Twin Wire Press Heat Disperser For Pulp Washing/Dewatering

-

$40000.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Air

- Port:

- SHANGHAI, TIANJIN, BEIJING

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|---|

| Productivity: | 100sets/month |

| Supply Ability: | TIMELY DELIVERY |

| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP,DDP |

| Certificate: | ISO |

| HS Code: | 84399100 |

| Transportation: | Ocean,Air |

| Port: | SHANGHAI,TIANJIN,BEIJING |

Twin Wire Press , Heat Disperser For Paper Pulp Washing / Dewatering

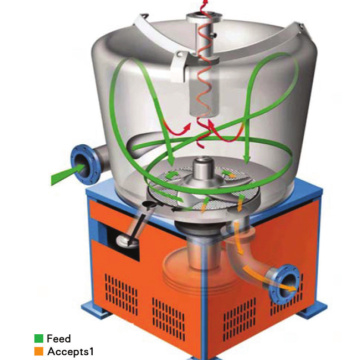

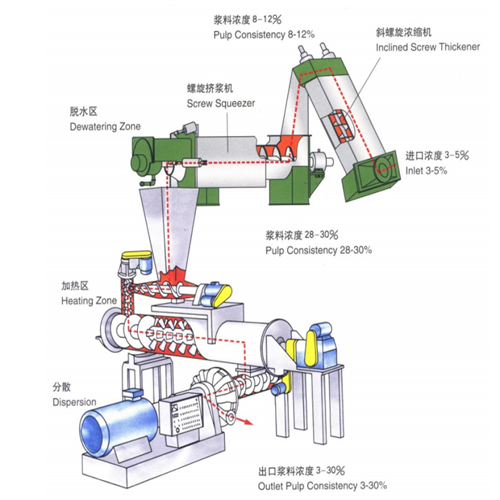

Disc Heat Disperser Description

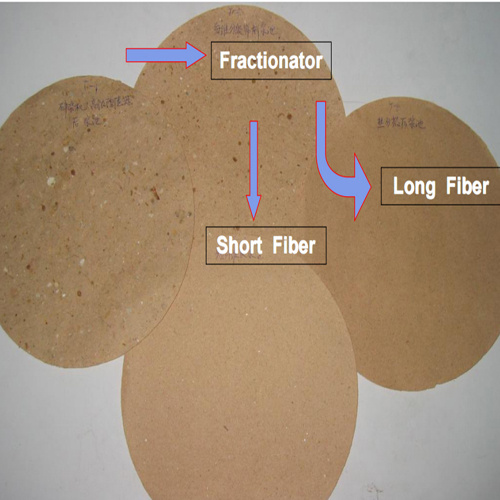

Disc heat disperser, it is one of the indispensable equipment in the pulping and papermaking process using waste paper as raw material. Large ink dots, etc., to ensure more economical and effective production of high-quality recycled pulp. This equipment has the advantages of less fiber cutting, good dispersion effect, no need for disc grinding and beating, and low operating costs. It is suitable for all kinds of waste paper pulping.

At present, Disc Heat-disperser is mostly used for deinking pulping line. When processing white waste paper (ONP, MOW, OMG) to produce high quality, high whiteness paper, Disc Heat-disperser is in the middle of the process, and can be effectively separated printing ink before washing. and disperse ink and hot melt impurities into fine particles to facilitate removal in the flotation and washing process at the back of the process.

Pulper Disc Heat-Disperser is suitable for treating all kinds of pulp using waste paper as raw materials, Floatating-Dispersering-Bleaching Equipment can effectively carry out the dispersing treatment of impurities including sticks, grease, paraffin wax, plastics, rubber or ink particles etc. to improve quality and performance of paper.

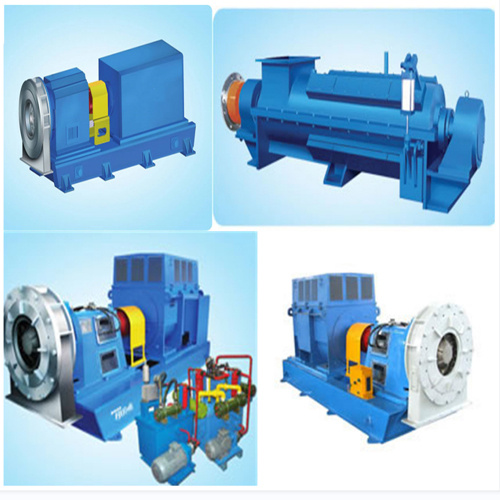

Disc Heat-disperser system mainly includes: Fluffer, Heater, Feed screw conveyor and Disc Heat-disperser.

Besides there is also same function dispersering equipment Kneader. Bleaching Tower and Flatation Machine are also supplied for paper mill.

Disc Heat Disperser Technical Specification

|

Type |

HT-1 |

HT-2 |

HT-3 |

|

Nominal dia.: mm |

Φ450 |

Φ710 |

Φ1050 |

|

Consistency of inflow pulp: % |

25-30 |

||

|

Consistency of outflow pulp: % |

4-12 |

||

|

25-30 |

|||

|

Treating temperature: ℃ |

110-120(AOCC) |

||

|

80-90(ONP) |

|||

|

Capacity of product : t/d |

30-70 |

80-300 |

280-600 |

|

Power of main motor: kw |

110-200 |

280-800 |

630-1250 |

|

Power pf feeding screw:kw |

5.5 |

5.5-11 |

11-18.5 |

|

Power of pulg screw:kw |

15 |

22-45 |

55-90 |

|

Power of fultter:kw |

5.5 |

5.5-11 |

15-18.5 |

|

Power of speedy heater:kw |

7.5 |

7.5-22 |

30-45 |

Huatao Supply all the spare parts and Pulp cleaning equipment, Pulp screening equipment for Paper mills.

Stock preparation: Conveyor belt, Pulper, D Pulper, hydrapulper, Cleaner, HD Cleaner, LD clenaer, Pressure screen, Screen basket, Hole type screen basket, Slot screen basket, , Pressure Screen, Cleaner,Fine Screen, Vibrating Screen, High Consistency Cleaner, Low Consistency Cleaner, Reject Separator, Float Purger, Fiber Fractionating Screen, Washer, Disc thickener, Refiner, DDR, Refiner disc, Refiner plate, Screen plate, and so on.

Paper machine spare parts: PMC - Paper machine clothing, forming fabric, dryer screen, press felt, polyester fabric, SS wire mesh, shrinking mesh, Dewatering elements, Breast roll, Guide roll, Forward roll, Vacuum couch roll, Drive roll, Curved roll, Calender roll, Pope reel, Rewinder, Slitter machine, Sizing machine, Calender machine, Cylinder mould, Dryer cylinder, and so on.

Disc Heat Disperser Picture Show

Related Keywords