

- Min. Order:

- 1 Square Meter

- Min. Order:

- 1 Square Meter

- Port:

- Shanghai, Tianjin, Qingdao

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Productivity: | 200000m2/month |

| Supply Ability: | 200000m2/month |

| HS Code: | 7314140000 |

| Port: | Shanghai,Tianjin,Qingdao |

Product Description

Product Description

Stainless Steel Wire For Pulp Mold Accessories

In the world of manufacturing and production, the importance of quality materials cannot be overstated. One material that has received a lot of attention in recent years is stainless steel wire, especially when it comes to pulp mold parts. This article takes an in-depth look at the importance of stainless steel wire for pulp molds, its applications, and why it is the preferred choice across industries.

Understanding Pulp Forming

Pulp forming is a process that makes products from recycled pulp. This environmentally friendly manufacturing technique is widely used to produce packaging materials, pallets, and other formed products. The process is not only sustainable but also cost-effective, making it a popular choice for manufacturers looking to reduce their environmental impact.

The pulp forming process typically involves multiple stages, including pulping, forming, drying and finishing. Each stage requires specific tools and accessories to ensure efficiency and quality. One of the key components of the process is the pulp mold itself, and this is where stainless steel wire comes into play.

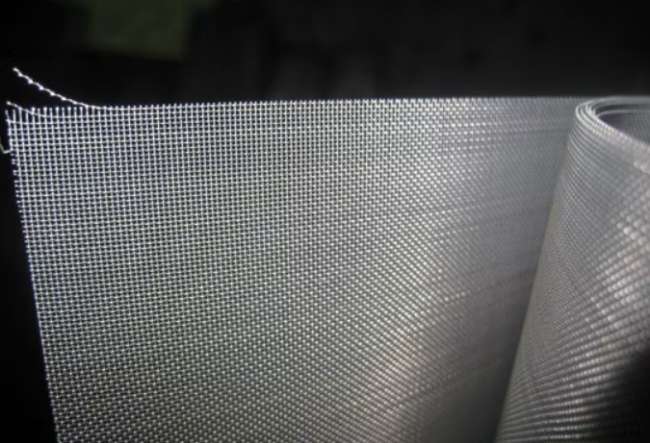

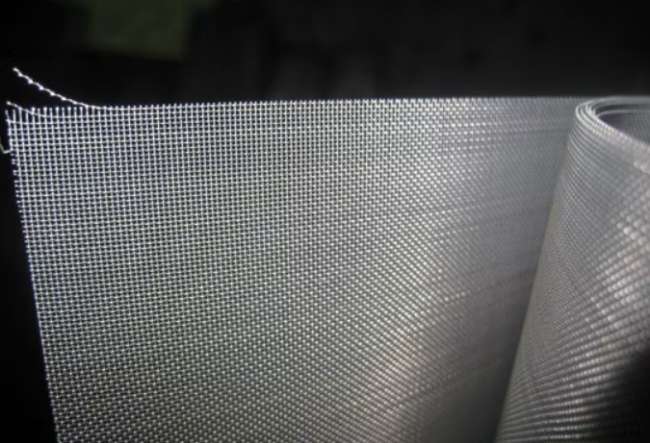

The role of stainless steel wire in pulp mold

Stainless steel wire is an essential accessory in the pulp molding process. It is mainly used to reinforce the structure of pulp molds, ensuring that they maintain their shape and integrity during the production process. Using stainless steel wire in pulp molds has several advantages:

1. Durability and Strength

One of the most significant advantages of using stainless steel wire in pulp molds is its durability. Stainless steel is known for its high tensile strength, which means it can withstand the pressure and stress of the molding process. This durability ensures that the mold can be reused many times without losing its shape or functionality.

2. Corrosion resistance

Pulp molding often involves exposure to moisture and various chemicals. Stainless steel wire is highly resistant to corrosion, making it an ideal choice for pulp molding accessories. This corrosion resistance ensures that the wire maintains its structural integrity over a long period of time, reducing the need for frequent replacement and repairs.

3. High temperature resistance

The pulp forming process can involve high temperatures, especially during the drying stage. Stainless steel wire can withstand these temperatures without deforming or losing its properties. This feature is essential to maintaining the quality of the formed product.

4. Versatility

Stainless steel wire is available in a variety of gauges and shapes, allowing manufacturers to select the right type for their specific needs. Whether it is used to reinforce molds or create intricate designs, the versatility of stainless steel wire makes it a valuable asset in pulp molding.

Application of pulp molding stainless steel wire

The applications of stainless steel wire in pulp molds are very wide and varied. Here are some of the most common uses:

1. Packaging Solutions

One of the main applications of pulp molding is the production of packaging materials. Pulp molding stainless steel wire is used to create strong and reliable packaging solutions for fragile items, ensuring they are protected during transportation and storage.

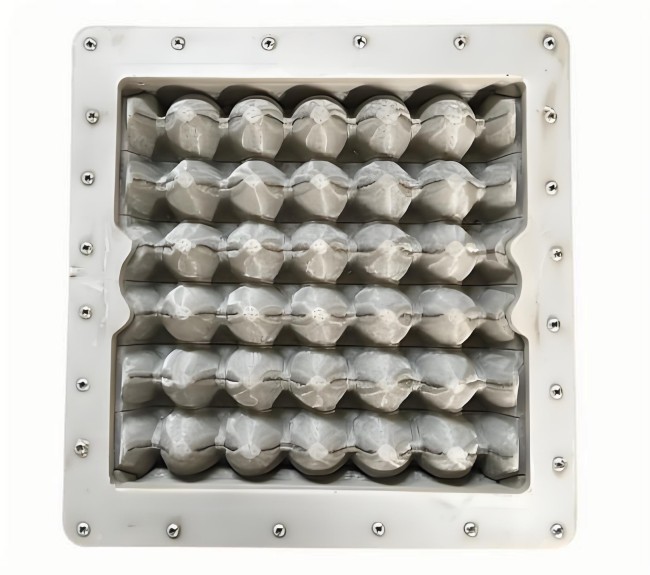

2. Food Industry

In the food industry, molded pulp products are often used to package and hold food. The use of stainless steel wire in these molds ensures that the product is safe, sanitary, and can withstand the rigors of food processing and handling.

3. Electronics

The electronics industry is increasingly using molded pulp trays and packaging to protect sensitive components during shipping. The strength and durability of the stainless steel wire in these molds helps prevent damage to electronic components.

4. Consumer goods

Pulp molded products are used in a variety of consumer products, from cosmetics to household items. The addition of stainless steel wire to these molds increases their strength and reliability, making them suitable for a wide range of applications.

## in conclusion

In conclusion, stainless steel wire plays a key role in the production of pulp mold accessories. Its durability, corrosion resistance, high temperature resistance, and versatility make it an ideal choice for reinforcing pulp molds. As the industry continues to seek sustainable and efficient manufacturing solutions, the demand for pulp mold SS wire is likely to grow.

Manufacturers looking to improve their pulp forming process should consider the benefits of incorporating stainless steel wire into their molds. By doing so, they can improve product quality, reduce waste, and contribute to a more sustainable future. As the world moves toward more environmentally friendly practices, the role of materials such as stainless steel wire in pulp forming will undoubtedly become more critical.

HUATAO PROVIDES PULP MOLDING EQUIPMENT & Plastic Mold Equipment & Egg Tray machine Including:

Pulp Mold Machine

Egg Tray Molding Machine

Egg Carton Molding Machine

Fruit Tray Molding Machine

Molded Fiber Tableware Machine

Molded Pulp Machine

Hot Press Shaping Machine

Mold For Pulp Molded Machine

Pulp Mold Stacker

PE Rope Pulp Mold Packing Machine

By working with our technical team, you benefit from our extensive industry experience and access to a wide range of resources. We are committed to achieving your project goals and exceeding your expectations.

Related Keywords

Related Keywords