Pulp Equipment HDC High Consistency High Density Cleaner

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Air

- Port:

- SHANGHAI, TIANJIN, BEIJING

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|---|

| Productivity: | 100 sets/month |

| Supply Ability: | TIMELY DELIVERY |

| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,CPT,CIP,DDP |

| Certificate: | ISO |

| HS Code: | 84399100 |

| Transportation: | Ocean,Air |

| Port: | SHANGHAI,TIANJIN,BEIJING |

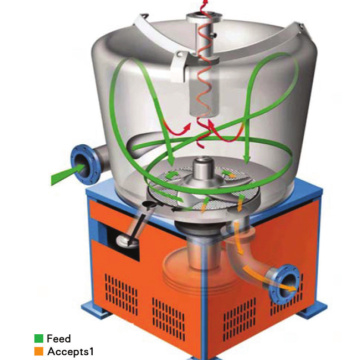

Pulp Equipment HDC High Consistency High Density Cleaner

High Density Cleaner / High Consistency Cleaner

It can eliminate heavy impurities larger than 3mm in diameter from recycled paper stock.

As coarse screening equipment, it is usually downstream equipment of hydrapulper. It can also be installed as an important piece of equipment to ensure the operation of downstream processing equipment.

Pulper Equipments Cleaner is used for getting rid of heavy impurities and parts of light impurities, suitable for purifying high, middle and low consistency pulp. Reducing different between inlet and outlet, save energy by 25% - 35%.

Cleaner Features:

The Cleaner is made of stainless steel upper part, the lower part of wear-resistant ceramic, the inner wall of the body in a spiral cone design.

It can be used in the pulp purification system to remove waste slurry mixed, wax, adhesive, plastic film, foam, gas, sand, iron and other light and heavy impurities.

HD Cleaner Type

| Type | HT-11 | HT-12 | HT-13 | HT-14 | HT-15 | HT-16 | HT-17 |

| Throughput (L/min) | 800-1200 | 1400-1800 | 2000-2800 | 3000-4500 | 5000-6000 | 6500-8000 | 9000-12000 |

| Inlet Density (%) | (H) 2.5-5 (M) 1-2.5 | ||||||

| Inlet Pressure (MPa) | 0.15 -- 0.35 | ||||||

| Reject | Auto & Manual | ||||||

Huatao Service:

Pre-sales service:

Offering comprehensive technical and business consultation services.

Proposing the most suitable scheme and equipment for our clients.

Designing and fabricating targeted products according to the special requirements of clients.

Training periodically high qualified service technician.

After-sales service:

Assisting our clients for foundation construction of equipment.

Dispatching engineers to install and debug equipment.

Regularly visit clients to solve production problems.

Huatao Supply all the spare parts and Pulp cleaning equipment, Pulp screening equipment for Paper mills.

Stock preparation: Conveyor belt, Pulper, D Pulper, hydrapulper, Cleaner, HD Cleaner, LD clenaer, Pressure screen, Screen basket, Hole type screen basket, Slot screen basket, , Pressure Screen, Cleaner,Fine Screen, Vibrating Screen, High Consistency Cleaner, Low Consistency Cleaner, Reject Separator, Float Purger, Fiber Fractionating Screen, Washer, Disc thickener, Refiner, DDR, Refiner disc, Refiner plate, Screen plate, and so on.

Paper machine spare parts: PMC - Paper machine clothing, forming fabric, dryer screen, press felt, polyester fabric, SS wire mesh, shrinking mesh, Dewatering elements, Breast roll, Guide roll, Forward roll, Vacuum couch roll, Drive roll, Curved roll, Calender roll, Pope reel, Rewinder, Slitter machine, Sizing machine, Calender machine, Cylinder mould, Dryer cylinder, and so on.

Related Keywords